All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

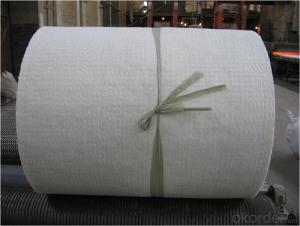

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

How do refractory materials react with different types of slags?

Refractory materials react with different types of slags by forming a protective layer on their surface, which prevents the slag from penetrating and corroding the refractory. This reaction is crucial in maintaining the integrity and durability of refractory linings in high-temperature industrial processes such as metal smelting or glassmaking.

What are the refractory materials used in the ceramic industry?

Refractory materials commonly used in the ceramic industry include alumina, silica, zirconia, and magnesia.

How are refractory materials used in furnaces?

Refractory materials are used in furnaces to line the interior walls and floors, as well as to create various components like crucibles, bricks, and tiles. These materials are designed to withstand high temperatures, chemical corrosion, and mechanical stress, ensuring the integrity and longevity of the furnace. They provide insulation to prevent heat loss, protect the furnace structure from damage caused by molten metal or harsh chemicals, and aid in maintaining a consistent temperature inside the furnace.

Wholesale Refractory Materials from supplier in Djibouti

Our team of highly skilled professionals is dedicated to providing top-notch customer service and ensuring that all your needs are met efficiently and effectively. Whether you require refractory bricks, castables, insulation materials, or any other refractory product, we have the expertise and resources to fulfill your requirements.

In addition to our exceptional product offerings, we also provide comprehensive technical support services. Our team of experts can assist you in selecting the right refractory materials for your specific applications, provide guidance on installation and maintenance procedures, and offer troubleshooting advice whenever needed. We understand the critical role that refractory materials play in various industries, and we strive to ensure that our customers receive the best possible solutions for their unique requirements.

As a subsidiary platform of CNBM, we have access to a vast network of suppliers and manufacturers, enabling us to offer competitive prices and timely deliveries. We understand the importance of cost-effectiveness and efficiency in procurement processes, and we leverage our strong relationships with suppliers to provide seamless and hassle-free procurement solutions to our customers.

Furthermore, our extensive market presence and experience in Djibouti allow us to offer invaluable insights and expertise to enhance the success of your projects. We are well-versed in the local market dynamics, regulations, and industry trends, enabling us to provide tailored solutions that meet your specific needs and requirements. Our goal is to become your trusted partner for all your refractory materials needs in Djibouti, providing exceptional products, services, and support to help you achieve your goals.

Contact us today to discuss your refractory materials requirements and discover how we can add value to your projects.

In addition to our exceptional product offerings, we also provide comprehensive technical support services. Our team of experts can assist you in selecting the right refractory materials for your specific applications, provide guidance on installation and maintenance procedures, and offer troubleshooting advice whenever needed. We understand the critical role that refractory materials play in various industries, and we strive to ensure that our customers receive the best possible solutions for their unique requirements.

As a subsidiary platform of CNBM, we have access to a vast network of suppliers and manufacturers, enabling us to offer competitive prices and timely deliveries. We understand the importance of cost-effectiveness and efficiency in procurement processes, and we leverage our strong relationships with suppliers to provide seamless and hassle-free procurement solutions to our customers.

Furthermore, our extensive market presence and experience in Djibouti allow us to offer invaluable insights and expertise to enhance the success of your projects. We are well-versed in the local market dynamics, regulations, and industry trends, enabling us to provide tailored solutions that meet your specific needs and requirements. Our goal is to become your trusted partner for all your refractory materials needs in Djibouti, providing exceptional products, services, and support to help you achieve your goals.

Contact us today to discuss your refractory materials requirements and discover how we can add value to your projects.

Hot Search

- Monolithic Refractories in Portugal

- Ceramic Fiber Products in Azerbaijan

- Refractory Bricks in Hungary

- Raw Materials For Refractory in Togo

- Ceramic Fiber Products in Zambia

- Refractory Bricks in Kazakhstan

- Ceramic Fiber Products in Iraq

- Ceramic Fiber Products in Estonia

- Monolithic Refractories in Poland

- Ceramic Fiber Products in Jamaica