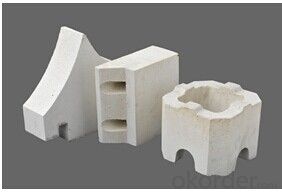

High Alumina Sillimanite Fire Brick for Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Resistance to corrosion and erosion;

2.Least contamination for molten glass;

3.Improve the productivityaa

4.Long life

Features:

The sillimanite brick is made of sillimanite minerals.After high temperature calcination,it become mullite and

dissociate silicon dioxide.Generally use high-temperature firing method and slurry casting method to produce.

1.Good thermal stability.

2.Strong resistance to chemical attack.

3.It is the first choice of stable material for glass forming.

Applications:

1.Widely used in glass furnace,such as regenerator arch.

2.Mainly used in the blast furnace.

3.

Sillimanite brick physiochemical index:

Item | Properties | ||||||

Sillimanite | Andalusite | Cordierite and mullite | Pouring sillimanite | ||||

LS-65 | L-60 | H-60 | HS-55 | SPCD-50 | SPCD-60 | CS-58 | |

AL2O3(%) | 65 | 60 | 60 | 55 | 50 | 60 | 58 |

Fe2O3(%) |

|

|

|

|

|

| 0.8 |

Refractoriness,°C | 1790 | 1790 | 1790 | 1770 | 1770 | 1790 | 1790 |

Apparent porosity % | 22 | 22 | 22 | 22 | 24 | 24 | 26 |

Cold Crushing strength MPa | 50 | 50 | 40 | 40 | 40 | 50 | 50 |

Bulk density,g/cm3 | 2.2 | 2.2 | 2.5-2.7 | 2.5-2.7 | 2.4 | 2.4 | 2.2 |

Softening temperature under load,KD°C≥ | 1550 | 1500 | 1500 | 1450 | 1450 | 1500 | 1450 |

Permanent linear change,%(°C×h) | ±0.2 | ±0.2 | ±0.2 | ±0.2 | (1000°C)≤±0.5% | (1000°C)≤±0.5% | 1400°C×2h +0.1 -0.3 |

Application | Used for temperature change severe industrial furnace and thermal lining equipment | All sorts of kiln burner brick and ceramic kiln brick | All industrial furnace | ||||

- Q: In 2016, a few of the traditional refractory materials will be able to survive

- The other is in large enterprises and individual has the unique advantage of the small enterprises, with independent technology system, production equipment advanced, there are certain funds set up to deal with risk, timely reform, such enterprises compared to a few years ago the productivity and sales or have declined, but overall is still in the stage of production increased steadily.

- Q: What is the heat preservation material used in a laboratory furnace?

- Silicon carbide (SiC) is made from quartz sand, petroleum coke (or coal tar), sawdust (green salt produced when adding green silicon carbide) and other raw materials by smelting with resistance furnace at high temperature. Silicon carbide also rare minerals in nature, Mo sangshi. Silicon carbide, also known as carbon silica. Silicon carbide is the most widely used and the most economical kind of refractory materials in C, N, B and other non oxide refractory materials. It can be called "carborundum sand" or "refractory sand".

- Q: Which is better, the soft core or the hard core?

- When the current through the wire, it will produce a magnetic field in the vertical plane space of the wire, if there is a current two wire close by in the same direction, because they produce a magnetic field in the direction is opposite, it will produce a repulsive force is due to the magnetic field force. They will mutually inhibit current intensity of the other party, caused by the reduction of current in the wire, this inhibition of each current intensity, we called wire inductance. When the AC current line frequency is high, the inductance is stronger.

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- The super high alumina brick in high alumina refractory brick has the highest refractoriness, and the corresponding production cost is higher.

- Q: What is the difference between high alumina brick and clay brick?

- Lightweight high alumina bricks are usually made of high alumina bauxite clinker with a small amount of clay. After grinding, the bricks are poured and shaped in the form of slurry by gas or foam method. They are fired at 1300~1500 DEG C. Sometimes industrial alumina can be used instead of some bauxite clinker. Used for lining and insulation of masonry kilns, as well as for areas where there is no strong, high temperature molten material erosion and erosion. When contacting the flame directly, the surface contact temperature shall not be higher than 1350 degrees centigrade.

- Q: How are the grades of high alumina bricks differentiated?

- In China, the content of Al2O3 in high alumina brick is usually divided into three categories: I, etc. - Al2O3 content > 75%; II, etc. - Al2O3 content is 60 to 75%; III and so on - Al2O3 content is 48 ~ 60%.

- Q: Is glass wool inorganic thermal insulation material?

- The use of glass wool, glass wool is usually used as raw materials of various types of insulation materials, such as glass wool board, glass wool, glass wool, glass wool pipe, can be used in the following areas:1) roof insulation, cold protection, sound-absorbing materials; 2) building exterior wall insulation and cold protection; 3) entertainment places, theaters, television stations, radio stations, laboratories, sound absorption treatment.

- Q: What causes breakage of refractory bricks?

- There are many factors that lead to the damage of refractory brick, can be divided into: the chemical loss (e.g. salt penetration, redox phenomenon), heat loss (burning, thermal shock), mechanical loss (kiln deformation, thrust, brick masonry quality etc.).

- Q: Use of high alumina refractory bricks?

- High alumina brick refractory than clay refractory bricks and brick refractory degree are higher, up to 1750~1790 DEG C, which belongs to high-grade refractory materials.

- Q: What are the lining structures of lime rotary kilns and what are the requirements for refractories?

- The rotary kiln lining structure of rotary kiln and requirements on refractories calcining active lime according to the general output is divided into Nissan 300t, 400 t, 600 t, 800 t, 1000 t, 12000 t of kiln type, calcining zone temperature at 1350 degrees celsius. The kiln is divided into a discharge end, a cooling zone, a burning zone, a preheating zone and a feeding end, and the temperature of each section of the kiln ranges from 1000 DEG C to 1350 DEG C, and the requirements for refractory materials are different. The kiln refractory materials not only to withstand the high temperature impact, but also need to bear the material erosion, kiln rotation stress produced, so not only on the physico-chemical properties of refractory materials have strict requirements, but also for the construction of brick should be strictly.

Send your message to us

High Alumina Sillimanite Fire Brick for Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords