HN Series Canned Motor Pump with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

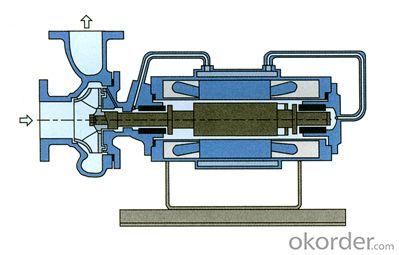

Production Overview of HN Series Canned Motor Pump

The canned motor pump body connects directly with motor front flange, and can convey the medium low temperature fluid with no granule be zero leakage.

The Canned Pump is a centrifugal pump, close coupled to a Canned Motor in such a way that

there is no dynamic shaft seal, no couplings and no ball bearings. The motor is cooled by the

pumped liquid and the sleeve type.

Bearings are lubricated by the same liquid. This eliminates the need for external lubrication.

The stator of the driving motor, which is usually three phase squirrel cage induction motor,

which is hermetically contained in a stator containment that consist of an external frame tube,

out board & inboard end plates and the internal cylinder liner. The rotor which is welded on

the shaft, is also encapsulated with a non magnetic liner. Both stator liner (Stator Can) and

rotor liner (rotor can) are seal welded at both ends, and does not allow any part of the motor to be

exposed to external environment or internal pumped liquid.

Featurers of HN Series Canned Motor Pump

1) No shaft seals, no leak paths

2) No buffer pots to maintain

3) No coupling or alignment problems

4) Primary leak containment shell

5) Proven bearing monitor detects bearing wear before primary leak containment shell is contacted by the rotor

6) Dry stator design and sealed junction box terminal plate

7) Controlled bearing enviroment, conservation bearing design and hydraulic thrust balancing,extended bearing life

FAQ

Q: How can I get trained on CNBM products?

A: Yes, we provide training courses in our factory (products, general and specific pump technology, hydraulics, and practical applications). Please consult your sales manager or get in touch with our headquarters for more information.

Q: Are your pumps cheaper than those of your competitors?

A: CNBM aims to give its customers the highest standards of quality and service and delivery times, all at a reasonable price.

Q: Do you have self-priming pumps?

A: Yes, our product portfolio also includes two ranges of self-priming pumps: self-priming electric pumps and self-priming side channel pumps.

Q: Is it really necessary to fit a bleed valve for the boxes?

A: It is always best to have a bleed valve as the gas produced by the fermenting sewage is potentially hazardous.

Q: If I increase the power of the motor, must I also increase the power of the inverter?

A: You must select the size of converter that allows maximum absorption of the electric motor.

Q: Do you have pumps with grinders?

A: Yes, the WQ models.

- Q: Ok, so if i have an 80 watt solar panel and want to run a 12v dc fan and water pump ONLY when the sun is out or enough light to power them, will i need something like a voltage regulator? I would like to have the panels charge deep cycle 12 v batteries at the same time or when the fan and pump is not running. For instance, i have the panels out and my fan and pump on allowing them to run only on solar as well as charge the batteries. What diagram would i use? I would probably get a charge control for the batteries but more importantly what would i need to regulate the power from the panels? Inverter?

- You may have to do some math. The 80 watt panel is only 80 watts at peak sun on a 75°F day at the equator. Chances are you will have something less than 80 watts to work with. But you can add up all the hours of partial sun to get an equivalant number of peak sun hours. An example would be a few hours in the morning and evening at partial power and a couple of hours at solar noon at nearly full power may give you 5 peak sun hours worth of light. 5 psh x 80 w/ps = 400 wh Your supply may have 400 watt hours worth of power per day. You state that the fan is 12v dc but what is the wattage? It could be a little 12v dc fan out of a computer or it could be a huge 12v dc fan out of an RV. What is the power requirements of the water pump? Is it a little 12v dc one for a foot tall decorative fountain or an industial 3 phase pump for a well? To charge the battery you need a voltage 120% higher than the battery voltage. 12v x120%=14.4 v To add up your loads convert them all the use to dc watt hours per day Here is an example to give you an idea of how to play with your numbers: Fan 12vdc x 1.5 A = 18 watts, use this for 5 hours your load would be 18w x 5hr = 90 watt hours Pump 120 vac x 2.5 amps = 300 watts (The AC will need to come from an inverter. The inverter has a certain amount of loss. How good it does the job of converting dc to ac is know as it's efficency. Lets use 90% to be safe) 300 watts / 0.90 = 333.4 watts, use this for 1/2 hour per day 333.4w x 0.5hr = 166.7 watt hours The 90 watt hours + the 167 watt hours = 257 watt hours per day. This would leave about 140 watt hours to put into the battery. Yes it would be best to use a charge controller to protect the battery from overcharging if the pump and fan are off, or from draining the battery too much if the fan or pump stays on.

- Q: I have a water leak, and not from the radiator. It is on the side of the motor where the timing belt is. Could it be the water pump? or possibly freeze plugs? If so where are these?

- most likely the water pump. The water pump is under the timing cover and is driven by the water pump. Make sure that you replace the timing belt when you replace the pump.

- Q: Water pump "rated lift: 6m" what do you mean?

- Lift refers to the weight of fluid per unit weight after the pump, the pump is an important working parameter, also known as pressure head. Simply stated: rated lift 6M refers to the rated operating conditions of the pump, the increase of energy 6M water column height. Here's an example to help you understand:Example 2-1 the head of a centrifugal pump is now measured. The refrigerant is 20 DEG C water, the measured flow rate is 60m^3/h, vacuum pump inlet meter 0.02Mpa, outlet pressure gauge readings for the 0.47Mpa (g), the two known table between the vertical distance is 0.45M if the suction pipe of same diameter and pipe pressure pump, calculate the pump head.Solution:Check the water density at 20 centigrade 1.0*10e3kg/m3,H=0.45m (1Mpa approximately equal to 100 m water column)P exports =0.47Mpa (0.47*100 m water column, =47 m water column)P imports =-0.02Mpa (0.02*100 m water column, =2 m water column)P is the density of the liquidH=h+ (P -p / P g=0.45+ export import) (0.47*10e6- (-0.02*10e6)) / (10e3*9.887) =50.5m (water)

- Q: Water pump located on the ground floor of our 10 story building is leaking and therefore it is constantly running and spilling water into the parking lot. Therefore, a plumber shut the water pump off and opened a bypass valve.After we shut off water pump all units still have good water pressure so why do we need to replace water pump?When water pump is on the incoming city water gauge reads 60psi and the gauge measuring the water shooting up into the building reads 80psi. Now both gauges read zero.How can water coming from the city at 60psi travel all the way to the 10th floor without a boost? I do not understand what is happening.

- Naturally okorder /

- Q: I'm only 18 and don't know much about cars, but my car was overheating so me and my boyfriend brought it to a mechanic.They told me it needs a new timing belt and water pump and that alone would be like 1450.. From my research that sounds like bullshit. By the way I drive a 2000 neon, is it THAT hard to work on, or am I being ripped off?

- sounds like a lot of money also i am not sure that's the problem better get a second opinion

- Q: I intend to construct a DIY base camp shower and dish sprayer. I have been searching for an appropriate submersible water pump to plug into a small inverter to a 12-volt cigarette lighter power pack (car jump starter). I need to attach adapters for a hose with a shower head and think that approximately 1+ gallons of draw per minute is practical. I would possibly use a five to six-gallon reservoir, heating water on a car-camping propane stove. My biggest concern is amp draw. Maxi-Jet NJ-400 Submersible Utility Pump, $21, is a powerful aquarium pump with an adjustable flow up to 1.8 gpm.

- Submersible Aquarium Pump

- Q: About 2 months ago I started hearing a noise coming from my bathroom that sounded like loud humming every 3 or 4 seconds after I would turn on the water or flush the toilet. I noticed that when this noise happened the water pressure would increase and then it would go back to normal. Then the noise started to get louder. Last night while my husband was taking a shower the water lost pressure and then completely turned off. Now I have no water at all whatsoever except for maybe a few drops when I turn the faucet on. I have a private well and when I bought the house I was told that the well is underneath one of my bedrooms because the house was built on to and they built over the well. I know I can get to the pump from the crawl space. Has anyone had this problem or does anyone know what it might be or maybe even how much it could cost to fix?

- sounds like a vacum valve problem you need a plumber or a pump person does not sound like a good job for a dyi.

- Q: The garage told me my water pump was pumping quot;weaklyand needs to be replaced.

- Good question (finally). It will pump weakly if it is not turning fast enough or is leaking at a seal. If you have a faulty belt that is slipping it will not turn fast enough. Go to another mechanic.

- Q: It hasnt rain in quite a while, but I havent had any problems with the water or pressure, but it seems like the pump is always quot;onquot;. I purchased this house almost a year ago, never had a well, so I now very little about it. I moved in December, rain season here in NC, and remember the pump going on and off, now its constantly running, Is it normal for the pump to be running that much? any websites to read up on how a water well works?thanks

- In the first place the pump should be able to run constantly without a problem, they're made to do this. In the second place go check your tank, see what the pressure is. You must have a water logged tank First: unplug the electric to the pump and then drain the tank completely. Once this is done make sure the tank is drained, plug it back in, wait and see where it stops at, the pressure. It should be about 55 to 65 pounds. When it stops have someone flush the toilet, it should slowly go down, it may settle without turning on, some do. If so, flush it again. Watch it again. When it starts up, keep your eye on it, it should go back to where it was to start with. If it doesn't then the volume control on the end of the tank, with the small tubing coming from it to the switch is out and should be replaced. You have to turn it all off again, drain the tank and replace the volume control. If the switch doesn't stop but, it comes to the end and doesn't open to stop and keeps running, then your switch control is shot and you'll have to replace that. If you have a bladder tank, it should say on the side, then you should empty the tank, as in the upper questions and then using an air pump put in about 38 pounds or whatever the tank says to put in the bladder, then fill it with water again. See if that's the problem.

- Q: How do you check water pump on 98 deville haveing overhea?

- Not quite sure what you mean, but: Is the water pump malfunctioning? The car is overheating? Well, if it is the water pump, you would need to remove it to check how well it is functioning.

Send your message to us

HN Series Canned Motor Pump with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords