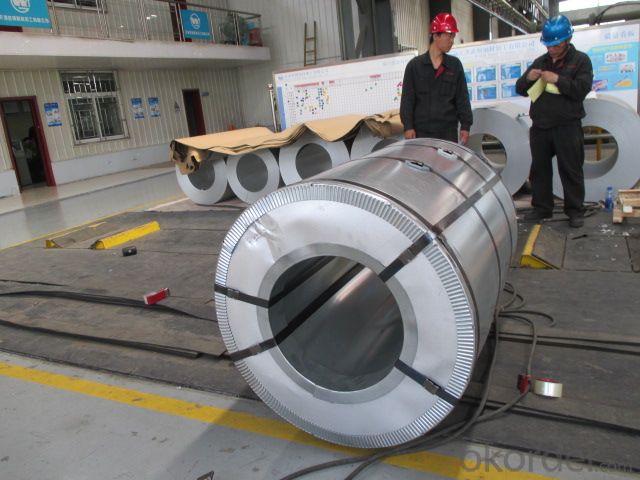

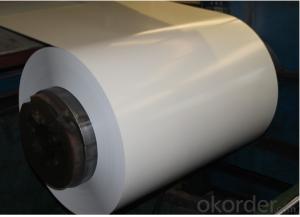

hot Prime PPGI Prepainted galvanized steel coils sheets good price from China for roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Base material: hot dipped galvanized steel coil DX51D

2.Thckness ; 0.16-1.5mm

3.WIdth : 914-1250 mm

4.Zinc : 40-180g

Specification :

1.Thickness : 0.16-1.5 mm

2.Width: 914-1250 mm

3 Zinc coating : 40-180 g

4 coil ID : 508MM/610 MM

Products detailed description:

1> original : China

2> base material : hot dipped galvanized steel coil DX51D

3> coil weight : 3-7 tons

4> T bent test : 1t -3 t

5> pencial hardness : F--H--3H

6> Repercussions impact test : 9 J

7 > Standard : JIS G 3312 ,3302 EN 10146 10169

8> Container standard : 20‘ 40’

9>Delivery detail : within 20-30 days after receving the deposit

10>NEK TEXT : 100 '

11>payment terms : L/C or T/T

12>packing detail :standard sea worthy packing

- Q: Measures to prevent cold rolling of packaged cold rolled steel coils? Who can give some professional opinions oh?

- Cold rolled steel coils are generally sprayed antirust oil, according to user requirements, light, medium, heavy oil 3 types. Nevertheless, if the oil is volatile or in a humid environment, the steel plate comes into contact with the water for a period of time, indicating that it is beginning to rust.

- Q: How are steel coils used in the manufacturing of lighting fixtures?

- Steel coils are used in the manufacturing of lighting fixtures as they provide a sturdy and durable structure for the fixtures. The coils are typically shaped and formed to create the desired shape and design of the lighting fixture, ensuring its strength and stability. Additionally, the steel coils can be coated or painted to enhance the aesthetics of the fixture, making it more visually appealing.

- Q: How are steel coils used in the oil and gas industry?

- Steel coils are used in the oil and gas industry for various purposes such as pipelines, storage tanks, and drilling equipment. These coils are commonly used to manufacture seamless and welded pipes that are essential for transporting oil and gas from production sites to refineries and end-users. Additionally, steel coils are utilized in the construction of storage tanks that store oil and gas in large quantities. They are also an integral part of drilling equipment, including offshore platforms, where they provide structural support and withstand high-pressure environments.

- Q: What are the different types of steel processing equipment for coils?

- There are several types of steel processing equipment used for coils, including slitting lines, cut-to-length lines, blanking lines, and coil-to-coil lines. Slitting lines are used to slit wide steel coils into narrower strips, while cut-to-length lines are used to cut coils into specific lengths. Blanking lines are used to cut shapes out of coils, and coil-to-coil lines are used to transfer coils from one processing stage to another.

- Q: How do steel coil manufacturers ensure employee safety?

- Steel coil manufacturers ensure employee safety through a combination of safety training programs, implementation of safety procedures and protocols, regular equipment maintenance, and providing personal protective equipment. They also conduct regular safety audits and inspections to identify and address any potential hazards in the workplace.

- Q: How are steel coils used in the manufacturing of HVAC ductwork?

- Steel coils are used in the manufacturing of HVAC ductwork as they provide the necessary strength and durability required for the ductwork. These coils are typically processed through a roll-forming machine, which shapes them into the required ductwork profile. The steel coils are then cut to the desired length, welded or joined together, and finally, coated to prevent corrosion and improve the overall performance of the ductwork.

- Q: Can steel coils be stored in a corrosive environment?

- Ideally, steel coils should not be stored in a corrosive environment as exposure to corrosive elements can lead to degradation and damage to the steel surface. Corrosion can weaken the structural integrity of the coils and affect their performance. To ensure the longevity and quality of the steel coils, it is best to store them in a dry and non-corrosive environment.

- Q: How are steel coils used in the manufacturing of automotive fenders?

- Steel coils are used in the manufacturing of automotive fenders by being processed and shaped into the desired fender shape. The coils are first uncoiled and then sent through a series of machines that cut and shape the steel into the specific dimensions and contours required for the fender design. These shaped steel pieces are then welded or bolted together to form the final fender structure, which is later painted and installed onto the vehicle.

- Q: Hey I just got a mini 14 manufactured in 1980. I also had some .223 Wolf steel cased HP rounds (about 200) that i could shoot throught it, but I was just wondering if its a bad idea to use this steel cased ammo...? Only the casing is steel i believe... and the bullet is copper jacketedthanks for your help

- I have used wolf steel cased ammunition as well when I borrowed my friend's AR-15. It's good ammunition and I personally have not experienced a stovepipe or a jam with the ammunition. A Mini 14 is a great .223 civilian rifle made by Ruger and should not jam with the ammunition. If the polymer coating really is a problem sometimes, just don't use it with knockoff AR-15s or Mini-14s but stick with the major manufacturers.

- Q: Steel is strong in both tension and compression. Concrete is only strong in compression, and is very fragile in tension. Plus, concrete is heavy--a huge drawback in, say, a bridge deck. And its fairly expensive. And it hides the condition of the steel embedded within it. So what does it bring to the table? Why use it at all?

- Exposed steel requires constant maintenance including inspection and repainting. Steel does not provide a durable driving surface nor a good friction one for stopping unless it is textured, which makes driving on it very noisy. It is not possible to refinish a steel surface as is a concrete surface which can be ground and had several inches of new wear surface in concrete or asphalt added to it. Concrete is much less expensive than steel and the enclosure of steel inside the concrete protects it like a paint job does. Steel is weakened by heat, as was shown by the 9/11 collapses when the applied fire insulation was blasted off the trusses by the crashes, so a burning truck on or under a bridge may damage concrete but leave it standing strong enough to continue handling traffic during repairs, as at overpasses here in Texas where oil tankers crashed and burned.

Send your message to us

hot Prime PPGI Prepainted galvanized steel coils sheets good price from China for roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords