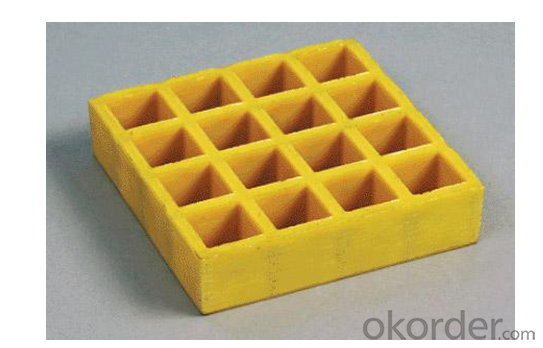

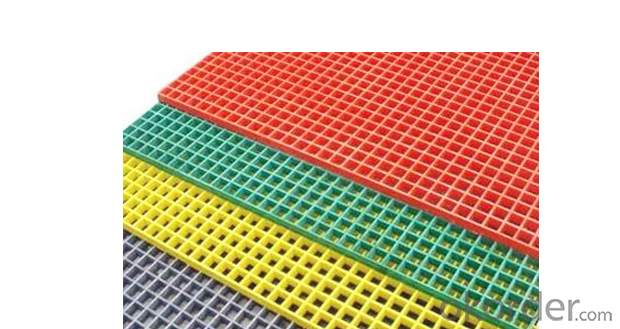

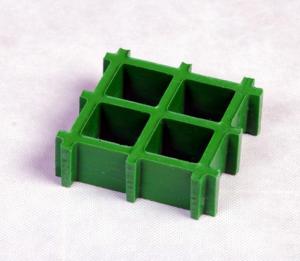

FRP Pultrusion Profiles Molded Gratings in Various Colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Light Weight & High Strength

Safety & Anti-slip

Electrical Insulating

Aging Resistance

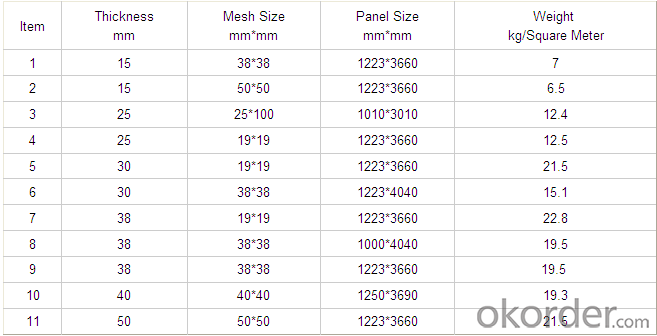

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

no maintenance

- easy installation

Application

- In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

Pool railings in sewage treatment industry

Corrosive chemical industry equipment around the fence

All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

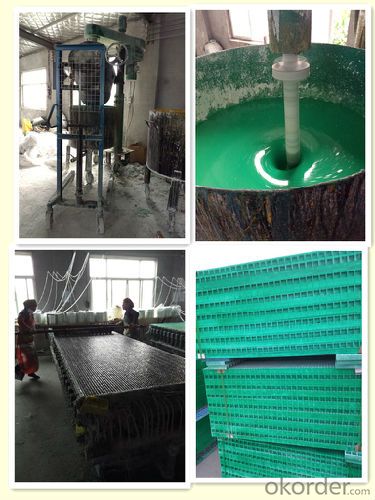

FACTORY

- Q: Are FRP pultrusion profiles resistant to seismic activity?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high strength-to-weight ratio and excellent mechanical properties. However, when it comes to seismic activity, their resistance depends on various factors. In general, FRP pultrusion profiles can exhibit good resistance to seismic activity due to their inherent properties. The composite materials used in their construction, such as fiberglass and resin, offer high tensile strength and stiffness, making them capable of withstanding dynamic loads caused by earthquakes. Moreover, FRP pultrusion profiles have been extensively tested and proven to possess excellent fatigue resistance. This property is crucial during seismic events as structures are subjected to repeated dynamic loading. The ability of FRP profiles to withstand cyclic loading without suffering from fatigue failure significantly enhances their seismic resistance compared to traditional materials like steel or concrete. Another advantage of FRP pultrusion profiles in seismic activity is their lightweight nature. Their low weight reduces the overall mass of the structure, resulting in lower seismic forces. This weight reduction can lead to reduced seismic responses and less damage during an earthquake. However, it is important to note that the seismic resistance of FRP pultrusion profiles can be influenced by various factors. These include the design and quality of the profiles, the connection details, and the overall structural system in which they are used. Proper engineering and design considerations must be taken into account to ensure optimal performance and seismic resistance. In conclusion, FRP pultrusion profiles have the potential to offer good resistance to seismic activity due to their high strength, stiffness, and fatigue resistance. However, their performance in seismic events depends on various factors, and careful design and engineering practices are essential to maximize their seismic resistance.

- Q: How do FRP pultrusion profiles perform in earthquake-prone areas?

- FRP (Fiber Reinforced Polymer) pultrusion profiles have several advantages when it comes to performance in earthquake-prone areas. Firstly, FRP pultrusion profiles are known for their high strength-to-weight ratio. This means that they are lightweight compared to traditional construction materials such as steel or concrete, while still offering significant strength. This characteristic plays a crucial role in earthquake-prone areas as it reduces the overall mass of the structure, minimizing the inertial forces that can be generated during seismic events. Therefore, FRP profiles can effectively withstand and absorb the energy released during an earthquake, reducing the risk of structural damage or collapse. Additionally, FRP pultrusion profiles have excellent durability and resistance to corrosion. Unlike steel, they are not susceptible to rust or other forms of degradation caused by moisture or chemicals commonly found in earthquake-prone areas. This resistance to corrosion ensures the long-term performance and reliability of FRP profiles, minimizing the need for costly maintenance and repairs. Moreover, FRP pultrusion profiles exhibit high flexibility and ductility. These characteristics allow them to deform and absorb energy without fracturing or breaking, which is particularly advantageous during seismic events. By dissipating the energy generated by the earthquake, FRP profiles help to protect the integrity of the structure and prevent catastrophic failures. Lastly, FRP pultrusion profiles are non-conductive materials, meaning they do not conduct electricity. This feature is important in earthquake-prone areas where electrical infrastructure can be vulnerable to damage. The non-conductive nature of FRP profiles reduces the risk of electrical faults or fires caused by seismic activity. In conclusion, FRP pultrusion profiles offer several performance advantages in earthquake-prone areas. Their lightweight, high strength, durability, flexibility, and non-conductive properties make them a reliable and effective choice for construction in regions prone to seismic activity.

- Q: Can FRP pultrusion profiles be used for structural applications?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can definitely be used for structural applications. Pultrusion is a manufacturing process that creates continuous, reinforced profiles by pulling fiber reinforcements through a resin bath and then through a heated die to cure the resin. This process results in strong, lightweight, and corrosion-resistant profiles that have excellent mechanical properties. FRP pultrusion profiles are widely used in various structural applications due to their high strength-to-weight ratio. These profiles can be engineered to have specific load-bearing capacities, stiffness, and durability, making them suitable for a range of structural requirements. Some common structural applications for FRP pultrusion profiles include bridges, walkways, platforms, handrails, supports, beams, columns, and reinforcements in concrete structures. They are also used in applications where traditional materials like steel or wood are not suitable due to corrosion, electrical conductivity, or weight concerns. FRP pultrusion profiles offer several advantages over traditional materials. They are lightweight, which makes them easier to handle and transport. Additionally, they are resistant to corrosion, chemicals, and UV radiation, providing long-term durability even in harsh environments. Moreover, they have excellent dimensional stability, meaning they do not warp, twist, or shrink over time. In conclusion, FRP pultrusion profiles are highly suitable for structural applications due to their strength, lightweight nature, corrosion resistance, and durability. They offer a cost-effective alternative to traditional materials while providing superior performance in various structural projects.

- Q: Can not use glass steel support column, the main support for the door

- 1, glass steel toughness and carrying impact performance is strong, but the rigidity is relatively poor, that is, tensile, impact resistance is better, compressive performance is poor, so it is not suitable for props and other components.2, toughened glass is completely transparent, visual art, and the vertical stiffness is very large, excellent compressive strength, can be customized according to the needs of the processing of different thickness, if used to support the weight is not a big door can, but need to have the steel frame (outsourcing stainless steel).

- Q: Can FRP pultrusion profiles be used in wastewater treatment facilities?

- Indeed, FRP pultrusion profiles have the capability to be utilized in wastewater treatment facilities. These profiles possess numerous benefits, including a high strength-to-weight ratio, resistance to corrosion, and durability, all of which make them highly suitable for the challenging conditions found in such facilities. In wastewater treatment facilities, there exists a wide range of applications where FRP pultrusion profiles can be effectively employed. These applications encompass walkways, handrails, ladders, grating, and structural supports, among others. The corrosion resistance of FRP makes it particularly well-suited for deployment in areas that are exposed to moisture and the chemicals present in wastewater. Furthermore, the lightweight nature of FRP profiles simplifies the installation process and reduces the burden placed on supporting structures. The durability of FRP pultrusion profiles guarantees long-term performance, even in aggressive environments. They exhibit a remarkable resistance to chemical attacks, UV radiation, and bacterial growth, rendering them highly appropriate for wastewater treatment applications. Additionally, FRP profiles can be tailored to meet specific load requirements and can be easily fabricated to accommodate various shapes and sizes. Furthermore, FRP pultrusion profiles possess outstanding electrical insulation properties, which can prove advantageous in wastewater treatment facilities where electrical safety is of utmost concern. To summarize, FRP pultrusion profiles can be effectively employed in wastewater treatment facilities due to their corrosion resistance, durability, lightweight nature, and versatility in terms of design and fabrication. These profiles provide long-lasting solutions for a variety of applications within these facilities, ensuring operational efficiency and minimizing maintenance needs.

- Q: Are FRP pultrusion profiles resistant to oils and greases?

- Yes, FRP pultrusion profiles are generally resistant to oils and greases. The combination of fiberglass reinforcement and resin matrix in FRP pultrusions provides excellent resistance to various chemicals, including oils and greases. This makes them suitable for applications where exposure to oils and greases is expected.

- Q: Are FRP pultrusion profiles resistant to caustic solutions?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to caustic solutions. The combination of the reinforcing fibers and the polymer matrix used in FRP pultrusion provide excellent chemical resistance. Caustic solutions, such as strong alkaline substances, can often corrode or degrade traditional materials like steel or wood. However, FRP pultrusion profiles are highly resistant to chemical attack, making them suitable for applications where exposure to caustic solutions is common. This resistance makes FRP pultrusion profiles an ideal choice for industries such as chemical processing, wastewater treatment, and marine environments where corrosive substances are present. Nonetheless, it is important to consult the manufacturer's specifications and guidelines to ensure that specific caustic solutions are compatible with the particular FRP pultrusion profile being used.

- Q: Are FRP pultrusion profiles resistant to termites?

- Yes, FRP pultrusion profiles are resistant to termites. Due to their composition of fiberglass and resin, they are not a food source for termites and are therefore not susceptible to termite damage.

- Q: Can FRP pultrusion profiles be used in modular construction?

- Certainly, FRP (Fiber Reinforced Polymer) pultrusion profiles are a viable option for integration into modular construction. These profiles possess advantageous qualities, including a lightweight composition, exceptional strength, resistance to corrosion, and superb thermal and electrical insulating properties. These attributes make them an ideal choice for implementation in modular construction, where the focus is on prefabrication, transportation, and swift assembly. The utilization of FRP pultrusion profiles within modular construction yields numerous benefits. Firstly, their lightweight nature facilitates easy handling and transport, which consequently reduces logistical costs and effort. Secondly, their high strength-to-weight ratio ensures structural integrity without adding unnecessary weight to the modular components. This is especially advantageous in scenarios where weight reduction is critical, such as rooftop installations or areas with limited load-bearing capacity. Moreover, the corrosion resistance of FRP profiles eliminates the necessity for regular maintenance and enhances the longevity of the modular construction. This proves particularly advantageous in challenging environments, like coastal regions or chemical processing facilities, where traditional construction materials like steel may rapidly deteriorate. Furthermore, FRP pultrusion profiles can be easily tailored to fulfill specific design requirements. They can be manufactured in diverse shapes, sizes, and colors, granting flexibility in modular construction design. Additionally, these profiles can be seamlessly integrated with other construction materials, such as concrete or wood, ensuring compatibility with existing modular systems. To summarize, the lightweight nature, high strength, corrosion resistance, and customization capabilities of FRP pultrusion profiles make them highly suitable for modular construction. Their implementation in this field improves efficiency, reduces costs, and enhances the overall performance and durability of modular buildings and structures.

- Q: What are the mechanical properties of FRP pultrusion profiles?

- FRP (Fiber Reinforced Polymer) pultrusion profiles possess several desirable mechanical properties that make them a popular choice in various industries. Some of the key mechanical properties of FRP pultrusion profiles include: 1. High Strength: FRP pultrusion profiles exhibit exceptional tensile and flexural strength, making them suitable for applications requiring load-bearing capabilities. The reinforcing fibers, such as carbon, glass, or aramid, provide the profiles with superior strength-to-weight ratios compared to traditional materials like steel or aluminum. 2. Lightweight: FRP pultrusion profiles are significantly lighter than metals, resulting in reduced transportation and installation costs. The low weight also makes them easier to handle and manipulate during construction or manufacturing processes. 3. Corrosion Resistance: Unlike metals, FRP pultrusion profiles are inherently corrosion-resistant. They do not rust, corrode, or degrade when exposed to harsh environments, including moisture, chemicals, or UV radiation. This property makes them ideal for applications in marine, chemical, and infrastructure industries. 4. Dimensional Stability: FRP pultrusion profiles offer excellent dimensional stability, meaning they retain their shape and size even under extreme temperature variations. They have minimal thermal expansion and contraction rates, ensuring long-term structural integrity. 5. Electrical Non-Conductivity: FRP profiles are non-conductive and possess excellent electrical insulation properties. This property is crucial in applications where electrical conductivity must be avoided, such as in electrical enclosures or infrastructure near power lines. 6. Design Flexibility: FRP pultrusion profiles can be manufactured in various complex shapes and sizes, allowing for customized designs to meet specific application requirements. They can be easily molded or formed during the manufacturing process, making them adaptable to diverse project needs. 7. Impact Resistance: FRP pultrusion profiles exhibit good impact resistance, absorbing and dispersing energy when subjected to mechanical loads. This property ensures durability and structural integrity, making them suitable for applications prone to impact or dynamic loading, such as construction, transportation, or sporting equipment. Overall, the mechanical properties of FRP pultrusion profiles make them an attractive alternative to traditional materials in a wide range of industries, offering strength, durability, and corrosion resistance while being lightweight and easy to work with.

Send your message to us

FRP Pultrusion Profiles Molded Gratings in Various Colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords