All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is iron used in the production of scientific equipment?

Iron is used in the production of scientific equipment due to its various properties such as its strength and ability to withstand high temperatures. It is commonly used in the construction of laboratory equipment, such as beakers, test tubes, and stirring rods, as well as in the manufacturing of precision instruments like microscopes and spectrometers. Additionally, iron is a crucial component in the production of magnetic equipment like electromagnets and NMR machines, which are essential for various scientific research and experiments.

What are the properties of iron that make it suitable for various products?

Iron has several properties that make it suitable for various products. Firstly, it is a strong and durable metal, which makes it suitable for applications that require strength, such as construction materials, machinery, and tools. Secondly, iron is malleable and can be easily shaped into different forms, allowing it to be used for a wide range of products with varying shapes and sizes. Additionally, iron is abundant and relatively low-cost, making it a cost-effective option for manufacturing. Furthermore, iron has good magnetic properties, making it suitable for applications in electromagnets, transformers, and motors. Lastly, iron is also highly resistant to corrosion, especially when alloyed with other elements like chromium, making it suitable for products exposed to harsh environments or corrosive substances, such as pipelines, automotive parts, and kitchen utensils.

How do I prevent my iron from leaving imprints on delicate lace fabric?

To prevent your iron from leaving imprints on delicate lace fabric, you can follow these steps:

1. Adjust the temperature: Set your iron to the lowest heat setting suitable for the fabric type. Delicate lace fabric is prone to scorching, so using a lower temperature will reduce the risk of imprints or damage.

2. Use a pressing cloth: Place a clean, thin cotton or muslin cloth over the lace fabric before ironing. This barrier will protect the lace from direct contact with the iron, preventing imprints or any potential burning.

3. Test on a small area: Before ironing the entire lace fabric, test a small, inconspicuous area with the iron and pressing cloth. This way, you can ensure that the fabric does not react negatively to heat or steam.

4. Iron with care: When ironing, use gentle, smooth motions. Avoid pressing down too hard or leaving the iron in one spot for too long, as this can create imprints or damage the delicate lace.

5. Steam from a distance: If your iron has a steam function, use it cautiously. Hold the iron a few inches away from the fabric and lightly mist the lace with steam. This can help remove wrinkles without directly applying heat to the fabric.

By following these steps, you can minimize the risk of leaving imprints on delicate lace fabric while still achieving a well-pressed appearance.

What is the process of galvanizing iron?

The process of galvanizing iron involves coating the iron with a layer of zinc to protect it from corrosion. This is achieved by first cleaning the iron surface to remove any impurities and preparing it for the zinc coating. The cleaned iron is then immersed in a bath of molten zinc, or it can be coated with zinc using a process called electroplating. The zinc bonds with the iron to form a protective layer, preventing rust and extending the lifespan of the iron.

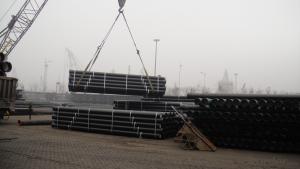

Wholesale Iron Products from supplier in Djibouti

Whether you require iron pipes, iron sheets, iron rods, or any other iron product, we have you covered. Our team of experts will work closely with you to understand your specific requirements and recommend the best products to meet your needs.

In addition to our wide range of iron products, we also offer sales services to ensure a seamless purchasing experience. Our dedicated sales team will assist you in finding the right products at competitive prices, ensuring that you get the best value for your money.

Furthermore, we provide quotations for all our iron products, allowing you to plan your budget effectively. Our team will provide accurate and detailed quotations, including pricing, specifications, and delivery information, to help you make informed decisions.

Additionally, we understand that technical support is crucial for successful project implementation. That's why we offer comprehensive technical support services to assist you throughout the entire project lifecycle. Whether you need assistance with product selection, installation, or troubleshooting, our team of experts is always ready to help.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to provide a high level of service and support to our clients in Djibouti. Our years of experience in the Djibouti market have allowed us to build strong relationships with local suppliers, ensuring that we can deliver quality iron products on time and within budget.

Choose us as your trusted supplier of iron products in Djibouti, and experience the benefits of our comprehensive procurement services. Contact us today to discuss your requirements and let us help you find the perfect iron products for your projects.

In addition to our wide range of iron products, we also offer sales services to ensure a seamless purchasing experience. Our dedicated sales team will assist you in finding the right products at competitive prices, ensuring that you get the best value for your money.

Furthermore, we provide quotations for all our iron products, allowing you to plan your budget effectively. Our team will provide accurate and detailed quotations, including pricing, specifications, and delivery information, to help you make informed decisions.

Additionally, we understand that technical support is crucial for successful project implementation. That's why we offer comprehensive technical support services to assist you throughout the entire project lifecycle. Whether you need assistance with product selection, installation, or troubleshooting, our team of experts is always ready to help.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to provide a high level of service and support to our clients in Djibouti. Our years of experience in the Djibouti market have allowed us to build strong relationships with local suppliers, ensuring that we can deliver quality iron products on time and within budget.

Choose us as your trusted supplier of iron products in Djibouti, and experience the benefits of our comprehensive procurement services. Contact us today to discuss your requirements and let us help you find the perfect iron products for your projects.

Hot Search

- Ductile Iron Pipes in Somalia

- Ductile Iron Pipe Fittings in Liberia

- Ductile Iron Pipes in Montenegro

- Ductile Iron Pipe Fittings in Timor Leste

- Ductile Iron Pipe Fittings in Turkey

- Ductile Iron Pipe Fittings in Cambodia

- Ductile Iron Pipe Fittings in Syria

- Ductile Iron Pipes in Zambia

- Ductile Iron Pipe Fittings in Belarus

- Ductile Iron Pipes in Swaziland