Galvanized Steel Sheet in Ciols with Prime Quality Best Selling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Galvanized Steel Coil Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

2.Main Features of the Galvanized Steel Coil:

• Base material for countless outdoor and industrial applications

• High corrosion resistance

• High strength

• Good formability

• Rust- proof ability

• Good visual effect

3.Galvanized Steel Coil Images

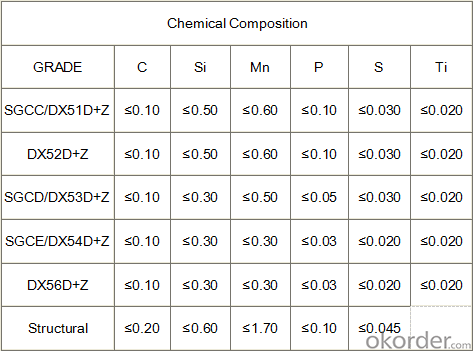

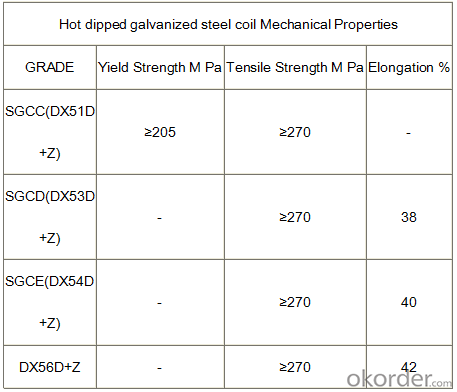

4.Galvanized Steel Coil Specification

Operate Standard: ASTM A653M-04/JIS G3302/DIN EN10143/GBT 2518-2008

Grade : SGCD,SGCH, Q195,DX51D

Zinc coating :40-180g( as required)

Width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

Coil id:508mm/610mm

Coil weight: 4-10 MT(as required)

Surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

5.FAQ of Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

3.How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What are the challenges in the production of steel coils?

- The production process of steel coils encounters several obstacles. Firstly, ensuring consistent quality throughout the process is a major challenge. It is necessary for steel coils to possess uniform thickness, width, and flatness. However, achieving this consistently can prove to be difficult due to variations in raw materials, equipment, and operating conditions. Another hurdle involves effectively managing the intense temperatures involved in the production process. Steel coils are formed by heating steel slabs or billets to extremely high temperatures and subsequently rolling them into coils. Maintaining the necessary temperatures and ensuring proper cooling can be a complex task, as any deviations can result in inconsistencies in the final product. Furthermore, the production of steel coils demands a significant amount of energy. The steel industry ranks among the largest energy consumers worldwide. The constant challenge lies in reducing energy consumption while maintaining production efficiency. To tackle this challenge, the implementation of energy-efficient technologies and process optimization is imperative. Moreover, the production of steel coils generates a substantial amount of waste and emissions. Steel manufacturing involves various chemical reactions that release pollutants such as carbon dioxide, sulfur dioxide, and particulate matter. Meeting environmental regulations and minimizing these emissions are significant challenges for the industry. Additionally, the production of steel coils often involves large quantities, necessitating efficient logistics and transportation systems. Ensuring timely delivery and minimizing damage during transportation can be challenging due to the weight and size of the coils. Lastly, the steel industry confronts market challenges, including fluctuating prices of raw materials, competition from alternative materials, and global economic conditions. Adapting to market demands and maintaining competitiveness are vital for the sustainable production of steel coils. Overall, the challenges in steel coil production encompass maintaining consistent quality, managing high temperatures, reducing energy consumption and emissions, optimizing logistics and transportation, and adapting to market dynamics. Addressing these challenges requires continuous innovation, technological advancements, and a focus on sustainability.

- Q: Can steel coils be coated with organic materials?

- Yes, steel coils can be coated with organic materials. Organic coatings such as paints or varnishes can be applied to steel coils to provide protection against corrosion, improve aesthetics, or add other desired properties.

- Q: What are the quality control measures for steel coil production?

- To ensure that the final product meets the necessary standards and specifications, it is crucial to have quality control measures in place for steel coil production. Here are several commonly used measures in the process: 1. Inspection of Raw Materials: Prior to production, a thorough examination of the chemical composition, mechanical properties, and surface defects of materials like steel billets is conducted. This guarantees that only high-quality materials are used. 2. Control of Processes: Critical parameters such as temperature, rolling speed, tension, and lubrication are continuously monitored and controlled throughout production. Regular checks and adjustments are made to ensure that these parameters fall within the specified tolerances. 3. Assessment of Dimensions and Surfaces: Steel coils undergo stringent inspections to ensure they meet the required thickness, width, and length specifications. Surface defects like scratches, pits, or dents are meticulously examined and minimized to meet quality standards. 4. Mechanical Testing: Regular testing of mechanical properties like tensile strength, yield strength, elongation, and hardness is carried out. These tests are vital in ensuring that the steel coils possess the desired strength and performance characteristics. 5. Visual Inspection: Trained inspectors conduct thorough visual inspections to identify any visible defects or irregularities in the steel coils. Issues such as cracks, corrosion, or uneven surfaces are detected, and necessary actions are taken to rectify or reject faulty coils. 6. Non-Destructive Testing: Methods like ultrasonic testing, magnetic particle testing, or eddy current testing are often employed to detect internal defects like voids, inclusions, or discontinuities that may impact the quality of the steel coils. 7. Documentation and Traceability: Proper documentation and traceability of all quality control measures are maintained throughout the production process. This includes recording test results, inspection reports, and other relevant data to ensure transparency and accountability. 8. Continuous Improvement: Quality control measures in steel coil production are not static but constantly evolving. Regular audits, customer feedback, and analysis of process data are utilized to identify areas for improvement and implement corrective actions to enhance product quality. By implementing these quality control measures, steel coil manufacturers can guarantee that the final product meets the necessary specifications, performs reliably, and achieves customer satisfaction.

- Q: I am doing an assignment for my materials class, im not asking for the answer but just some help. I have the assignment finished and handed in but the teacher gave it back with one comment, he asked me to explain the grain growth in steel during hydraulic press bending. Im completely stuck, please help. Thanks.

- There is such a thing as critical strain which will lead to extraordinary grain growth on annealing;but not without annealing.It would be to do with the density of grain growing sources and clearly the density of these nuclei woul increase with increasing severity of strain so I just of a guess that that those parts of a pressing with least strain might grow most.But I must tell you that in the case of Aluminium alloy extrusions severe and expensive coarse grain occurs near the surface and particularly toward the back end of the bar;so this would be where most severe deformation takes place.However in a pressed steel part you have all possible circumstances,some of which on ironed walls will resemble extrusion,others would be bending strains,tensile and compressive .I have to cop out of this now because as old wasname above,said it depends.But bear in mind that it is unlikely that the material you mention would be hot pressed,further arse grain might only be a surface problem and is likely to be cured by normalising so that new ferrite grows from austenite.A similar solution does't exisat for Al alloy extrusions,it has to be machined off.In a cold steel pressig you would only expect to see a cold worked sructure because the recrystallisation temperature of pressable steel would not be less than,say 550 degrees C .

- Q: How are steel coils used in the production of railway tracks?

- Steel coils are used in the production of railway tracks as they provide the raw material for manufacturing the rails. The steel coils are first processed and shaped into long, straight rails through various processes such as rolling and heat treatment. These rails are then laid and joined together to form the railway tracks, providing a sturdy and durable foundation for trains to run on.

- Q: How are steel coils used in the production of automotive parts?

- Steel coils are used in the production of automotive parts as they serve as the primary raw material for manufacturing various components such as body panels, chassis, and structural parts. These coils are processed through different techniques like cutting, stamping, and welding to shape and form the desired parts. The strength and durability of steel make it an ideal material for automotive applications, ensuring the safety and performance of vehicles.

- Q: How are steel coils protected from extreme weather conditions?

- Steel coils are typically protected from extreme weather conditions using various methods such as covering them with waterproof wraps, storing them in climate-controlled warehouses, or applying anti-corrosion coatings. These measures ensure that the coils are shielded from moisture, temperature fluctuations, and other environmental factors that could potentially damage or degrade the steel.

- Q: engineering sloutions related to steel fabrication

- The American Institute of Steel Construction develops codes for steel building design in the U.S. See the link to below to the Steel Solutions Center at their website. You can find free programs for designing structural steel elements from clicking on technical resources at that link. Most of the programs presume that you are a structural/civil engineer with knowledge of the steel design specifications.

- Q: The length of a steel beam increases by 0.78 mm when its temperature is raised from 22 degrees C to 35 degrees C. What is the length of the beam at 22 degrees C (in meters)?I used: L = (0.78 mm)/[(9/5)(.00000645 F)(13)] = 5.17 meters but Mastering Physics said Not quite. Check through your calculations; you may have made a rounding error or used the wrong number of significant figures. I'm confused because this is how we learned this kind of problem in class, so if anybody knows what I did wrong, feel free to correct my errors! Thanks

- we may use the formula ΔL=α(Lo)(Tf-To) where Lf is the length of steel at temp. Tf Lo is length at To α is the coefficient of linear expansion of steel which is 11x10^-6/°C ΔL=0.78mm (the change in length) Lo=? ΔL=α(Lo)(Tf-To) Lo=ΔL/[α(Tf-To)] Lo=(0.78x10^-3m)/[(11x10^-6/°C)(35°C-2...? Lo=5.455m answer

- Q: What are the different types of steel coil surface protection methods?

- There are several types of steel coil surface protection methods, including oiling, painting, galvanizing, and applying protective films. These methods help prevent corrosion, rusting, and damage to the steel surface during storage, transportation, and processing.

Send your message to us

Galvanized Steel Sheet in Ciols with Prime Quality Best Selling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords