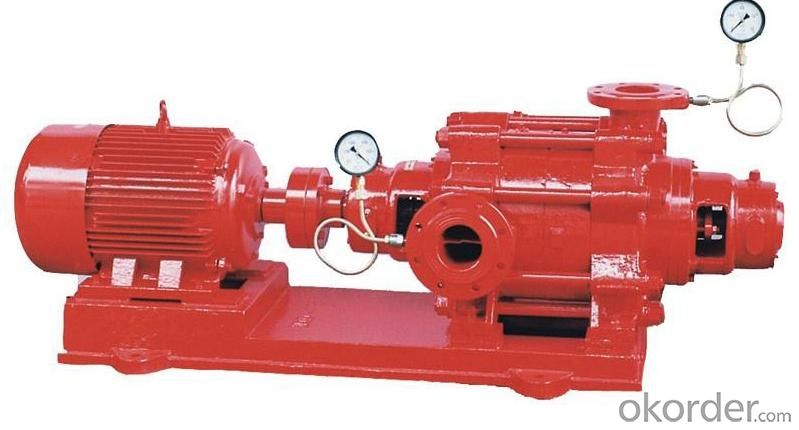

Horizontal Multi-stage Fire Fighting Pumping Unit

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

multi-stage fire fighting pumping unit

Advantages

1.Directly coupled, vibration proof and low noise.

2.Same diameter of inlet and outlet .

3.C&U bearing ,which is the most famous brand in China.

4.Circulating flow cooling ensure mechnical seal long life .

5.Small foundation required that will saving construction investment by 40-60%.

6.Excellent seal that is no leakage

Application

Apply as the transportation of liquids in the fields of air condition, heating, sanitary water, water treatment cooling, refrigerating system, liquid circulation, water supply, pressure boosting,sea water delivery and irrigation etc.

Working Conditions

Rotating speed: 3600r/min, 1800r/min, 2960r/min, 1480r/min

Medium: clean water or other liquids similar to clean water in physical and chemical properties

Medium temperature: -10 ~ 80°C,400°C available under special design

Ambient temperature: Up to 40°C

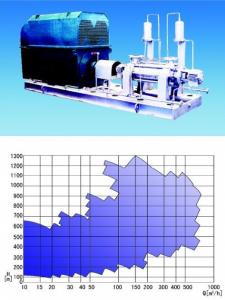

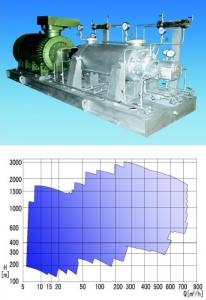

Range of capacity:1.8~2000m3/h

Range of head: up to230m

Maximum working pressure: suction pressure+head of pump≤25 bar

Pump Construction

Casing/impeller:cast iron,stainless steel,copper,bronze

Shaft:carbon steel 45#,stainless steel

Mechnical seal:graphite/silicon carbide/tungsten carbide

Structure Description

Compact structure, most application for modern constructions.

1.Pump casing: the spiral casing with pipe connection is designed and manufactured by the most superior bydraulic model nowadays, with inlet and outlet the same diameter. Flanges conform to GB4216.5, and are equipped with Rp1/4 or Rp 3/8 pressure testing plug.

2.Impeller: closed impeller ,no limit to rotation direction under the water temperature below 80°C and 120°C.

3.Special design of dynamic seal ring ensure well seal and reliable operation..

Motor

TEFC air-cooled squirrel cage, 3 phase asynchronous motor.

Voltage: 220V,380V,400V,415V,440V,660V(other voltage ,pls inform before order)

Frequency: 50Hz,60Hz

Insulation : IP44/IP54/IP55

Protection class: B/F

Insulation modes: B35

- Q: If I were to go to a shop, how much would it cost to replace my water pump? It's a 4.0 6 cyl engine.

- $70-$150 +cost of pump. Most shops have certain maintenance hours for certain jobs. Call around for exact pricing. Honestly, if you have a sockets (metric) and wrenches you can do it yourself in about an hour or two, maybe less. You don't have to mechanically inclind to replace the water pump on the 97 Wrangler. If you do it, I do recommend buying a Haynes/Chilton's book if you don't really have a clue. If you need to buy the tools, book, pump (gasket should come with it), water pump RTV, and coolant. That will still be a lot cheaper than paying somebody. Plus, you will get the joy of doing it yourself. Also, you could put the savings into a high-flow pump, vice original equipment.

- Q: I was wonder if there is a water pump in the out drive, my boat is overheating we are think it could have something to do with the water pump

- So far the only other answer is dead wrong. Your Bayliner has a raw water pump mounted inside the boat. Depending on HP it might be on the front of the crankshaft, or opposite the alternator on the AQ120-140 motors. Then there is a second water pump, which circulates the water through the block. There is no 3rd water pump. None of the Volvo engines have a water pump in the stern drive. I repeat none! The Raw water pump is a rubber impeller. The Thermostat can also be blocked and cause overheating. In some cases it's actually rust/crud that block the exhaust elbows which in turn blocks flow. If you run it on a flush attachment you might be able to check blockages by the amount of water exhausted from the transom/drive. You can edit your question with your specific engine. It takes 7 to 10 min to replace the water pump impeller. You do not have to prime the water pump....ever. Do not however run with out water. Either being in the lake,Bay. ocean, or using the correct flush attachment.

- Q: My mechanic doesn't get back in town until next week, and I'm struggling without my car. I don't really have any other options mechanic wise and I'm not dropping $1000 like meineke wants.How easy is it to follow the Haynes repair manuals or any other repair manuals? I have a 1996 dodge avenger and I need to replace my water pump. I know it's a time consuming task, but is it especially hard to replace it?

- Try another repair shop. I had my water pump replaced for about $300 and that included the pump and labor and a belt ... Meineke is pricey. You can do better pricewise... Ask around... neighbors... people at work... My water pump was under something else that also had to be taken ou to get to it... not a job I'd want to tackle.

- Q: Does anyone know where to find small A/C powered submersible pumps, that operate at 20-25 psi? I can only find D/C pumps for ship use.I need one for running humidifiers and misters for large terrariums

- Gonna need more info for this one, start with the usage requirements for the equipment you are supplying. That should give you something to talk about with the local sources. The size of the terrariums and the amount of water in each one, the height that you want to lift the water is another factor to be considered. Be sure to include the diameter of tubing to be used and any special features, fountains, misters, etc. Good Luck

- Q: I have a 1997 Honda Civic DX and i recently took it in to have its timing belt and water pump replaced. Since then, I have noticed a change in the cars performance. I have lost both gas mileage and power since i took my car in. The maintenance supposedly took the dealer twelve hours to complete which seemed a little odd to me. Do you think this is linked? I just remember getting a lot more miles to a tank of gas, and my car was about the same speed as a friend of mine's who now smokes me. Thank You.

- 12 hours on a civic DX. I am a honda mechanic and I will say that this job only takes 2 hours, 4 hours if your slow and never done it before. Mind you this includes timing belt, water pump, cam seal, crankshaft seal, serpentine belts, valve cover gasket, spark plugs if needed, Honda coolant, and valve adjustment. If you are 1 tooth off on timing your Honda will run, but it will run very rough. Sounds to me like they may have the timing 1 tooth off, 2 teeth off and the car just wont run and if it does it will barely run. This car needs to be taken back and everything i told you should have been done and done properly. What probably happened is the dealer let an apprentice work on the car, since this civic is the easiest to do a timing belt on. However its still their fault that it was not done properly.

- Q: Why is the water pump usually used multi-stage pumps, while the circulating pump is usually a single-stage pump?

- The circulating pump is usually used in the closed-loop system, circulating pump will be generated when the pump pressure, the pressure is also said, and the suction pump up is in normal pressure system, the outlet of the closed-loop system, when the system pressure is 0.1MPa, the water pump for water system needs higher than 0.1MPa, the difference of pressure difference the greater the water faster, on the contrary, the smaller the slower the pressure difference; so the normal work must want water pump outlet pressure is greater than the system pressure. The replenishment pump is usually multi-stage pumps, and circulating pumps are usually single pump is wrong, as long as the replenishment pressure difference to meet the requirements, multi-stage pumps and single-stage pumps are not affected.(single stage pump and multi-stage pump difference: 1, single-stage pump water level "is a wheel is a level", an impeller, no other brothers and sisters for help; and a plurality of multi-stage pump impeller, there are brothers and sisters for its help, so that his ability to work is high. Just as a man works alone and a lot of people work together, the work is differentTherefore, as long as the design requirements are met, it is not important to select multi-stage pumps and single-stage pumps.

- Q: Our watrer pump on our well will constantly prime itself when we use the water in our house.As you are running the tap the water will gain pressure on and off like someone is using another tap in the house. Any suggestions?THanks in advacne

- How old is the Pump ? Could the Impeller be worn out ? Is there a replaceable filter ? Could it possibly be stopped up ? Are there any leaks in the pipe leading from the well ? Is there a way that you could measure the current being drawn by the pump, with an Amp Meter, to determine if it's pulling more Current than it should be ? Until these questions are answered, it's probably just going to be a guessing game.

- Q: A rectangular tank that is 2 feet long, 3 feet wide and 6 feet deep is filled with a heavy liquid that weighs 80 pounds per cubic foot. How much work is done pumping all of the liquid out over the top of the tank?How much work is done pumping all of the liquid out of a spout 5 feet above the top of the tank?How much work is done pumping two-thirds of the liquid out over the top of the tank?How much work is done pumping two-thirds of the liquid out of a spout 5 feet above the top of the tank?I thought that math was hard enough and now they added physics..

- Work is force x distance, which is conveniently pounds x feet. Since we are only interested in the height here (as that is the direction we are pumping), we only need to integrate along that path. The differential weight/force being pumped is the volume (LxWxH = 2 x 3 x dH) times the density (80) and the distance is the height that volume is pumped (6 - H). So W = integral( 6 * 80 * dH * (6-H)) from H=0 to 6 W = integral ((2880 - 480H) dH) = 2880H - 240*H^2 = 2880(6) - 240*(6)^2 = 8640 foot-pounds of work. If you are pumping from the spout, replace the 6-H with 11-H, and the answer becomes 23,040 foot-pounds, which makes sense since you have almost tripled the averge height you were lifting. For the 2/3, change the range of the integration to H = 2 - 6, since H = 0 - 2 represents the water at the bottom of the tank that will still be there later. This gives you answers of 3840 and 13,440 foot-pounds respectively, showing that the last couple of feet are the hardest to pump out (because they have the farthest to go...)

- Q: i am not sure whether the water pump is bad or how much water should come out of exhaust.

- take it in.

- Q: i want to change the water pump on my on a 70 hp (70C) nissan outboard motor and i never pulled a lower unit, not sure what to expect thanks for any help

- hi you need to get the workshop manual for your motor. You can go to the library I am sure they will have one. The basics though... make sure you have a lower unit gaskey set, a full water pump rebuild kit and the correct impellor. You need the manual so that you can locate the correct bolts to loosen and the procedure for disconecting the gear shifting mechanism. With the manual its an easy job. without.. its kind of pot luck if you have never done it before. I have changed impellors and water pumps on many different boat motors and i have aways used the manuals. Even now I would still use the manual as a reference to change the impellor and water pump housing in my Johnson even though i have done it before. The manual will probily cost about $25 but it will save you hundreds in the long run as you will be able to trouble shoot other problems.

Send your message to us

Horizontal Multi-stage Fire Fighting Pumping Unit

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords