All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

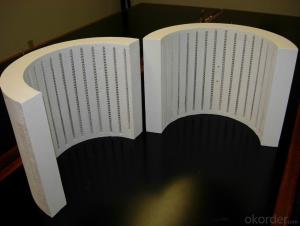

- - Ceramic Fiber Products

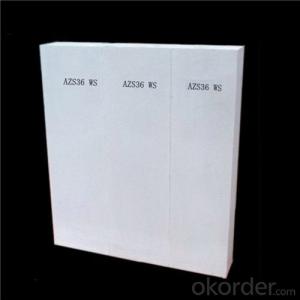

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

How do refractory materials impact the lifespan of industrial equipment?

Refractory materials play a crucial role in extending the lifespan of industrial equipment. These materials are designed to withstand high temperatures, thermal shocks, and corrosive environments, protecting the equipment from damage caused by heat, abrasion, or chemical reactions. By providing a protective barrier, refractory materials prevent the deterioration of equipment components, minimize wear and tear, and enhance overall operational efficiency. Additionally, their high insulation properties help maintain stable temperatures, reducing thermal stress and preventing premature failure. Consequently, the use of refractory materials significantly increases the lifespan of industrial equipment, ensuring prolonged and reliable performance.

What are the refractory materials used in the automotive and aerospace industries?

Refractory materials commonly used in the automotive and aerospace industries include ceramics, such as alumina, silicon carbide, and zirconia, as well as various high-temperature metals and alloys like tungsten, molybdenum, and nickel-based superalloys. These materials possess excellent heat resistance, high melting points, and outstanding mechanical properties, making them suitable for applications requiring extreme temperatures and harsh environments, such as engine components, exhaust systems, rocket nozzles, and thermal protection systems.

What are the different types of refractory cements for corrosion resistance?

There are several different types of refractory cements for corrosion resistance, including alumina-based cements, zirconia-based cements, and silica-based cements. These cements are specifically designed to withstand high temperatures and resist chemical corrosion, making them ideal for applications in industries such as petrochemical, steelmaking, and power generation. Alumina-based cements are known for their excellent resistance to acid corrosion, while zirconia-based cements offer superior resistance to alkali corrosion. Silica-based cements, on the other hand, provide good resistance to both acid and alkali corrosion. Ultimately, the choice of refractory cement depends on the specific corrosive environment and temperature requirements of the application.

How do refractory materials withstand high temperatures?

Refractory materials are able to withstand high temperatures due to their unique properties and composition. They are designed to have a high melting point, low thermal conductivity, and excellent thermal shock resistance. This allows them to resist the effects of extreme heat without losing their structural integrity or physical properties. Additionally, refractory materials often contain additives that enhance their resistance to chemical corrosion and oxidation, further increasing their ability to withstand high temperatures.

Wholesale Refractory Materials from supplier in Poland

Whether you are in need of refractory bricks, castables, mortars, or any other refractory product, we have you covered. Our team of experts is dedicated to understanding your unique needs and providing you with the best solutions. We work closely with our clients to ensure that we offer products that not only meet their technical specifications but also adhere to their budget and timeline.

Our sales team is highly knowledgeable and experienced, providing prompt and efficient assistance with your inquiries and orders. We offer competitive pricing and strive to deliver the best value for your investment. With our strong network of suppliers and partners, we can source and deliver a wide range of refractory materials, ensuring that you have access to the latest and highest-quality products in the market.

In addition to our sales services, we also provide comprehensive technical support. Our team of engineers and technicians is available to assist you with any technical queries, offer guidance on product selection, and provide on-site support if needed. We understand the importance of reliable and efficient refractory materials in various industries, and we are committed to helping you achieve optimal performance and productivity.

At our company, we believe in building long-lasting relationships with our clients. We strive to exceed their expectations by providing exceptional customer service and delivering products of the highest standards. Our commitment to quality, reliability, and innovation sets us apart from the competition, making us the preferred choice for refractory materials in Poland.

Contact us today to discuss your refractory materials requirements, and let us help you find the perfect solutions for your projects.

Our sales team is highly knowledgeable and experienced, providing prompt and efficient assistance with your inquiries and orders. We offer competitive pricing and strive to deliver the best value for your investment. With our strong network of suppliers and partners, we can source and deliver a wide range of refractory materials, ensuring that you have access to the latest and highest-quality products in the market.

In addition to our sales services, we also provide comprehensive technical support. Our team of engineers and technicians is available to assist you with any technical queries, offer guidance on product selection, and provide on-site support if needed. We understand the importance of reliable and efficient refractory materials in various industries, and we are committed to helping you achieve optimal performance and productivity.

At our company, we believe in building long-lasting relationships with our clients. We strive to exceed their expectations by providing exceptional customer service and delivering products of the highest standards. Our commitment to quality, reliability, and innovation sets us apart from the competition, making us the preferred choice for refractory materials in Poland.

Contact us today to discuss your refractory materials requirements, and let us help you find the perfect solutions for your projects.

Hot Search

- Monolithic Refractories in Morocco

- Ceramic Fiber Products in Timor Leste

- Refractory Bricks in Singapore

- Raw Materials For Refractory in Peru

- Monolithic Refractories in Venezuela

- Refractory Bricks in Iceland

- Ceramic Fiber Products in Guinea

- Ceramic Fiber Products in Syria

- Refractory Bricks in Canada

- Refractory Bricks in Angola