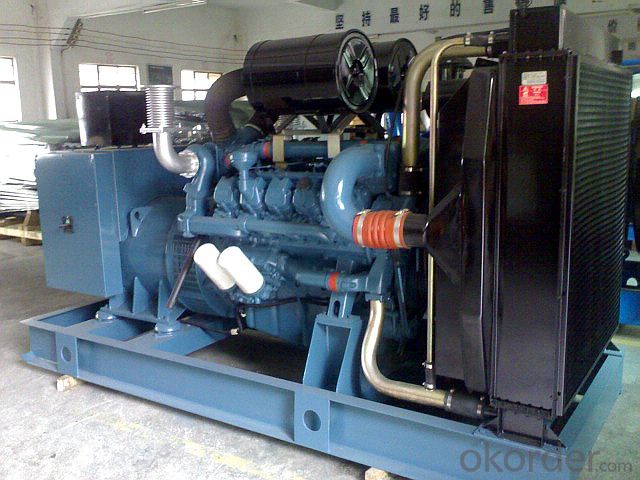

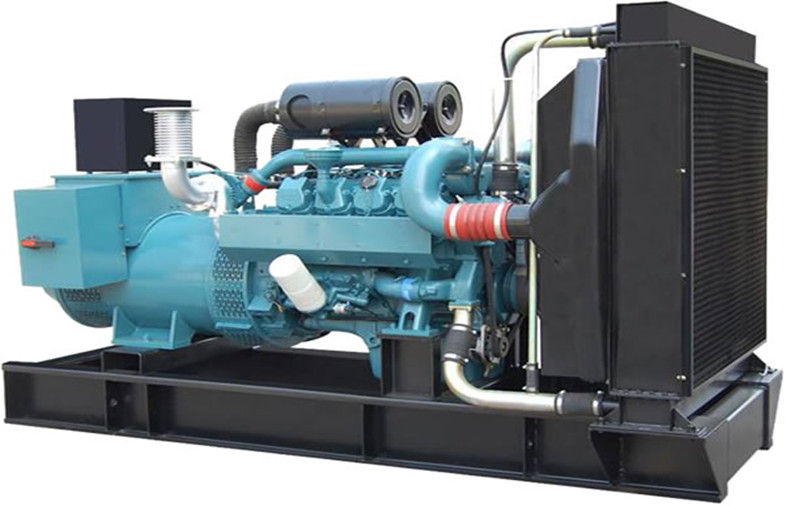

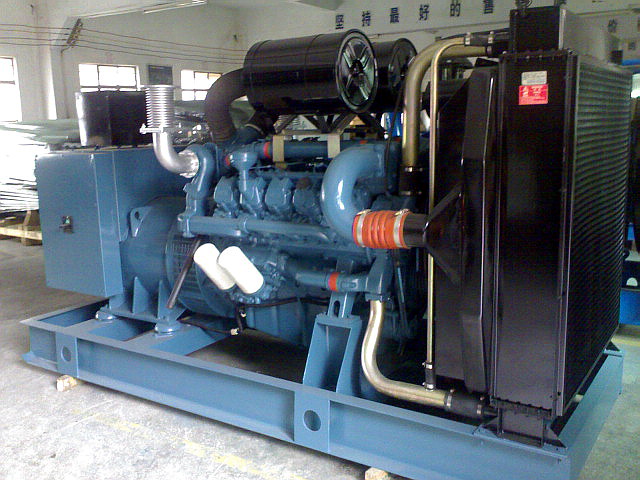

80kva - 600kva Doosan Power Genset Diesel Generator Standby

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

80kva to 625kva Standby Power Generator

1.Doosan Engine With Stamford Alternator

2.High Efficiency , Low Fuel Consumption

3.12 Months Warranty ,CE Approved

80kva - 600kva Doosan Power Genset Diesel Generator Standby

Specifications:

Genset Model | Prime Power | Standby Power | Engine | Fuel Consumption | Cylinder No. | Displacement | Bore X Stroke | ||

KW | KVA | KW | KVA | (g/kwh) | (L ) | (mm) | |||

GNR70DS | 50 | 62.5 | 55 | 70 | DB58 | ≤216 | 6 | 8 | 102*118 |

GNR94DS | 72 | 90 | 80 | 94 | D1146 | ≤216 | 6 | 8 | 111*139 |

GNR138DS | 100 | 125 | 110 | 138 | D1146T | ≤216 | 6 | 8 | 111*139 |

GNR200DS | 140 | 175 | 160 | 200 | D086TI-1 | ≤216 | 6 | 8 | 111*139 |

GNR225DS | 160 | 200 | 180 | 225 | P086TI | ≤216 | 6 | 8 | 111*139 |

GNR275DS | 200 | 250 | 220 | 275 | P126T1 | ≤216 | 8 | 8 | 123*155 |

GNR310DS | 220 | 275 | 250 | 310 | P126TI | ≤216 | 6 | 11 | 123*155 |

GNR350DS | 250 | 310 | 280 | 350 | P126T11 | ≤215 | 6L | 11 | 128*142 |

GNR413DS | 300 | 375 | 330 | 413 | P158LE-1 | ≤213 | V8 | 14.6 | 128*142 |

GNR450DS | 320 | 410 | 360 | 450 | P158LE | ≤212 | V8 | 14.6 | 128*142 |

GNR500DS | 360 | 450 | 400 | 500 | P158LE | ≤212 | V10 | 18.3 | 128*142 |

GNR550DS | 400 | 500 | 440 | 550 | P180LE | ≤212 | V10 | 18.3 | 128*142 |

GNR625DS | 450 | 560 | 500 | 625 | P222LE-I | ≤211 | V12 | 21.9 | 128*142 |

GNR700DS | 500 | 625 | 560 | 700 | P222LE-S | ≤211 | V12 | 21.9 | 128*142 |

Diesel engine:doosan engine

a) Multi-cylinder in-line or veer engine.4-stroke,direct injection

b) Governer Method:electrical or mechanical governor

c) Water cooling

d) Intake method:Natural apirated or turbocharged

e) Electric motor starting system

Alternator: Stamford,LeroySomer, Marathon,Engga

a) Brushless, 4 poles, rotation magnet

b) IP21-23(NEMA1) enclose is standard for all industrial alternators

c) H class insulation system

d) AVR self-regulated, voltage regulation rate: ≤±1%

e) Wide range of flange adaptors and single bearing disc coupling

f) Radio interference restraining accords with the stipulation of VDE0875-N and ISO8528

g) Moisture proof, sand-proof, dustproof, salt-proof and vibration-proof

Control plane :

a)Automatic alarm system: the unit has the acoustic-optics alarm system and arrestor for any situation as the start defeat, the water is over temperature the oil pulls down, over speed, over load and over current

b) Operation display:

i)Unit voltage, tri-phase load current and frequency display

ii)Water temperature, oil pressure display

iii)Fuel level, fuel temperature dieplay

iv)Audible and visual alarm lamps and buzzers

c)Emergency stop button

d)Three protection

Accessories

a) Standard accessories: Standard 40 radiator mounted on skid, Common steel frame, circuit breaker, damper, exhaust silencer, flexible pipe, battery and connecting wires, Standard tools kit, operation manual and document.

b) Optional accessories: Engine coolant and oil heater, alternator space heater, cooling for heat exchanger, communication interface, battery charger by main supply, daily fuel tank, ATS and paralleling system, soundproof canopy and moving trailer.

Warranty policy

Guarantee for one year or 1000 hours whichever reach first from ex-factory date. During the guarantee period, Genor will provide the free easy-damageable spare parts of diesel engine caused by our quality of production or raw material. After expiration, Genor provides cost spare parts maintenance of gensets.

- Q: If the value of the capacitor on a motor is smaller, it can also be installed in other motors

- The capacitance is ageing and the work is unstable and soon expires.I hope my answer will help you.

- Q: What is the difference between explosion-proof motor and ordinary motor

- Compared with the general motors explosion-proof electric motor is characterized by: (1) meet the requirements of type increased safety explosion-proof motor, a series of reliable measures to prevent spark, arc and danger of high temperature, can be safe operation in explosive dangerous location 2 zone. (2) the excitation control system is reliable by using the brushless excitation, setting the rotary rectifier disc and the static excitation cabinet. It is accurate to be accurate, without impact. The excitation system loses step protection and is reliable, and the whole step is strong. The circuit design is reasonable, the discharge resistance is not hot in the work. Excitation current adjusts the scope width. (3) synchronous machine, ac exciter and rotating rectifier disk coaxial. The rectifying disk is located between the main motor and the exciter, or outside the bearing seat.

- Q: How does servo motor understand? What is a servo motor? What about motors? What's different about servo motors and other motors?

- Servo is to make the object's position, orientation, and state is accused of output can follow the input target given value (or) any change of the automatic control system, to put it bluntly, is a precision closed-loop control system. Dc motor and ac motor. For the daily application, it is mainly the ordinary motor, the frequency conversion motor, the servo motor. The servo motor is characterized by the power line and the signal line. It has its own encoder and so on, and given a speed, it will be running at that speed. And because there is an encoder inside, it knows how many circles it has turned, and it can precisely stop the motor from being in a certain position. So in accurate control, the servo motor is chosen. It can be used for constant speed control, constant torque control, positioning control and so on.

- Q: What is the difference between a general motor and a high-speed motor?

- Ordinary ac motor is restricted by the maximum synchronous speed, which can not reach high speed, dc motor (especially brushless motor) can achieve higher speed. The static balance and dynamic balance of high speed motor are high.

- Q: Is permanent magnet power saving?

- In theory, it saves electricity. The permanent magnet motor is compared to the ordinary motor with "three high", high efficiency, high power factor and high power torque. The first two "high" has shown its more energy-saving than general motors. In addition, the permanent magnet (synchronous) motor which has reached the other synchronous motor current regulated torque, the purpose of without rotor winding, don't need to give the rotor excitation, it reduces the energy consumption.

- Q: What is an electric motor

- Motor is a device that converts electricity into mechanical energy. It USES the electric coil (which is the stator winding) to generate a rotating magnetic field and is applied to the rotor (such as the cage of a cage) to create the magnetoelectric rotation torque. Motor by using the power divided into dc motor and ac motor, electric power system in most of the motor is ac motor, can be synchronous motor or induction motor (motor stator magnetic speed and rotor rotating speed is not synchronized rate). Motor is mainly composed of stator and rotor, the direction of motion of the wire in the magnetic field force with the direction of current and magnetic induction line () in the direction of magnetic field direction. The operating principle of an electric motor is the effect of the magnetic field on the current, making the motor spin.

- Q: What is the main difference between the step motor and the ordinary motor?

- Step motor is pulse control, one pulse is a step; General electric motor is called induction motor, which is controlled by analog quantity, and the electricity is transferred.

- Q: Can you use a transducer to control the general motors? Recently, the factory has to renovate two 150 kw electric motors, which were previously controlled by the star delta, and now change the frequency converter, the electric motor is near the stove, the ambient temperature is higher. Please give me your opinion, thank you

- If you don't reload frequently, not reload, you don't have to work long hours at low frequencies, and you have a fan that's basically ok.

- Q: What is the difference between the brake step motor and the step motor?

- Difference is the brake stepper motor is a kind of applied in special working environment of the motor For example, up and down movement of the table When braking power stepping motor will not move, while ordinary will continue to exercise, it is likely to hurt people or equipment

- Q: Is the servo motor more than the general motors? Why is that?

- The average injection machine can also save energy, whether it's a servo or a frequency converter, which can be used to save energy, but the difference is as follows: If you use a converter, the cost is low, (the converter cost is about 500 to 600 yuan per KW, and the servo is about 1,200 ~ 1500 yuan per KW). The frequency conversion of the frequency converter is lower than the servo, (the frequency of the frequency converter is 20% ~ 50%, and the servo is usually 30% ~ 70%). 3. The frequency converter with low maintenance cost, frequency converter by the localization of more than 10 years of history, has become increasingly stable, many occasions can be comparable with imported, while the servo is not very mature, average life is not too long, once out of the problem, the cost is very high. It depends on your financial situation and going to the statement, the company also produces servo, not in the fight against others, but after so many years of experience, the company's injection molding machine frequency conversion electric saving is very stable, like some big enterprises such as byd, unified group and other large enterprises are successfully used for years

Send your message to us

80kva - 600kva Doosan Power Genset Diesel Generator Standby

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords