Gold Aluminum Foil Sheets for Decorative Aluminum Roof Panels Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Roof Panels for Decoration Supply

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Aluminum Roof Panels for Decoration Supply

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

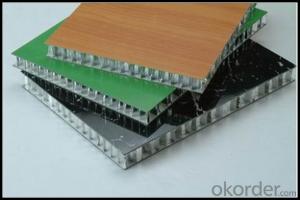

3. Aluminum Roof Panels for Decoration Supply Images

4.Specification of Aluminum Roof Panels for Decoration Supply

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: How do aluminum sheets perform in terms of thermal expansion?

- Aluminum sheets have a relatively high coefficient of thermal expansion, meaning they expand significantly when exposed to heat and contract when cooled. This property can be both advantageous and challenging depending on the application, as it allows for easy shaping and forming but may also cause dimensional changes and potential structural issues under extreme temperature fluctuations.

- Q: Consider an aluminum wire of diameter 0.580 mm and length 28.0 m. The resistivity of aluminum at 20.0°C is 2.82 10-8 Ω · m.(a) Find the resistance of this wire at 20.0°C. ___________Ω(b) If a 9.00-V battery is connected across the ends of the wire, find the current in the wire. __________A

- Resistivity Of Aluminum Wire

- Q: How do you prevent galvanic corrosion when using aluminum sheets with concrete?

- To prevent galvanic corrosion when using aluminum sheets with concrete, several preventive measures can be taken: 1. Barrier Coating: Apply a barrier coating or paint on the aluminum sheets to separate them from the concrete. This coating acts as a protective layer, preventing direct contact between the aluminum and the concrete, thereby reducing the chances of galvanic corrosion. 2. Insulation: Introduce an insulating material between the aluminum sheets and the concrete. This material can be a non-conductive plastic or rubber sheet that effectively isolates the aluminum from the concrete, minimizing the risk of galvanic corrosion. 3. Surface Treatment: Apply a corrosion-resistant treatment to the aluminum sheets. Anodizing is a common surface treatment method that creates a protective oxide layer on the aluminum surface, making it more resistant to corrosion when in contact with concrete. 4. Use Dissimilar Metals: Avoid using dissimilar metals in contact with aluminum sheets and concrete. When dissimilar metals, such as steel or iron, come into contact with aluminum in the presence of moisture, galvanic corrosion is more likely to occur. Therefore, it is best to use aluminum fasteners or supports when working with aluminum sheets and concrete. 5. Proper Drainage: Ensure proper drainage in areas where aluminum sheets are in contact with concrete. Accumulation of water or moisture can accelerate galvanic corrosion. By providing adequate drainage, you can minimize the amount of moisture that comes into contact with the aluminum, reducing the risk of corrosion. 6. Regular Maintenance: Regularly inspect and maintain the aluminum sheets and their protective measures. If any damage or deterioration is observed, promptly repair or replace the barrier coatings, insulation, or surface treatments to ensure continued protection against galvanic corrosion. By implementing these preventive measures, you can significantly reduce the risk of galvanic corrosion when using aluminum sheets with concrete, prolonging the lifespan and integrity of the aluminum and the concrete structures.

- Q: what is aluminum pigment paint in the scratch cards of lottory?is it metalic or organic sabstance like latex?

- Yes its aluminium metal. Finely divided aluminium powder is dispersed in a polymer resin as used for paint.

- Q: im making a presentation and once i read through it it feels like its leading up to something but then goes flat. any ideas. my project ' steel cars compared to aluminium'

- Aluminium is extremely flammable. We use it in thermite welding and as solid rocket fuel. The Emperor Napoleon carried* an aluminium fork while the lower royalty had to make do with gold forks. *In those days people carried their table wear around with them same as we carry our car keys.

- Q: How is aluminum obtained from its ore?

- Aluminum is obtained from its ore through a process called the Bayer process. First, the ore, called bauxite, is crushed and mixed with a solution of sodium hydroxide. This mixture is then heated and pressurized in a digester, causing the aluminum oxide to dissolve and form sodium aluminate. After the impurities are removed, the sodium aluminate solution is cooled and treated with carbon dioxide, which converts it into aluminum hydroxide. Finally, the aluminum hydroxide is heated and transformed into pure aluminum metal through electrolysis.

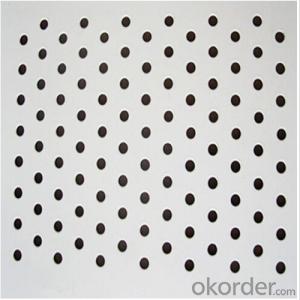

- Q: Can aluminum sheets be perforated?

- Yes, aluminum sheets can be perforated. Perforation is a process that involves creating holes or punctures in a material, and it can be done on various types of metals, including aluminum.

- Q: Which are better? I currently have steel (kinda ugly) rims on my Chevy Blazer right now, and my roommate has some aluminum alloy rims that will fit that he wants to sell me. He hates my steel rims so much that he's willing to sell me the alloy ones for $100.Should I take it? Or just stick with my steel ones?

- A heavier rotating mass is harder on the brakes so the aluminum are better mechanically but they will shatter if you hit a curb or pothole to hard where the steel is malleable . Since you are using this vehicle for personal transportation the pretty aluminum rims will be your best choice . If it were a pick up truck being used for construction I would use the steel . Of course we are really talking extreme hypothetical because either set will do you just fine , we are really talking looks here .

- Q: Are the aluminum sheets suitable for manufacturing power distribution panels?

- Yes, aluminum sheets are suitable for manufacturing power distribution panels. Aluminum is a lightweight and durable material with excellent electrical conductivity, making it ideal for use in power distribution systems. Additionally, it is highly resistant to corrosion, which is crucial for ensuring the longevity and reliability of the panels.

- Q: Can aluminum sheets be laminated with other materials?

- Indeed, it is possible to laminate aluminum sheets with alternative substances. Lamination denotes the fusion of multiple layers of diverse materials, thereby yielding a composite material that possesses heightened qualities. Aluminum sheets can be laminated with a variety of materials, including plastics, fabrics, papers, or other metals, through the utilization of either adhesive bonding or the application of heat and pressure. This process of lamination facilitates the amalgamation of favorable attributes from distinct materials, ultimately yielding a final product that exhibits elevated strength, durability, appearance, or specific functionality. Laminated aluminum sheets find widespread employment in industries such as construction, automotive, aerospace, and packaging, where the amalgamated properties of the laminated substances confer distinct advantages.

Send your message to us

Gold Aluminum Foil Sheets for Decorative Aluminum Roof Panels Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords