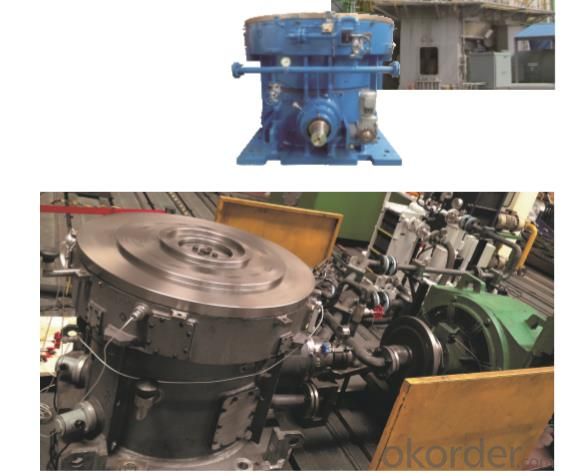

High Quality and widely used Reducer

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The reducer is a kind of independent component which is composed of the gear drive, worm drive and gear - worm drive enclosed in the rigid shell. It is often used as the reducer transmission device between the original moving parts and the working machine.Reducer is a lot of national economy in the field of mechanical transmission device, industry involving product categories include all kinds of gear reducer, planetary gear reducer, worm reducer, also includes a variety of special transmission device, such as growth device, speed regulating device, and including flexible transmission device, all kinds of compound gear, etc.The products and services include metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electric power, construction machinery and petrochemical industries.

China's reducer industry development history has been nearly 40 years, in the national economy and national defense industry in various fields, reducer products have a wide range of applications.Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electrical and electronic equipment, road building machinery, water conservancy machinery, chemical machinery, mining machinery, conveying machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have a strong demand for reducer products.

Huge potential market has given rise to competition in the industry, in the cruel market competition, the reducer industry enterprises must speed up eliminating backward production capacity, to develop the high efficiency and energy saving products, make full use of the national energy-saving products huimin engineering policy opportunities, increase the intensity of product updates, adjust product structure, pay close attention to national industrial policies, to cope with the complex economic environment, maintain a good momentum of development.

- Q:Is the ac servo motor self internal speed control

- For example! The panasonic servo A4 series of electric motors has coders, encoders and motor positions. I didn't open it, I should have been an encoder! The encoder output is connected to the servo drive to control accuracy! When the encoder outputs the pulse signal! The servo actuator can be powered by a single unit and can also be powered by three.

- Q:According to the power of motor, how to select the contactor and switch?

- Must first determine the breaking current, the general low voltage bus bar breaking capacity above 500 kva transformer with 50 kA switches, small transformer low voltage busbar can use 12.5 kA and the breaking capacity of the switch. Secondly according to the current power calculation, and generally current = power/voltage/power factor, if the three-phase motor is divided by 1.732 (because of calculation is single-phase current), choose the rated current higher levels of switch and the contactor. Then select the corresponding tripping characteristics depending on the type of load switch (including tripping accessories), feeder switch will generally choose electromagnetic, should choose the thermomagnetic motor switch type, high perceptual load should choose high grade tripping characteristics of the switch.

- Q:Single phase capacitor ac motor speed regulation why does not have corresponding frequency converter

- It is suitable for low load, such as fan, blower, exhaust fan, etc. The voltage is reduced, the strength of the winding is reduced, the rate of change increases, and the speed decreases. If the load is larger, the voltage is reduced by the lower voltage, and the power of the motor is reduced, and the coil is likely to be overcharged and the coil is hot and burnt. A fan without a speed governor is more than one way of controlling silicon.

- Q:The alternating current is constantly changing, and how is the ac motor going to be controlled?

- There are many methods of rotating magnetic field, such as three-phase winding, single-phase shift phase, short circuit, pulse changing phase, etc.

- Q:What is an ac induction motor

- Because the ac current is entered in the stator coil of the induction motor, such as three-phase alternating current. The stator coil will generate a magnetic field, and the field will rotate as the alternating current changes, which we call a rotating field.

- Q:Three-phase asynchronous ac motor electric speed formula?

- The "extreme number" of a three-phase asynchronous motor is the number of magnetic poles specified in the subfield. The connection mode of stator winding is different, and different poles of stator magnetic field can be formed. The number of poles chosen for the motor is determined by the speed required by the load. The electric current of the motor is only related to the voltage and power of the motor. The three-phase ac motor generates N, S, magnetic poles for each coil, and the number of magnetic poles per machine is the number of poles. Because the poles come in pairs, the motors have two, four, six, eight... Extremely.

- Q:Common problems with ac motor

- ?the high voltage motor shall adopt anti-corona measures in the use of the plateau; (3) the high altitude is unfavorable to the dc motor, and the carbon brush material should be chosen. Why is the motor not suitable for light load? When the motor is light, it will cause: (1) the power factor of the motor is low. (2) the motor is inefficient. It will cause equipment waste and run uneconomic. (1) excessive load; (2) lack of phase; (3) the wind tunnel is blocked; (4) the slow running time is too long; (5) the power supply is too large. 5, why can't you start the machine in a cold environment? The motor is too long in low temperature, it will be: (1) the electrical insulation cracking; (2) the bearing grease freezes; (3) wire joint solder powder. Therefore, the motor should be kept in cold environment, and the winding and bearing should be checked before operation. What are the reasons for the imbalance of the electric current? (1) the three-phase voltage imbalance; (2) bad welding or poor contact of a certain phase of the motor; (3) short circuit in motor winding, or short circuit to ground or phase. (4) connection error.

- Q:Why don't I have a dc 12V without a brush motor and I can connect to a third phase 12V?

- If the voltage is completely same can use frequency converter to drive the brushless dc motor, brushless dc machine is three windings of the synchronous motor, they are ultimately form a rotating magnetic field, is just the difference between the open loop and closed loop.

- Q:There are several methods for alternating current motor

- There are two ways of alternating current motor: 1, power brake, reverse connect braking - will the three-phase power supply cord of the motor exchange of two lines, make access to the motor phase sequence, on the other hand, a rotating magnetic field inversion (in contrast to the rotor turning), the electromagnetic torque is a braking torque, motor soon stopped, must stop the motor when power off, otherwise the motor start to reverse. 2, reverse connect braking pull - motor work normally, the load torque pulling reverse rotation, at this time of the electromagnetic torque is a braking torque, the braking torque motor reverse speed is not fast, but they will not stop the motor

- Q:What is the braking mode of ac motor? What are the characteristics

- The brake method of ac motor has three main kinds: 1, mechanical brake The braking method of turning off the motor rapidly after the electric motor is turned off. Like electromagnetism brake, friction plate brake.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality and widely used Reducer

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches