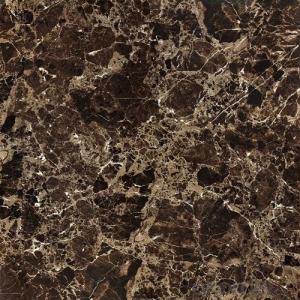

Full Polished Glazed Porcelain Tile 600 YDL6BB101

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1267.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

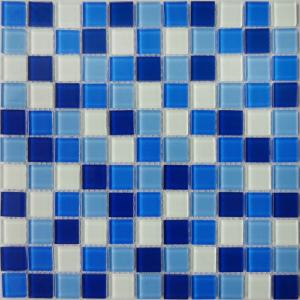

You Might Also Like

Product Brief Introduction

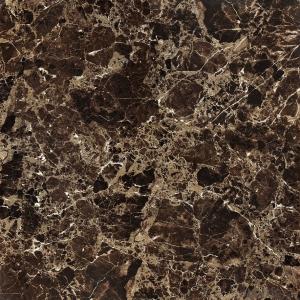

Full Polished Glazed Porcelain Tile 600 YDL6BB101 is one of the most popular color of Crystal Jade Serie, which is one serie of Polished Porcelain Tile in the present market. Just like other series, it could be used for interior floor for apartment, villa, super market as well as other public areas.

Product Features

Polished Porcelain Tile, Double Loading

Only Grade AAA available

Strict control on color shade, deformation, anti-pollution, surface glossy degree as well as packing

Competitive price

Standard export packing: Pater Carton+ Wooden Pallet

Fast delivery

OEM service could be offered

Marketing support on samples, catalogues as well as carton designing

Professional sales team for product, document and schedule of importing and exporting.

1) Available in many designs, specifications and assorted color,unique designs and exclusive quality

2) Used for indoor & outdoor wall and floordecorations, as well as Stair Case Product;

3) Easy to install, anti-dust, washable, acid-proof,alkali-proof, durable

Product Specification

Tile Type: Polished Porcelain Tile

Quality standard: GB/T4100-2006, ISO13006, ISO9001

Water Absorption Rate: 《0.5%

Breaking Strength: 》 1800 N

Rupture Modulus: 》40 MPa

Length and Width Tolerance: ±0.1%

Surface Smoothness: ±0.15%

Edge Straightness: ±0.15%

Wearing Strength: 《1600 mm3

Glossiness: 》 85 Degree

Resistance to Chemical: Class UA

Resistance to Staining: Class 3.

Packing Information (For 27.5 Tons heavy 20’Fcl)

For 600x600mm, 4pcs/Ctn, 40 Ctns/Pallet, 960 Ctns/20’Fcl, 1382.4m2/20’Fcl

For 800x800mm, 3pcs/Ctn, 28 Ctns/Pallet, 616 Ctns/20’Fcl, 1182.72m2/20’Fcl

Production Line & Package

FAQ

1. For Polished Porcelain Tile, is the 30*60 available?

—— Yes, 30*60 is available. Due to the basic size is 60*60, we need to cut 60*60 tile into 30*60. 6 pcs are packed into one carton.

2. What is the MOQ for this tile?

—— Normally the MOQ is 1382.4 m2 for one 20’ container. To support our clients, we could go with 3 models to fill one container at most.

3. Can we use the carton with our own design and brand name?

—— Yes. Normally we go with Neutral Carton or our Carton with our CMAX brand name. But for carton of client’s own design, the MOQ for one size is 5 containers, due to the carton factory can’t arrange production if quantity is below 5000 pcs.

- Q: Ok, the builder and an independent foundation company both say that no foundation damage happened, just some settlement. What should I do with these cracks on tiles and on walls. Would leaving them alone cause any problem? When and how should I fix those?

- Cracked tiles, if there are no sharp edges won t cause a problem but should be fixed if you have spare tiles. Wall s you don t describe exactly what type of crack so no one can help there to much.. If its the wall board thats cracked that can be a big job. If its a corner crack there are a couple ways to do this. Tiles ( if you have or can get extra) can be pulled out, the area cleaned and tiles put back in. Any questions you can e mail me through my avatar. GL .

- Q: We are planning small home improvements during the next year to prepare our house for sale. I would like to switch out our 4 year old formica countertop and replace it with granite tile. A slab is out of the question due to cost. We have a small kitchen and would need about 40 tiles. When I looked on the internet for costs, it seems I can get these tiles for under $300.00? Does that sound right, I think that‘s less than what we paid for the Formica. Also, my next question is can you use the same tile for the entryway, which is next to the kitchen, or it that a little too much of the same thing?

- The tile will be cheaper, using a slab is always more expensive. Remember that the tile doesn't include the installation cost either. You can use it in the entryway just remember that granite is very slippery when used as flooring and caution must be taken. To get the best look out of granite tile for the countertop ensure that they are laid with very little grout space. Ensure you hire a good experienced tile setter one that has laid granite tile. You want them to ensure that the edges all have the finished edge. This will give you the best look, it's really not a big deal for an experienced installer. Don't use a wood edge and go for the tile, it will last longer and increase the value of your home more than formica. You can often find bullnose edge pieces to lay with your tile unless you are buying a rare granite.

- Q: I have a new bathtub with Durock cement board installed around it and I‘m ready for tile. I just got a guy out to give me an estimate for doing the tile work around the tub and he said the Durock would have to be primed first. I‘ve heard you‘re supposed to put the tile directly on the Durock, not paint it. Now I don‘t know what to do. Is he wrong? If he‘s wrong, do I hire someone else or just question him? He did another (non-tile related) job for me and did an excellent job, so I trust him, but I‘m nervous about this. Any advice is appreciated. Thanks!

- I don't see how priming it would have any advantage. I tiled over some a couple years ago and have had no problems at all. I would think the adhesion would be in question if you are basically adding a layer of paint in between. You don't prime concrete before you lay tile flooring so why would you do otherwise to a cement board? I would ask him for is reasoning behind it. If it sounds like BS and a way to add some time to the job hire someone else.

- Q: How to paste tiles better

- Fight color processing. The contrast of the tiles gives a strong first impression. Usually in white or other light-colored tone, for the color of the tile color slightly deeper, and with the flowers and decorative lines of color is commensurate, such as white lining blue, beige with light brown and so on. Fight the color of the method can be in the waist below the lining of another slightly darker color; also available two-color tile to play the grid, the specific spelling to see the personal mind.

- Q: We have a hardwood floor in our bathroom, and because it gets too damp, we want to install vinyl tiles on top of the hardwood floor. But I cannot imagine vinyl sticking to wood - can it be done successfully? Any glue tips??

- If you put a vinyl tile on a hard wood weather you varnish it or seal it or any thing, The lines in the hardwood will telescope through and show right through the vinyl in no time.. Plus the natural expansion and contraction of wood will break the glue bond of the vinyl Any flooring questions you can e mail me through my avatar GL

- Q: I want to remove really ugly ceramic tiles from my bathroom walls. I want to do this without destroying the plaster wall underneath. What‘s the best way to take them off? Is this going to be a big job? Thanks in advance!!

- Do it very carefully. Use a flat edged mason's chisel and hammer. Lay the chisel against the wall or as close to the wall as possible. Tap on the head with a hammer until the tile comes loose. No matter how hard you try, you are going to knock some plaster loose. It is a lot of work.

- Q: Can you lay down those adhesive floor tiles on top of existing tiles? If so, what kind of prep do you need to do to make sure they stick properly. I‘m not sure what type of tiles are in place now, but they are similiar to the types used in schools and other institutions. Very cheap, flexible, and bland. I want to lay something down in place of them, but don‘t want to rip them up. Is that possible? Thanks!

- I've seen it done before. You have to make sure the floor is super clean, not little bumps or crusty stuff for sure. Then, don't line the tiles up directly on top of the old ones, but offset them instead. The stick down tiles will last for a while, but the ones that were in the bathroom at my old house peeled up after only 1 year cause of the water.

- Q: is it correct if i divide 198 by 2.25= 88 tiles? help ty

- What's the dimensions for the tiles? Cm? M? Km? mm?

- Q: I believe the tiles were made in Mexico. They are light beige in color. They were installed in the master bathroom which has a shower stall, no bathtub.

- Seal them now. After time it doesn't matter what color the grout is it will start to discolor from dirt. By sealing it now you prevent that. It makes it easier to clean also. Read the directions on the can or bottle to see how often you have to reapply. DO NOT USE BLEACH ON YOUR FLOORS!!! It will eat away at the sealer.

- Q: I installed tile couple of days ago in my shower. I was wondering isn't it better to put bathroom caulking instead of grout since it is flexible and it will last longer and provide better water resistance. Does grout make tile stronger or is caulking only applied on edges? Would I make mistake if I used bathroom caulking between tiles? Thanks

- Grout Vs Caulk

Send your message to us

Full Polished Glazed Porcelain Tile 600 YDL6BB101

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1267.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches