All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do you calculate the flow velocity and capacity of steel pipes in hydraulic systems?

To calculate the flow velocity and capacity of steel pipes in hydraulic systems, various factors need to be considered. Firstly, the flow velocity can be determined by using the volumetric flow rate and the cross-sectional area of the pipe. The volumetric flow rate can be calculated by multiplying the velocity of the fluid by the cross-sectional area of the pipe. Secondly, the capacity of the pipe depends on its diameter, length, and the viscosity of the fluid being transported. By considering these factors, along with the pressure drop and the pipe material properties, an accurate calculation of flow velocity and capacity can be achieved.

What is the role of steel pipes in the automotive industry for fuel storage and delivery systems?

Steel pipes are used in the automotive industry for fuel storage and delivery systems to ensure safe and efficient transportation of fuel. These pipes are essential for carrying fuel from the storage tanks to the engine, enabling a continuous flow of fuel and maintaining the required pressure. Steel pipes offer durability, corrosion resistance, and high strength, making them an ideal choice for withstanding the harsh conditions and pressure in the automotive environment. Additionally, steel pipes are also compatible with various types of fuels, making them a reliable and versatile solution for fuel storage and delivery systems in the automotive industry.

What is the impact of water velocity on erosion in steel pipelines?

The impact of water velocity on erosion in steel pipelines is significant. Higher water velocities can cause increased erosion rates in pipelines, leading to material loss and ultimately, pipeline failure. The force of the water flowing at high velocities can wear away the protective coating or lining of the steel pipe, exposing it to corrosion and increasing the likelihood of leaks. Additionally, the turbulence created by fast-moving water can further accelerate the erosion process. Therefore, it is crucial to consider and manage water velocity to mitigate erosion in steel pipelines and ensure their long-term integrity.

Wholesale Steel Pipes from supplier in Poland

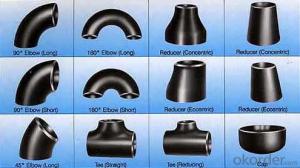

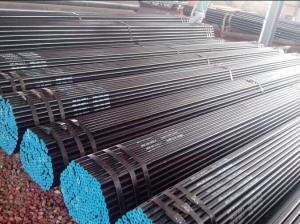

Our team of experts is knowledgeable about the different types of Steel Pipes available in the market and can help you choose the most suitable options for your specific requirements. We have a wide range of products, including seamless steel pipes, welded steel pipes, galvanized steel pipes, and more.

In addition to sales, we also provide quotations for Steel Pipes products, ensuring that you receive competitive prices for your projects. We understand the importance of cost-effectiveness and strive to offer the best value for your investment.

Furthermore, our technical support services are designed to assist you throughout the entire project lifecycle. Whether you need guidance on product selection, installation, or maintenance, our team is here to help. We have a deep understanding of the technical aspects of Steel Pipes and can offer expert advice to ensure the success of your projects.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to provide comprehensive Steel Pipes procurement services in Poland. We have established strong relationships with reputable manufacturers and suppliers, allowing us to source high-quality products at competitive prices.

With years of market development experience in Poland, we have gained valuable insights into the local industry and market trends. We stay up-to-date with the latest developments and regulations, ensuring that we can offer relevant and reliable support for your projects.

If you are looking for a reliable supplier of Steel Pipes in Poland, we are here to meet your needs. Contact us today to discuss your requirements and find out how we can support your projects.

In addition to sales, we also provide quotations for Steel Pipes products, ensuring that you receive competitive prices for your projects. We understand the importance of cost-effectiveness and strive to offer the best value for your investment.

Furthermore, our technical support services are designed to assist you throughout the entire project lifecycle. Whether you need guidance on product selection, installation, or maintenance, our team is here to help. We have a deep understanding of the technical aspects of Steel Pipes and can offer expert advice to ensure the success of your projects.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to provide comprehensive Steel Pipes procurement services in Poland. We have established strong relationships with reputable manufacturers and suppliers, allowing us to source high-quality products at competitive prices.

With years of market development experience in Poland, we have gained valuable insights into the local industry and market trends. We stay up-to-date with the latest developments and regulations, ensuring that we can offer relevant and reliable support for your projects.

If you are looking for a reliable supplier of Steel Pipes in Poland, we are here to meet your needs. Contact us today to discuss your requirements and find out how we can support your projects.