Hot Rolled S45C, C45, S50C Steel Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

S45C / C45 / S50C steel sheets description :

1.Main application

For plastic moulds, cold work die and mould base as well as constructional part

2.Manufacturers

An Steel, Wuyang Steel, Xiang Steel, Liu Steel, Bao Steel, etc.

3.Delivery condition

Hot rolling

Hardness: annealed HB≤210

Diameter: 12~500mm Length:1800~12000mm

4.General

High quality carbon constructional steel

5.Chemical analysis

Grade | C% | Mn% | Si% | P | S |

S45C | 0.42~0.48 | 0.6~0.9 | 0.15~0.35 | ≤0.030 | ≤0.030 |

6.Delivery

Acc. to your request—Standard steel bar(sawing)

——non-standard steel bar(sawing)

or Mill deliver condition,without sawing or cutting

7.Compared grades(based on usage):

Chinese | American | German | Japanese |

| GB | AISI | DIN | JIS |

| 45# | 1045 | 1.1191 | S45C |

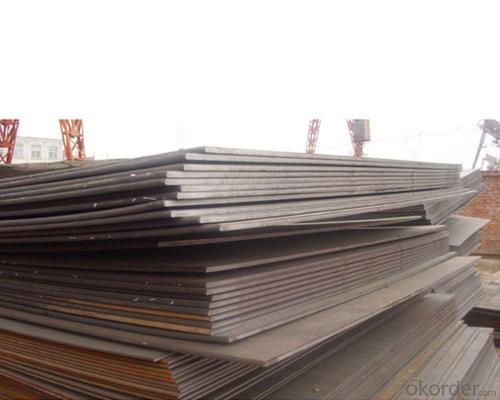

Product show

Workshop show

Shipping

1. FedEx/DHL/UPS/TNT for samples, Door-to-Door;

2. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving;

3. Customers specifying freight forwarders or negotiable shipping methods!

Delivery Time: 3-7 days for samples; 5-25 days for batch goods.

Payment Terms

1.Payment: T/T, L/C, Western Union, MoneyGram,PayPal; 30% deposits; 70% balance before delivery.

2.MOQ: 1pcs

3.Warranty : 3 years

4.Package Informations: 1) EXPORT, In 20 feet (GW 25 ton) or 40 feet Container (GW 25 ton)

2)as customer's requirement

Why choose us?

(1) The leading exporter in China special steel industry.

(2) Large stocks for various sizes, fast delivery date.

(3) Good business relationship with China famous factories.

(4) More than 7 years steel exporting experience.

(5) Good after-sales service guarantee.

- Q: What are the disadvantages of using special steel?

- One disadvantage of using special steel is its higher cost compared to regular steel. Special steel typically requires additional alloying elements and manufacturing processes, making it more expensive to produce. Additionally, special steel may have limited availability and require specialized knowledge and equipment for fabrication and handling.

- Q: How does tool and die steel maintain its hardness and wear resistance?

- Tool and die steel maintains its hardness and wear resistance through a combination of factors. Firstly, it is made from high carbon content steel, which provides inherent hardness. Additionally, it undergoes heat treatment processes such as quenching and tempering, which further enhance its hardness and wear resistance. These processes involve rapid cooling and reheating to precisely controlled temperatures, transforming the steel's microstructure and creating a fine, uniform grain structure. This refined grain structure improves the steel's hardness and resistance to wear, making it suitable for demanding tool and die applications.

- Q: What are the main factors affecting the strength of special steel?

- The main factors affecting the strength of special steel include the composition of the steel, the heat treatment process, and the presence of any impurities or defects in the material. Additionally, the grain size and structure of the steel, as well as the presence of any alloying elements or treatments, can also impact its strength.

- Q: What are the different types of special steel coatings?

- There are several types of special steel coatings, including zinc coatings (galvanization), aluminum coatings (aluminizing), chrome coatings (chromium plating), and ceramic coatings, among others. Each type of coating offers unique benefits and properties, such as corrosion resistance, improved durability, increased hardness, and enhanced heat resistance, depending on the specific application requirements.

- Q: How does special steel contribute to the energy equipment industry?

- Special steel plays a crucial role in the energy equipment industry by providing the necessary strength, durability, and resistance to extreme conditions. The energy equipment industry encompasses various sectors such as oil and gas, renewable energy, power generation, and transmission, all of which rely heavily on special steel for their infrastructure and machinery. In the oil and gas sector, special steel is used in the construction of pipelines, drilling equipment, and storage tanks. The unique properties of special steel, such as high tensile strength, corrosion resistance, and the ability to withstand high pressure and temperature, make it an ideal material for these applications. Special steel also ensures the safety and reliability of oil and gas operations, as it can withstand harsh environments, including corrosive substances and extreme weather conditions. In the renewable energy sector, special steel is used in the manufacturing of wind turbines, solar panels, and hydroelectric power systems. These energy sources require strong and lightweight materials that can withstand constant exposure to nature's elements. Special steel alloys, such as high-strength low-alloy (HSLA) steel and stainless steel, are commonly used to construct the infrastructure of renewable energy systems, ensuring their longevity and efficiency. Furthermore, special steel is essential in power generation and transmission equipment. It is utilized in the manufacturing of gas turbines, steam turbines, and generators. Special steel alloys can endure the high temperatures and pressures generated during power generation processes, ensuring the efficiency and reliability of energy production. Additionally, special steel is used in the transmission infrastructure, including transmission towers and power cables, to support the efficient and safe transfer of electricity over long distances. Overall, special steel contributes significantly to the energy equipment industry by providing the necessary strength, durability, and resistance to extreme conditions. It enables the construction of reliable and efficient infrastructure, ensuring the smooth operation of energy systems, whether in oil and gas, renewable energy, or power generation and transmission.

- Q: How does nitriding improve the wear resistance of special steel?

- Nitriding improves the wear resistance of special steel by introducing nitrogen into the surface of the material, forming a hard layer of iron nitrides. This hard layer increases the surface hardness and reduces the friction between the material and other surfaces, resulting in enhanced resistance to wear and improved performance in high-stress environments.

- Q: How is special steel used in the power generation industry?

- Special steel is used in the power generation industry for various applications such as turbine blades, generator rotors, and boiler components. These steels possess exceptional strength, corrosion resistance, and heat resistance properties, making them suitable for withstanding high temperatures and pressures in power plants. They help improve the efficiency and reliability of power generation equipment, ensuring safe and uninterrupted electricity production.

- Q: How is stainless steel used in the food and beverage industry?

- Stainless steel is widely used in the food and beverage industry due to its excellent properties such as corrosion resistance, durability, and hygienic qualities. It is commonly used for manufacturing food processing equipment like tanks, pipes, and storage containers, as well as kitchen appliances and utensils. The non-reactive nature of stainless steel ensures that it does not impart any unwanted taste or odor to the food or beverage being processed or stored, making it a safe and ideal choice for maintaining product quality and safety standards.

- Q: How does special steel contribute to the magnetic properties of products?

- Special steel contributes to the magnetic properties of products through its unique composition and structure. Special steel, also known as alloy steel, contains specific elements such as nickel, chromium, manganese, and molybdenum, which alter its magnetic behavior. These elements can enhance or suppress the magnetism of the steel, depending on the desired application. For example, when nickel is added to steel, it increases its magnetic permeability, making it more receptive to magnetic fields. This property is particularly useful in applications like transformers, where the steel core needs to efficiently conduct magnetic flux. Similarly, the addition of other magnetic elements like cobalt or iron can also enhance the magnetic properties of special steel. On the other hand, certain elements can reduce or eliminate the magnetic properties of steel. Chromium, for instance, is known for its anti-magnetic characteristics. By adding chromium to steel, it can decrease its magnetic permeability, making it suitable for applications that require non-magnetic qualities, such as medical equipment or electronics. Furthermore, the structure of special steel also plays a crucial role in its magnetic properties. Through various heat treatment processes, the steel's crystalline structure can be manipulated, affecting its magnetization. For instance, by annealing the steel, the crystal grains can be made larger, reducing its magnetization. Conversely, cold working or quenching the steel can lead to a finer grain structure, enhancing its magnetic properties. In summary, special steel contributes to the magnetic properties of products by incorporating specific elements that either enhance or suppress magnetism, depending on the application requirements. Additionally, the steel's structure can be modified through heat treatments, further influencing its magnetization. The ability to tailor the magnetic properties of special steel makes it a valuable material for various industries, including telecommunications, energy, and electronics.

- Q: How is free-cutting steel used in the manufacturing of screws and bolts?

- Free-cutting steel is used in the manufacturing of screws and bolts because of its excellent machinability. It contains additives such as sulfur, lead, or bismuth that improve its ability to be easily and efficiently shaped into the desired form. This type of steel enables manufacturers to produce screws and bolts with intricate threading and precise dimensions, resulting in high-quality and reliable fasteners.

Send your message to us

Hot Rolled S45C, C45, S50C Steel Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords