GI Sheet Metal Building Material and Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

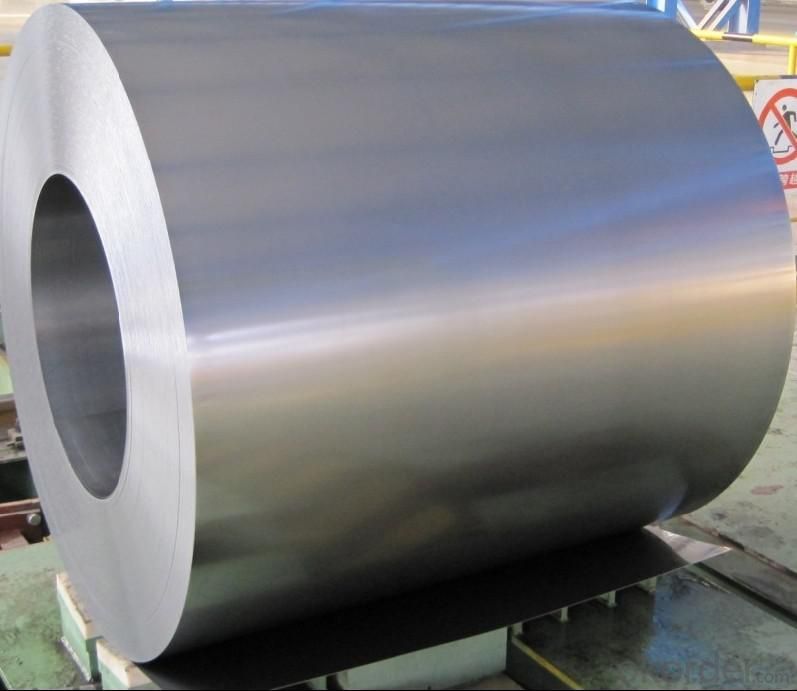

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

| Processability | Yield strength | Elongation % | Elongation % | |

| Common PV | - | 270-500 | - | |

| Mechanical interlocking JY | - | 270-500 | - | |

| Structure JG | >=240 | >=370 | >=18 | |

| Deep drawn SC | - | 270-380 | >=30 | |

| EDDQ SC | - | 270-380 | >=30 |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible.

- Q: How are steel coils coated or painted?

- Steel coils are typically coated or painted using a process called coil coating. In this process, the steel coil is cleaned, treated, and primed before being coated with a layer of paint or a protective coating. This is usually achieved through a continuous automated line, where the coil is unwound, cleaned, coated using various methods such as roller coating or spraying, and then cured to ensure adhesion and durability of the coating. This process allows for efficient and uniform coating application, providing the steel coils with enhanced corrosion resistance and aesthetic appeal.

- Q: What is the purpose of steel coils?

- The purpose of steel coils is to serve as a form of material storage and transportation for various industries. These coils are typically made by winding steel strips into a circular shape, providing a compact and efficient way to store large quantities of steel. Steel coils are used in numerous applications, such as manufacturing, construction, automotive, and appliance industries, where they can be easily transported, processed, and formed into the desired shape for different products.

- Q: i found a similar question asking what metals were in stainless steel but i don't know if they are the same.... they probably aren't.

- steel is iron with a little bit of carbon mixed in. how much carbon determines the hardness of the steel. stainless steel is the same mostly, it has nickle and chromium added in to make it corrosion resistant.

- Q: Can steel coils be coated with anti-fingerprint materials?

- Yes, steel coils can be coated with anti-fingerprint materials. These coatings are designed to minimize fingerprint smudging and make the surface easier to clean, improving the appearance and functionality of the steel coils.

- Q: How are steel coils protected during storage and transportation?

- Steel coils are protected during storage and transportation through various measures. Firstly, they are typically wrapped with a layer of protective material such as plastic or paper to shield them from moisture, dust, and other contaminants. Additionally, steel coils are often stored in a controlled environment, such as a warehouse, to prevent exposure to extreme temperatures and weather conditions. During transportation, they are secured using specialized equipment such as steel coil racks, which prevent movement and minimize the risk of damage. These protective measures ensure the integrity and quality of steel coils throughout their storage and transportation processes.

- Q: How are steel coils used in the production of transportation equipment?

- Steel coils are used in the production of transportation equipment, such as automobiles, ships, and trains, to create various structural components. These coils are typically shaped and formed into parts like chassis, frames, bodies, and panels, providing strength, durability, and stability to the vehicles. Additionally, steel coils can be used in the manufacturing of wheels, axles, and suspension systems, ensuring reliable performance and safety in transportation equipment.

- Q: What are the different types of steel coils?

- There are several different types of steel coils, including hot-rolled coils, cold-rolled coils, galvanized coils, and stainless steel coils.

- Q: I want to know what to my wash stainless fridge door with before applying the stainless steel polish.

- I just use a regular spray on kitchen cleaner like 409. Then after I do that to prevent the streaks, just use baby oil. Put a tiny bit on a paper towel and wipe it over the doors. I learned this from online and from a pal that is in the navy. They can't have streaks on anything for navy inspections.

- Q: I was wondering what kind of company casts and sells steel without acting as a contractor as well. They only sell steel no install it

- If you are talking about raw steel materials and products I believe you are talking about a steel processor and warehouse company or a steel distributor. There are many different points along the steel manufacturing process that you could buy steel products. It would depend on various factors. Depending the amount, type, grade, gauge, properties, origin and a host of other elements you could purchase the steel in billet, plate, diamond plate, rolled sheet (cold or hot), coil, beam, stamped, pickled, scrapped, etc. You get the idea. Now I don't know where you are in the world, but you can go to one of the two sites below, which I have used for product sourcing and research before. The last one is a major manufacturer that I have actually been to. I hope this helps.

- Q: Can steel coils be painted or coated?

- Yes, steel coils can be painted or coated. Painting or coating steel coils is a common practice to enhance their aesthetic appearance, protect them from corrosion, or improve their performance in various applications.

Send your message to us

GI Sheet Metal Building Material and Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords