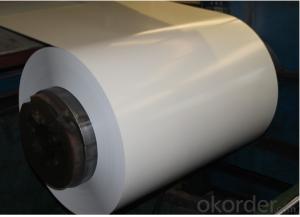

Prime PPGI Prepainted galvanized steel coils sheets good price from China for roofing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prepainted GI steel coil / PPGI / PPGL color coated galvanized steel sheet in coil

Specificaton

Thickness | 0.15mm-3.5mm |

Thickness tolerance | ±0.02mm |

Width | 600--1500mm all available |

Width tolerance | ±2mm |

Length | 1000-6000mm or as to client require |

Zinc coating | 40g/m2-275g/m2 |

Types | Commercial / Drawing / Deep Drawing / Structural quality |

Quality | Soft or hard quality |

Standard | ASTM, AISI, DIN, GB,JIS |

Material | SGCC, DX51D,DX52D, DX53D,SGCD , Q195, Q235, SGHC, DX54D, S350GD, S450GD, S550GD, etc |

Spangle State | Regular spangle, small spangle, big spangle, non-spangle |

Surface treatment | chromed / oiled/slightly oiled/ dry/ anti-fingerprint etc |

Coil weight | 3-8ton or as client requirement. |

Coil ID: | 508 /610mm |

Packing | Export standard. |

Min order | 50 tons |

Mechanical Properties | |||

Grade | Yield Strength MPa | Tensile Strength MPa | Elongation % |

SGCC(DX51D+AZ) | ≥205 | ≥270 | ≥22 |

SGCD(DX52D+AZ) | ≥140 | ≥270 | ≥38 |

S250GD+AZ | ≥250 | ≥330 | ≥19 |

S350GD+AZ | ≥350 | ≥420 | ≥16 |

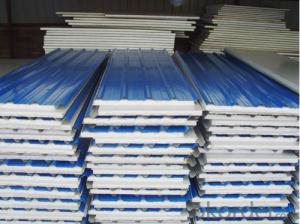

Aplications

1.Refrigerator shutter &side panels,

2.household appliances,Washer,Freezers

3.Computer/ DVD/DVB Panels , etc.

- Q: What is the minimum thickness of a steel coil?

- The minimum thickness of a steel coil can vary depending on the specific grade and type of steel being used, as well as the manufacturing process. However, generally speaking, the minimum thickness of a steel coil is typically around 0.001 inches (0.0254 millimeters). It is important to note that this value is a general guideline and can vary based on the specific requirements and standards set by the industry or application.

- Q: What are the different types of steel coil coatings?

- Various purposes require the use of different types of steel coil coatings. Some of the most commonly used types include: 1. Galvanized Coating: This coating, based on zinc, offers excellent corrosion resistance to steel coils. It is often utilized in outdoor applications that subject the coils to harsh weather conditions. 2. Galvannealed Coating: Similar to galvanized coating, galvannealed coating also contains zinc, but it undergoes heat treatment to form an alloy with the steel surface. This type of coating provides superior paint adhesion and is frequently employed in applications where the coated coils will be painted or further processed. 3. Pre-painted Coating: As the name suggests, pre-painted coatings are applied to steel coils before they are delivered to customers. These coatings can be made of various materials such as polyester, polyurethane, epoxy, or fluoropolymer. Pre-painted coils are commonly used in the construction, automotive, and appliance industries. 4. Electro-galvanized Coating: This coating is applied to steel coils through an electroplating process, depositing a thin layer of zinc on the steel surface. Electro-galvanized coatings offer good corrosion resistance and are often employed in indoor applications or where a thinner coating is desired. 5. Aluminized Coating: Aluminized coatings involve applying a thin layer of aluminum to the surface of steel coils. This type of coating provides excellent heat resistance and is commonly used in exhaust systems, ovens, and other high-temperature applications. 6. Organic Coatings: Steel coils are typically coated with organic materials to provide additional protection against corrosion and improve aesthetics. These coatings can come in the form of paints, lacquers, or powder coatings, and they can be tailored to meet specific requirements in terms of color, gloss, and durability. In conclusion, the selection of a steel coil coating depends on the specific application, environmental conditions, desired aesthetics, and performance requirements.

- Q: What are the challenges in coil blanking?

- In order to achieve efficient and accurate production, coil blanking, a process used to cut flat metal sheets from coiled stock, must tackle several challenges. Some of the key challenges include: 1. Material variations: Coiled stock can have variations in thickness, width, and surface quality, which can impact the cutting process and result in inconsistent blanks. To ensure consistent quality and dimensional accuracy, it is crucial to carefully select and control the material. 2. Coil set and crossbow: Coiled stock often has inherent shape imperfections like coil set (longitudinal curvature) and crossbow (transverse curvature), which can cause alignment issues during cutting. Minimizing these imperfections requires the use of specialized equipment and techniques, such as straighteners and leveling systems. 3. Coil edge condition: The edges of coiled stock can have burrs, waves, or irregularities, which can affect the quality and precision of the cut blanks. Employing proper edge conditioning techniques, like deburring or edge trimming, is necessary to ensure clean and straight edges. 4. Slitting and shearing forces: The forces exerted during coil blanking can induce stresses and strains in the material, potentially leading to deformation or springback. To minimize these effects and maintain dimensional accuracy, careful consideration of slitting and shearing forces, along with proper tooling design and machine settings, is necessary. 5. Scrap and material waste: Coil blanking can generate significant amounts of scrap material, especially during setup and adjustment phases. Managing scrap and reducing material waste is crucial to optimize production efficiency and minimize costs. Efficient nesting algorithms and real-time monitoring systems can help achieve this. 6. Automation and productivity: Due to market demands, coil blanking often requires high-speed and high-volume production. Enhancing productivity can be achieved through the implementation of automation systems, such as robotic material handling and advanced control systems. However, integrating and synchronizing these components with the cutting process requires careful planning and system integration expertise. Overall, addressing these challenges in coil blanking necessitates proper material selection, advanced equipment, specialized techniques, and efficient process control. By overcoming these challenges, manufacturers can achieve consistent quality, dimensional accuracy, and productivity in coil blanking operations.

- Q: Can steel coils be painted?

- Yes, steel coils can be painted. Painting steel coils is a common practice to enhance their appearance, protect them from corrosion, and provide additional durability. The coils are typically cleaned, prepped, and coated with a primer before applying the desired paint color.

- Q: What are the advantages of using hot-rolled steel coils?

- Hot-rolled steel coils offer several advantages, including improved strength, durability, and formability. The high temperature during the rolling process allows for better shaping and molding, making it suitable for various applications. Additionally, hot-rolled steel coils have a smoother surface finish and are more cost-effective compared to cold-rolled steel coils.

- Q: My company want to welding stainless steel, do not know to use what welding machine?

- They actually make a stainless rod now that can be used with most arc welders

- Q: If I wear a pair of thick wool socks, is walking around in the snow with steel-toed boots going to be a problem? I'm wondering if the steel will make my toes too cold.

- Dr. Martens makes a number of pairs of steel toed work boots. I have never owned a pair of their steel toes, but I have owned several pairs of their shoes and boots, the oldest of which is fifteen years old and still going strong. They take a couple of weeks to break in, but once they do, they are practically molded to your foot. They are more expensive, but they last a LONG time. Good Luck!

- Q: What are the different methods of storing steel coils?

- There are several different methods of storing steel coils, including vertical stacking, horizontal stacking, eye-to-the-sky stacking, and interlocking stacking. Each method has its own advantages and considerations based on factors such as space availability, weight distribution, and accessibility for transportation and handling. Ultimately, the choice of storage method depends on the specific requirements and constraints of the steel coil storage facility.

- Q: Are steel coils susceptible to damage during storage or transportation?

- Yes, steel coils are susceptible to damage during storage or transportation. Steel coils are often heavy and can be prone to deformation, bending, and scratching if mishandled. Additionally, improper stacking or securing during transportation can lead to shifting or movement of the coils, which can cause damage. Furthermore, exposure to moisture, extreme temperatures, or corrosive substances can also affect the integrity of the steel coils. Therefore, it is crucial to handle, store, and transport steel coils carefully to minimize the risk of damage and ensure their quality and usability.

- Q: How are steel coils used in the production of metal doors and windows?

- Steel coils are used in the production of metal doors and windows as they are the primary raw material. The coils are processed through various manufacturing techniques such as cutting, bending, and shaping to create the frames and panels of the doors and windows. The steel coils provide strength, durability, and structural integrity to the final products, ensuring long-lasting and secure doors and windows.

Send your message to us

Prime PPGI Prepainted galvanized steel coils sheets good price from China for roofing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords