High Alumina Brick for Hot-Blast Stove

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for High Alumina Brick for Hot-Blast Stove

| Place of Origin: | China (Mainland) | Shape: | Brick | Material: | Alumina Block |

| SiO2 Content (%): | 22 | Al2O3 Content (%): | 65-75 | Model Number: | JDL-65/JDL-75 |

| Brand Name: | Refractoriness: | 1790 °C | Cetification: | ISO9001 |

Packaging & Delivery

| Packaging Details: | Fumigation wooden pallets+paper angle bead+PET strap+stretch film. |

| Delivery Detail: | More than 30 days after signing the contract |

Specifications for High Alumina Brick for Hot-Blast Stove

Characteristic:

1.High-temperature resistance

2.Lower creep rate

3.High strength

4.Good thermal shock resistance

![]()

This product is made by superfine calcined bauxite, additive and high-quality combined clay. This product has good performances of hot flue scouring resistance and corrosion resistance. Its apparent porosity is lower,strength is high and its creep rate is lower, so it means that this product can well keep stability under the load and high temperature.

![]()

| Item | JDL-65 | JDL-75 |

| Al2O3 % | 65 | 75 |

| Apparent porosity % | 22 | 20 |

| Bulk density g/cm3 | 2.4 | 2.6 |

| Cold crushing strength Mpa | 55 | 60 |

| Reheating linear change % | 1450°C×2h +0.1~-0.2 | 1550°C×2h +0.1~-0.2 |

| Creep rate 0.2MPa×50h % | 1400°C ≤0.8 | 1550°C ≤0.8 |

| Application | combustor, grid room, wind mix chamber | combustor, grid room, wind mix chamber |

![]()

It is widely used in regenerative chamber, combustion chamber,communication pipe and other parts of hot blast stove.

![]()

1.Strong professional:

A:The manager of our company has twenty years working experience in refractory product, technology and trading. He has professional function on a various refractory’ s production materials, process control, quality supervision and package delivery.

B: .Company staff are very familiar with refractory and professional knowledge is very good .

C:Company staff are all college culture level.

2. .Annual supply:

Our company has a dozen cooperative production factories which are better in productive technology and quality management. All the factories has passed ISO9001 quality management system certification. And the annual supply of dense shaped and unshaped refractory product is 100,000-200,000 tons.

3. Annual exports:

Now we have exported more than ten countries , such as Asia ,Europe and South America.The average annual export amount is 10 million Yuan , about $1.6 million.

4. Production equipment:

Production and testing equipments are new, complete and automated or semi- automated. Such modern facilities and equipments have provided the fine technical guarantee for the production and testing.

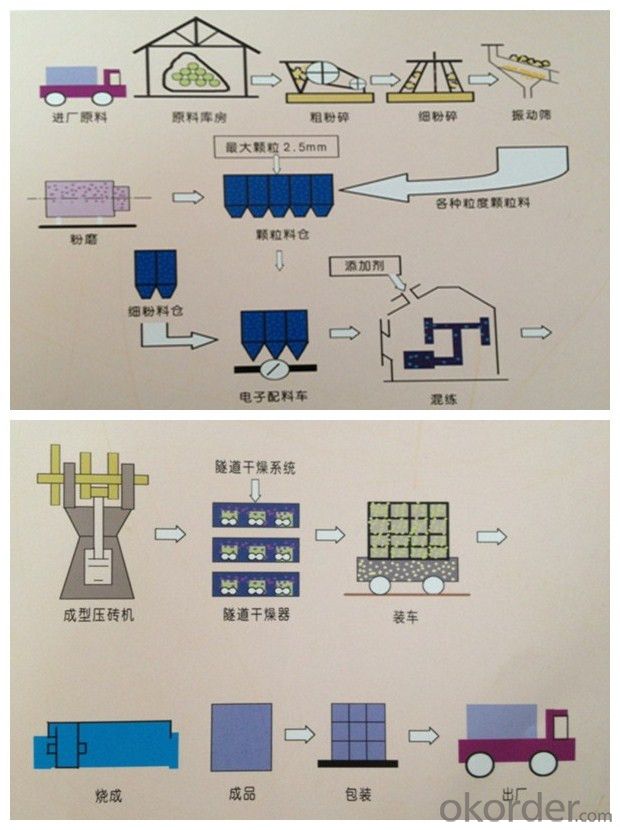

5. Process flowdiagram:

6. Order processing:

After the contract is signed, the relevant responsible person tracked production progress, product quality and product packing aperiodically. During the term of contract sent on time with quantity and quality guaranteed.

- Q:How much is the bending temperature aluminum silicon carbide brick for torpedo car

- The product has the advantages of high temperature, little creep, strong corrosion resistance and good thermal shock resistance, and is suitable for large and medium-sized hot blast stoves.

- Q:What is the standard classification of high alumina bricks and high alumina bricks?

- Refractory brick is non-metallic materials can be classified according to a kind of inorganic material, high aluminum brick, clay brick, magnesia brick, corundum brick, mullite bricks, silicon carbide materials such as brick, high alumina brick is used as a relatively wide range of products in accordance with the refractory brick high alumina refractory materials by high aluminum brick is generally divided into Al2O3 content three: I - II - >75% Al2O3 content; the content of Al2O3 is 60 ~ 75%; III - Al2O3 content from 48 to 60%.

- Q:What is the difference between metal compounds and metal solid solutions?

- A series of intermetallic compounds occurring between transition metals in intermetallic compounds. The most important are L sigma sigma phase and ves phase, they are topologically close packed (TcP) phase, they consist of a small atomic radius of a dense layer, which is inlaid with a large atomic radius of atomic structure, this is a highly dense pile. In addition to atomic size factors, their formation is also influenced by the concentration of electrons.

- Q:What kind of material is the general metal case?

- Ordinary computer chassis and the material itself does not produce high-energy radiation, only in the space environment of the computer is the external defense requirements, and in the space structure, the use of lead as protective materials, unbearable weight.

- Q:How much is one ton of high alumina refractory brick?

- Three high aluminum refractory brick Zhengzhou Kuwait is generally around 800. 32 years of experience, good.

- Q:Which is better, the soft core or the hard core?

- The use of each of the single core copper wire with low line, 1.5 square with cap line home, socket 2.5 square, air conditioning to walk alone line 4 square can, when the terminal box into a socket with leakage protection switch, prevent overload and short circuit.

- Q:What is the price of the latest thermal insulation material?

- There are many kinds of insulation materials, and the price will fluctuate with the market. Small quantities of inquiry or procurement, then go directly to the local thermal insulation market, a wide variety of prices are basically the market price.

- Q:What causes breakage of refractory bricks?

- Refractory brick is a non metal mineral products can be used in the high temperature of 1550 DEG C under belongs to a class of inorganic, used in high-temperature furnace lining materials as protection kiln, which causes damage, usually have these points.Furnace temperature is not clear, there is no corresponding choice of refractory bricks.Physical impact, abrasion and erosion cause damageChemical factors, especially chemical industry, should be made of refractory bricks, which should be resistant to penetration and erosionIV: products from the factory when the factory did not pass the quality inspection standards

- Q:What are the specific raw materials for plastic pallets?

- With excellent mechanical properties, its strength and elasticity are higher than HDPE, and it has good flexural fatigue resistance. It has good heat resistance and good chemical stability. Besides being concentrated by concentrated sulfuric acid and concentrated nitric acid, it is relatively stable to other chemical reagents. The high frequency insulation performance of polypropylene is excellent because of its almost no water absorption, so the insulation performance is not affected by temperature.

- Q:What are the high temperature refractory mortars made of?

- Products used in metallurgy, building materials, machinery, chemical, power industry, industrial thermal furnace, for masonryBuilding clay brick, high alumina brick and corundum brick have the characteristics of full grey seam, good airtightness, high bonding strength, high temperature performance and suitable construction time

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Alumina Brick for Hot-Blast Stove

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords