High Pressure Multistage Boiler Feed Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

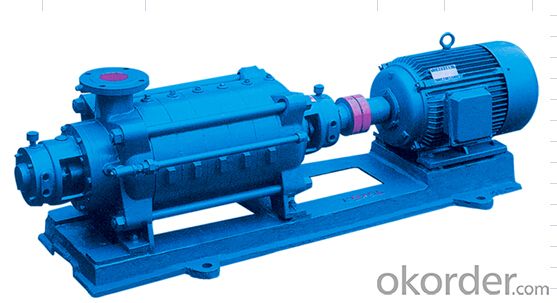

High Pressure Multistage Boiler Feed Water Pump

1.Structure of High Pressure Multistage Boiler Feed Water Pump Description

Boiler Feed Centrifugal Multistage Water Pumpis used for transporting pure water (particles density shall be max.1%by volumeand granular size shall be max 0.1mm in dimeter) of the liquids with physical and chemical properties similar to pure water. Type MD pump is applied with wear resist material, especially suitable for mineral drainage. The particles density shall be max. 1.5% (Max. of the granular diameter is 0.5 mm).The liquid temperature ofD, MD pumps shall be lower than 80°C.

2.Main Features of the High Pressure Multistage Boiler Feed Water Pump

• Compact structure, good appearance, low construction

•Operation stably, same inlet and outlet

•Convenient installation and maintenance

•Customized design is available, OEM and ODM are welcomed.

•Horizontally and vertically installation as different pipeline system

3. High Pressure Multistage Boiler Feed Water Pump images

4.High Pressure Multistage Boiler Feed Water Pump Specification

Item | Multistage Pump |

Multistage Pump | Horizontal Multistage Pump For Pure Water |

Model | CMD |

Material | Cast iron,Stainless steel |

Mode | Horizontal |

Color | Blue |

Temperature | <=80°c< span=""> |

Seal | packing seal |

Theory | Centrifugal Pump |

Structure | Multistage Pump |

Usage | Water |

Power | Electric |

Standard or Nonstandard | Standard |

Fuel | Diesel |

Pressure | High Pressure |

Application | Hot and cold pure water |

Outlet Diameter | 40-500mm |

Capacity | 6-1250 m3/h |

Head | 75-1800m |

Rotation Speed | 1450-2950r/min |

Power | 5.5-2400kW |

Certificate | ISO9001 |

Feature | High efficiency,Easy maintenance |

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also

provide the pump model you are using now, price will be calculated as per the pump model, if not, we willrecommend relevant product for reference.

- Q: Working principle and diagram of axial piston pump with pressure compensation variable

- The size of the outlet flow pressure compensated variable displacement pump with outlet pressure of approximately in a certain range according to the constant power curve. When the pressure oil from the main part of the channel (a), (b), (c) into the inferior vena cava (d) variable shell, oil by the channel (E) respectively into the channel (f) and (H), when the spring force is greater than the oil (f) into the lower end of the piston ring servo hydraulic thrust area when the oil liquid (H) to the chamber (g), push the variable downward movement of the piston, the pump flow increases. As for the hydraulic servo piston end thrust force ring shaped area is greater than the spring when the servo piston moves upward, blocking channels (H), the (g) (I) through the cavity of the oil cavity pressure relief, at this time, the piston moves up, the variable head angle decreases, the pump flow rate decreases.

- Q: How about the depreciation of vacuum pumps?

- (three) appliances, tools, furniture and so on related to the production and operation activities, for 5 years;(four) aircraft, trains, ships and other means of transport for 4 years;

- Q: How much water does the water ring vacuum pump run for an hour? If there is no steam separator, does the water vaporize?

- For example: water storage is relatively small, it needs to reduce the temperature of the heat exchanger. If the tank is relatively large, it does not need cooling water circulation pump again when the temperature is very low, there is no need to heat exchanger. So you need to ask how much water this is not OK.In a soda separator problem:

- Q: What are the functions of a disposable infusion pump?

- This is a very professional question, ha!I only know disposable infusion pumpsAttached: intelligent medical infusion pump and its application

- Q: What should I pay attention to when buying a pump?

- There are hundreds of water pump manufacturers in China, some of the family owned private enterprises are assembled in some areas, and the quality of the products is very good and bad, which makes it difficult to choose and buy. The main points are as follows:First, according to the required flow, lift, shaft power, efficiency, the necessary cavitation margin (or suction) and the use of conditions, the initial determination of the pump type, name, select the rated value and the required parameters of the same pump.

- Q: What is the relationship between the minimum suction vacuum of a pump and the required cavitation?

- Suction is allowed to pump the vacuum from the distance from the inlet, which is part of the field installation.The manufacturer of cavitation allowance is closely related to the design and process of pump. Estimation formula: cavitation allowance =10.33 meters - allow suction of -0.5 meters (safety).

- Q: I live on the 8 floor. Often there is no water. Life is very inconvenient. What kind of pump do I have to install? What should I pay attention to when I buy it? What's the pump for that brand? Should it be installed in that position?

- Installation method of hydraulic pump(1) according to the technological requirements and the cavitation conditions of the pump, the installation height check and the civil engineering of the foundation are carried out.(2) prepare a series of flat washers and wedge gaskets of different thickness before installation.(3) according to the characteristics of the pump conveying medium, determine the material of the gasket at the connection and process the gasket.

- Q: Operating procedures for measuring pumps

- First, preparation and inspection before starting1. Check to make sure that the drain line is equipped with a safety valve with the correct set pressure.2. Check the screws for the liquid end parts.

- Q: Suction stroke and lift of water pump

- Lift pump lift pump can lift refers to the height, usually expressed in H, the unit is m. centrifugal pump lift to the impeller center line, divided by two parts. The vertical height from the pump impeller centerline to the water surface, the water pump to suck water up to the height, called water head, referred to as suction pump impeller; from the center line to the vertical height of the water tank, the water pump can put pressure on the height, called water pressure head, referred to as the pressure. The pump head = + suction head pressure water head should be pointed out that the nameplate marked head refers to the pump itself can produce lift, it is not with the pipe flow friction resistance caused by the loss of lift. In the selection of water pump, attention can not be ignored. Otherwise, will be pumping Sheung Shui.

- Q: No negative pressure water supply equipment, both the main pump and auxiliary pump, power is not the same, how to choose the control cabinet?

- Non negative pressure variable frequency water supply means no negative pressure superposed water supply equipment. When running, it is connected directly to the water supply pipe. Always test the pressure of tap water pipe network and water supply pipe network pressure control system, when the water pressure is lower than the pressure required by the user, the frequency conversion device based on water automatically control the pump speed through the steady flow compensator of water balance, maintain a constant pressure water supply. In the multi pump system, the control system can automatically dispatch the water pump according to the water consumption. It can balance the working time of the pump and ensure the pressure of the water supply. When the water supply pressure satisfy the required pressure, the system automatically stops the pump by the external water supply pipe network directly. CJWFG-DYG non negative pressure superposed water supply system:

Send your message to us

High Pressure Multistage Boiler Feed Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords