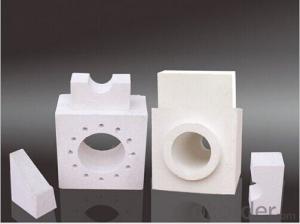

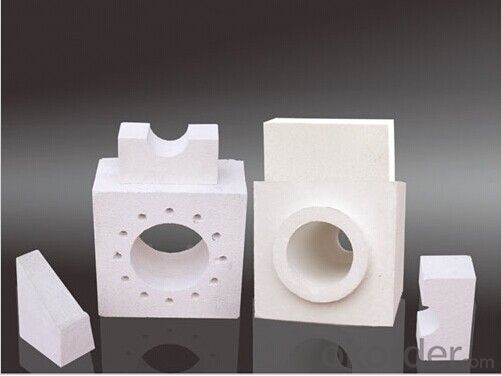

High-Aluminum Low-Iron Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

High aluminum refractory brick belongs to gender refractory materials with its thermal stability.

Feature:

1.bricks are made from high quality bauxite

2.dry pressed

3.burned under tunnel kiln

4.accurate dimension

5.high strength

Product specification: Can be used in various kilns because of its cheapness and general tray package. Among all of the refractory materials, it is the mostly used in the key positions.Molding method: it has down draft kiln and tunnel kiln and the general sintering temperature is 1360-1480 degrees. It is a kind of aluminosilicate refractory product which aluminum oxide (Al2O3) content is higher than 48%.

Item | Properties | |||||

LZ-80 | LZ-75 | LZ-65 | LZ-55 | LZ-48 | ||

Al2O3 ,% | 80 | ≥75 | ≥65 | ≥55 | ≥48 | |

Refractoriness °C | ≥1790 | ≥1790 | ≥1790 | ≥1770 | ≥1750 | |

Bulk density,g/cm3 | 2.65 | 2.5 | 2.45 | 2.4 | 2.3 | |

Softening temperature under load | 1530 | ≥1520 | ≥1500 | ≥1470 | ≥1420 | |

Permanent linear change,% | 1500°CX2H | +0.1 -0.4 | +0.1 -0.4 | +0.1 -0.4 | +0.1 -0.4 |

|

1450°CX2H |

|

|

|

| +0.1 -0.4 | |

Apparent porosity,% | 22 | ≤23 | ≤23 | ≤22 | ≤22 | |

Cold Crushing strength Mpa | 55 | ≥50 | ≥45 | ≥40 | ≥35 | |

Application | All industrial furnace | |||||

- Q: What are the safety precautions when working with insulating fire bricks?

- When working with insulating fire bricks, it is important to follow certain safety precautions to minimize potential hazards. These precautions include wearing appropriate personal protective equipment such as gloves, safety glasses, and a dust mask to protect against irritation and inhalation of dust particles. It is also essential to work in a well-ventilated area to avoid the accumulation of harmful gases. Additionally, workers should be cautious of sharp edges and corners when handling the bricks, as well as avoid excessive lifting to prevent strain or injury. Lastly, it is crucial to store and handle the bricks properly to prevent any damage or breakage that could lead to accidents.

- Q: Can insulating fire bricks be used as a lining material for boilers?

- Yes, insulating fire bricks can be used as a lining material for boilers. Insulating fire bricks are made from lightweight refractory materials that have high insulating properties. These bricks are designed to withstand high temperatures, making them suitable for use in boilers where temperatures can reach up to several hundred degrees Celsius. The insulating properties of these bricks help to reduce heat loss, improving the energy efficiency of the boiler. Additionally, insulating fire bricks are resistant to thermal shock, which is crucial for withstanding the rapid temperature changes that occur in boilers. Overall, insulating fire bricks are a suitable choice for lining boilers due to their excellent insulating properties and ability to withstand high temperatures.

- Q: Can insulating fire bricks be used in the construction of refractory-lined vessels?

- Yes, insulating fire bricks can be used in the construction of refractory-lined vessels. Insulating fire bricks are specifically designed with low thermal conductivity, which makes them ideal for applications where insulation is required. In the construction of refractory-lined vessels, insulating fire bricks are often used in the outer layers of the lining to provide insulation and reduce heat loss. This helps to improve energy efficiency and maintain high temperatures inside the vessel. However, it is important to note that insulating fire bricks may not be suitable for all parts of the refractory lining, especially in areas where high mechanical strength or resistance to chemical attack is required. In such cases, other types of refractory bricks may need to be used.

- Q: Do insulating fire bricks require maintenance?

- Maintenance is required for insulating fire bricks. Despite their reputation for durability and ability to withstand high temperatures, it is important to regularly maintain them to ensure they perform at their best and last a long time. One crucial aspect of maintenance is periodic cleaning. Over time, insulating fire bricks can collect dust, soot, and other debris, which can impact their insulation properties. It is therefore advisable to clean the bricks regularly to eliminate any build-up. This can be achieved by using a soft brush or a mild cleaning solution. Another vital aspect of maintenance involves checking for any cracks or damages. It is essential to inspect the bricks for signs of wear and tear to identify and address any issues before they worsen. Cracks or damages can compromise the insulation and stability of the bricks, so they should be repaired or replaced as necessary. Additionally, it is important to monitor the condition of the mortar or refractory cement used to hold the insulating fire bricks together. Over time, the mortar can deteriorate due to exposure to heat and other elements. Regularly inspecting and repairing any damaged mortar helps to maintain the structural integrity of the fire bricks. Furthermore, it is crucial to adhere to the manufacturer's instructions and recommendations for the specific type of insulating fire bricks being used. This may involve following guidelines for installation, temperature limits, and any other specific care instructions. In conclusion, while insulating fire bricks are sturdy, regular maintenance is required to ensure they perform optimally and have a long lifespan. Proper cleaning, inspecting for damage, and following the manufacturer's guidelines are essential components of maintaining insulating fire bricks.

- Q: Are insulating fire bricks suitable for insulation in boilers?

- Yes, insulating fire bricks are suitable for insulation in boilers. Insulating fire bricks are made from lightweight materials such as clay and alumina, which have excellent insulating properties. They have a low thermal conductivity, meaning they are effective at preventing heat transfer and can help to significantly reduce heat loss in boilers. Additionally, insulating fire bricks are resistant to high temperatures, making them suitable for use in boilers where high heat is generated. They are also durable and can withstand the harsh conditions inside a boiler, including exposure to intense heat and corrosive gases. Overall, insulating fire bricks are a popular choice for boiler insulation due to their thermal efficiency and ability to withstand high temperatures.

- Q: Can insulating fire bricks be used in rotary kilns?

- Yes, insulating fire bricks can be used in rotary kilns. Insulating fire bricks are designed to have low thermal conductivity, which helps to reduce heat loss and improve energy efficiency in high-temperature applications like rotary kilns. Additionally, these bricks are lightweight and have good thermal shock resistance, making them suitable for the harsh and dynamic conditions within a rotary kiln.

- Q: Can insulating fire bricks be used for insulation in aluminum smelters?

- Yes, insulating fire bricks can be used for insulation in aluminum smelters. Insulating fire bricks are made from special lightweight materials that have high insulating properties, making them ideal for applications that require high-temperature insulation. Aluminum smelters operate at extremely high temperatures, and insulating fire bricks can effectively withstand and retain the heat, preventing heat loss and improving energy efficiency. Additionally, these bricks are resistant to thermal shock, a common occurrence in smelting processes, which makes them highly suitable for use in aluminum smelters. Insulating fire bricks can also provide a protective barrier, reducing the risk of heat damage to the surrounding structures and equipment. Therefore, using insulating fire bricks for insulation in aluminum smelters can enhance thermal efficiency, reduce energy consumption, and ensure a safe and efficient smelting process.

- Q: How thick are insulating fire bricks?

- The thickness of insulating fire bricks usually falls between 2.5 and 4 inches (6.35 to 10.16 cm), varying based on the manufacturer and the intended purpose of the bricks. With the ability to endure extreme temperatures and offer exceptional insulation, these bricks are well-suited for application in kilns, furnaces, and other environments with high temperatures.

- Q: Can insulating fire bricks be used for insulation in steel mills?

- Yes, insulating fire bricks can be used for insulation in steel mills. Insulating fire bricks are made from lightweight refractory materials that have excellent insulating properties and can withstand high temperatures. They are designed to minimize heat transfer and maintain the desired temperature inside the furnace or kiln. In steel mills, these bricks can be used to insulate the walls, floors, and roofs of the furnaces, ladles, and other equipment. This insulation helps to reduce heat losses, improve energy efficiency, and ensure consistent and controlled heating processes. Additionally, insulating fire bricks can provide thermal stability and protect the steel mill equipment from excessive heat, contributing to longer equipment lifespan and reduced maintenance costs.

- Q: Are insulating fire bricks chemically resistant?

- Insulating fire bricks are generally chemically resistant to a wide range of substances. These bricks are typically made from high-quality refractory materials such as alumina, silica, or a combination of both. These materials have excellent resistance to chemical attack, making insulating fire bricks highly resistant to the corrosive effects of various chemicals. However, it is important to note that the chemical resistance of insulating fire bricks can vary depending on the specific composition and manufacturing process. While they are generally resistant to most chemicals, there may be certain aggressive chemicals or extreme conditions that could potentially degrade or erode the bricks over time. To ensure the optimal chemical resistance of insulating fire bricks, it is recommended to consult the manufacturer's specifications or seek expert advice for specific applications. This will help ensure that the bricks are suitable for the intended chemical environment and will perform reliably over the desired lifespan.

Send your message to us

High-Aluminum Low-Iron Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords