hot Prime PPGI Prepainted galvanized steel coils sheets good price for roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

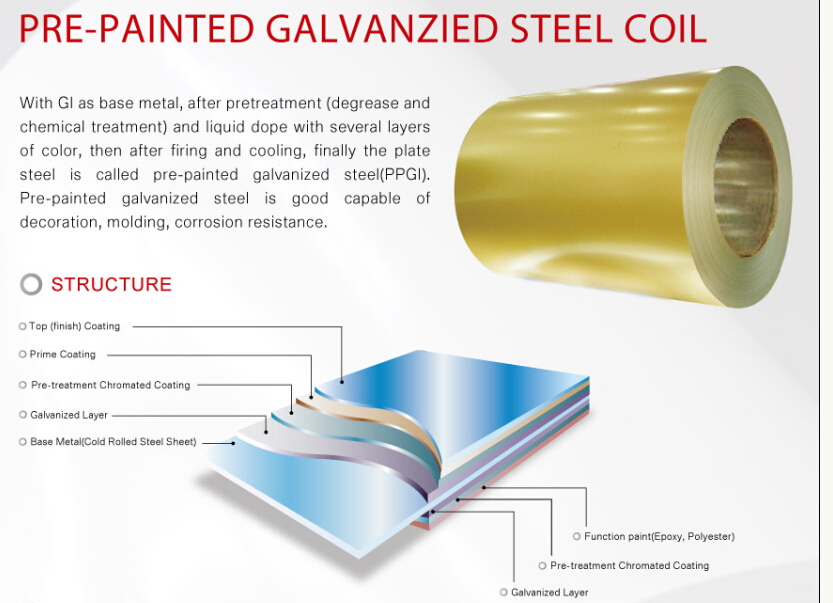

Prepainted galvanized color coated PPGI steel:

| Thickness | 0.12-1.2mm |

| Width: | 700-1250mm |

| Material: | SGCC,SGCD,SECC,SECD,DX51D+Z |

| Zinc coating: | 30-180G/M2 |

| Surface Structure: | galvanized ,zero spangle, regular spangle or normal spangle |

| COLOR: | RAL number or sample colour |

| Coating: | Topside: 5micron primer +15-20microns polyester Backside: 5-8microns primer epoxy. Surface treatment: chromated and oiled, chromated and non-oiled |

II Main characteristics :

1.strong corrosion resistance

2.surface quality

3.conducive to deep processing,such as corrugated steel sheet 4.economy and practicality

III Applications:

Household Appliance:

1.Refrigerator shutter &side panels, Washer, Freezers, Air conditions,

2.Rice Cooker, Microwave Ovens, Water Heaters, Sterilization Cabinets, Range Hoods

3.Computer Panels , DVD/DVB panels, TV back panel etc.

Advantages of Our Prepainted Galvanized SteelCoil:

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

- Q: What are the different coil leveling machine configurations used for steel coils?

- There are several different coil leveling machine configurations used for steel coils, depending on the specific requirements of the application. Some common configurations include single-leveler machines, which use a set of leveling rollers to reduce the coil's thickness variations; double-leveler machines, which employ two sets of leveling rollers for enhanced precision; and stretch leveling machines, which utilize a combination of roller leveling and tension to remove coil shape defects. These configurations can be further customized with additional features such as coil feeders, crop shears, or edge trimmers, depending on the desired end product and production requirements.

- Q: looking to buy a sashimi knife. what is the difference between white steel (1and2) and blue steel (1and2) in terms on characteristics. what gets sharper? what holds edge longer? basically any info on the pros and cons of each steel would be SO GREATLY APPRECIATED! thanks in advance to all who answer. i'm leaning towards white-2 steel for my first sashimi knife, started training on the sushi bar and need a new tool!

- Blue Steel Knife

- Q: Describe and explain how the differences in the properties of the thee main types of steel allow them to be used in different ways. I have some chemistry homework due in for tomorrow (yes I know i left it a bit late but I really don't like chemistry) and I would love it if I could actually at least pretend to my teacher that I know what she's on about this lesson because honestly, I really don't know what she spends so long telling us all. Any help would be appreciated and points for the best answer!

- Steel is basically Iron with Carbon! The higher the % of Carbon, the stronger the steel, but the less tensile (Bendy) strength it will have!

- Q: I'm doing a commercial for chemistry and I need to know any kind of chemistry dealing with Callaway Big Bertha Irons. I know they are stainless steel but any more info would help out! Thank you! :)

- Stainless steel is a mixture of metals, each metal is included in order to make up for each others weaknesses. Each metal is included due to a property that is benificial in some way, for instance Chromium is included because it makes the stainless steel 'stainless'. In chemistry a mixture of metals, stainless steel, is called an alloy.

- Q: How do steel coil manufacturers ensure timely delivery?

- Steel coil manufacturers ensure timely delivery through various strategies and measures. First and foremost, they maintain a well-coordinated production and supply chain management system. This includes efficient scheduling of production processes, monitoring of inventory levels, and close coordination with suppliers of raw materials. Additionally, steel coil manufacturers often employ advanced forecasting techniques to predict the demand for their products. By analyzing historical data, market trends, and customer behavior, they can anticipate future orders and plan their production accordingly. This proactive approach minimizes the risk of delays and allows for better resource allocation. Furthermore, manufacturers work closely with transportation and logistics companies to ensure smooth and timely delivery. They establish strategic partnerships and negotiate favorable agreements to facilitate efficient transportation of steel coils to customers. This includes optimizing routes, utilizing reliable carriers, and closely tracking shipments to promptly address any unforeseen issues. Moreover, manufacturers may maintain buffer stocks to mitigate the impact of unexpected disruptions, such as equipment failures or supplier delays. By having a safety stock of finished products, they can quickly respond to urgent orders and maintain their delivery commitments. Lastly, effective communication plays a crucial role in ensuring timely delivery. Steel coil manufacturers maintain open lines of communication with their customers, keeping them informed about production progress and potential delays. This transparency allows for proactive problem-solving and helps in managing customer expectations. In conclusion, steel coil manufacturers ensure timely delivery by maintaining efficient production and supply chain management systems, utilizing advanced forecasting techniques, collaborating with transportation and logistics companies, maintaining buffer stocks, and maintaining effective communication with customers. These strategies collectively enable them to meet delivery deadlines and provide reliable service to their customers.

- Q: Hello... I'd like to know where I can find proof of this answer as well please. My own searching didn't come up with anything concrete.I'd like to know how much the ambient temperature inside of a hollow steel tube would rise by if the outside of that tube was exposed to an 1100 degree flame for a period of 3 seconds.If specifics help, they are something along the lines of 3.125 O.D. tube, 0.35 wall thickness. High grade steel, can't be more specific than that sorry.Thanks for any answers!

- I can asnswer this from practical experience. If the tube is sealed, temperature would rise approx. 25 deg F. If the tube were open the temperature would be less that a 10 deg F rise. The exact answer can be found in any book on thermodynamics.

- Q: I do a lot of scrapping and would like to be able to separate stainless steel from regular steel. The magnet test doesn't always work since stainless can be magnetic, but what are some ways that I can for sure tell the difference? Or even something like a sound that they make that may help me to tell the difference.

- Stainless steel should be non-magnetic.

- Q: We are going to build a house with a steel frame.Someone told me today that these houses have problems with humidity.Is that true?Please tell me all you know..

- That's a first for me. The only draw back to a steel frame home is the cost, not only in material but also in labor. They do make a great home with proper installation. Make sure your contractor and framing crew have experience with metal frame construction. There is some differences in building codes, etc. Good Luck and happy building.

- Q: How are steel coils used in the production of elevator components?

- Steel coils are used in the production of elevator components to manufacture various structural and mechanical parts. These coils are typically formed, shaped, and cut to create components such as elevator guide rails, brackets, frames, and support structures. The high strength and durability of steel make it an ideal material for these components, ensuring the safety and reliability of elevators.

- Q: How are steel coils used in the production of storage tanks and silos?

- Steel coils are used in the production of storage tanks and silos as they provide the necessary structural strength and durability required for these storage structures. The coils are formed, cut, and welded into the desired shape to create the walls and roofs of the tanks and silos. This ensures that the storage vessels can withstand the weight of the stored materials and any external forces exerted on them.

Send your message to us

hot Prime PPGI Prepainted galvanized steel coils sheets good price for roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords