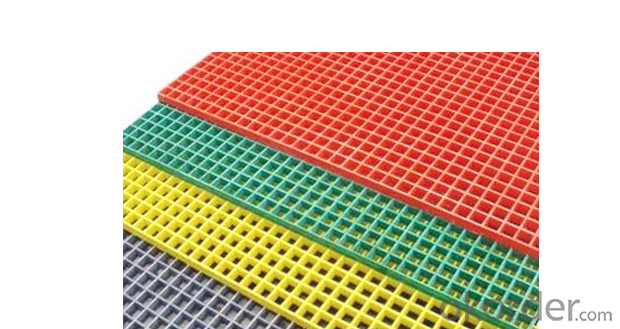

FRP Pultrusion Profiles for Walkway - Popular Color, Best Quality FRP Grating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

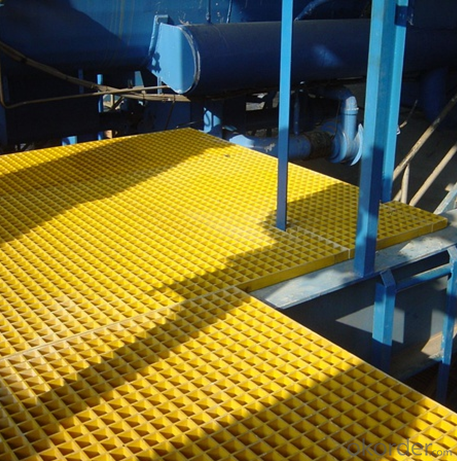

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

l Corrosion Resistance

l Fire Resistance

l Light Weight & High Strength

l Safety & Anti-slip

l Electrical Insulating

l Aging Resistance

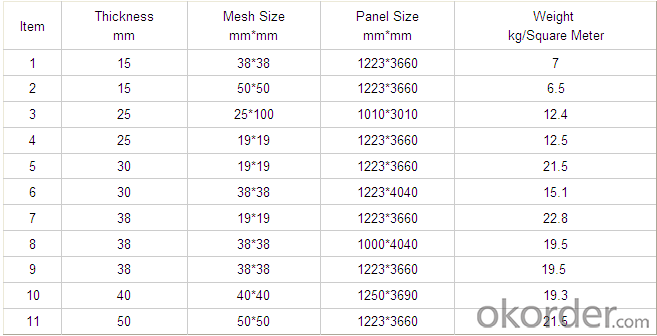

Specification

Advantage

1) coated with prevent aging layer

2) excellent insulating performance

3) no maintenance

4) high strength

5) long service life

6) easy installation

Application

l Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

l In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

l Pool railings in sewage treatment industry

l Corrosive chemical industry equipment around the fence

l All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

4. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

5. How is the package?

Usually, we arrange the standard out-package for exporting.

PROCESS

FACTORY

- Q: What are the typical applications for FRP pultrusion profiles?

- FRP pultrusion profiles have a wide range of uses in different industries. In construction, they are commonly used for structural components like beams, columns, and platforms. These profiles have a high strength-to-weight ratio, are corrosion resistant, and durable, making them perfect for long-lasting, low-maintenance infrastructure. In transportation, FRP pultrusion profiles are used to manufacture lightweight components for buses, trucks, railcars, and wind turbines. Their lightweight nature helps reduce fuel consumption and increase energy efficiency. Additionally, they can withstand chemicals, moisture, and UV radiation, ensuring their durability in harsh environments. In the electrical and power distribution field, FRP pultrusion profiles are utilized for manufacturing insulating supports, cable trays, and ladder racks. These profiles offer excellent electrical insulation properties, making them a safe and reliable choice for electrical installations. Furthermore, their non-conductive nature helps prevent electrical accidents and eliminates the risk of electric shock. In the marine industry, FRP pultrusion profiles are ideal for manufacturing boat hulls, decks, and other marine components due to their resistance to saltwater corrosion. Their high strength and stiffness enable them to withstand the tough conditions of the marine environment. Additionally, FRP pultrusion profiles are used in the chemical processing industry for manufacturing tanks, pipes, and platforms. They are resistant to various chemicals and corrosive substances, ensuring the equipment's integrity and enhancing safety in chemical plants. Overall, FRP pultrusion profiles have diverse applications in industries such as construction, transportation, electrical, marine, and chemical processing. Their unique properties make them a versatile and dependable choice for various structural and functional needs.

- Q: Are FRP pultrusion profiles resistant to chemicals used in semiconductor manufacturing?

- Yes, FRP pultrusion profiles are highly resistant to the chemicals typically used in semiconductor manufacturing. The composite materials used in FRP profiles have excellent chemical resistance, making them ideal for withstanding the corrosive effects of various chemicals used in this industry.

- Q: Are FRP pultrusion profiles resistant to earthquakes?

- FRP pultrusion profiles have inherent properties that make them resistant to earthquakes. The composite material used in these profiles offers high strength and stiffness, allowing them to withstand seismic forces and vibrations. Additionally, FRP is lightweight, which reduces the load on structures during an earthquake. However, it is important to note that the overall seismic resistance of a structure depends on various factors, including design, installation, and the specific application of the pultrusion profiles. Therefore, proper engineering and design considerations are crucial to ensure optimal earthquake resistance.

- Q: Can FRP pultrusion profiles be used in the construction of safety barriers?

- Yes, FRP pultrusion profiles can be used in the construction of safety barriers. FRP (Fiber Reinforced Polymer) pultrusion profiles offer high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for safety barrier applications. They can withstand harsh environmental conditions and provide excellent impact resistance, making them an ideal choice for ensuring safety in various industries such as construction, transportation, and infrastructure.

- Q: How do FRP pultrusion profiles compare to steel or aluminum profiles?

- FRP (Fiber Reinforced Polymer) pultrusion profiles offer several advantages over steel or aluminum profiles. Firstly, FRP profiles are extremely lightweight, making them easier to handle and install. This is particularly beneficial in industries where weight reduction is crucial, such as aerospace or automotive applications. Another significant advantage of FRP pultrusion profiles is their exceptional corrosion resistance. Unlike steel or aluminum, FRP does not rust or corrode when exposed to moisture, chemicals, or harsh environmental conditions. This property makes FRP profiles ideal for applications in marine environments or chemical processing plants, where traditional materials would quickly deteriorate. In terms of strength, FRP pultrusion profiles can match or even surpass steel or aluminum profiles. The unique combination of reinforcing fibers and polymer resin in FRP provides excellent tensile and flexural strength. Additionally, FRP profiles have a high stiffness-to-weight ratio, meaning they can withstand heavy loads while remaining lightweight. Furthermore, FRP pultrusion profiles offer excellent electrical insulation properties. Unlike metal profiles, FRP does not conduct electricity, making it a safe choice for electrical applications where insulation is crucial. While steel or aluminum profiles may have their own advantages in certain applications, FRP pultrusion profiles often provide a more cost-effective solution due to their long lifespan and low maintenance requirements. FRP profiles are not susceptible to rust, corrosion, or degradation, minimizing the need for frequent repairs or replacements. Overall, FRP pultrusion profiles offer a compelling alternative to steel or aluminum profiles, providing lightweight, corrosion-resistant, strong, and electrically insulating solutions for various industries and applications.

- Q: Are FRP pultrusion profiles resistant to ultraviolet radiation?

- Yes, FRP pultrusion profiles are generally resistant to ultraviolet radiation. The combination of the composite material and the resin used in pultrusion manufacturing provides excellent UV resistance, making them suitable for outdoor applications.

- Q: Can FRP pultrusion profiles be used in the construction of recreational vehicles (RVs)?

- Yes, FRP pultrusion profiles can be used in the construction of recreational vehicles (RVs). These profiles offer several advantages such as high strength-to-weight ratio, resistance to corrosion and rot, and excellent thermal insulation properties. Additionally, FRP pultrusion profiles can be easily molded into complex shapes, making them suitable for various applications within the construction of RVs, including structural components, flooring, walls, and roofs.

- Q: Are FRP pultrusion profiles resistant to fungal growth?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to fungal growth. The composite materials used in pultrusion, such as resins and fibers, are inherently resistant to biological degradation, including fungal attack. The non-porous nature of FRP pultrusion profiles also makes it difficult for fungi to penetrate and grow on the surface. Additionally, the manufacturing process of pultrusion involves curing the composite materials at high temperatures, which further enhances their resistance to fungal growth. However, it is important to note that no material is completely immune to fungal growth under all conditions. Factors such as high humidity, prolonged exposure to moisture, and poor maintenance practices may still contribute to fungal growth on FRP pultrusion profiles, although to a lesser extent compared to other materials like wood or metal. Regular inspection and proper cleaning can help maintain the fungal resistance of FRP pultrusion profiles over their lifespan.

- Q: Are FRP pultrusion profiles fire resistant?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are fire resistant. The combination of the reinforcing fibers and the polymer matrix used in FRP pultrusion profiles provide them with excellent fire resistance properties. These profiles are manufactured using a process known as pultrusion, which involves impregnating reinforcing fibers such as fiberglass or carbon fiber with a thermosetting resin. This resin undergoes a curing process, resulting in a strong and durable composite material. One of the key advantages of FRP pultrusion profiles is their inherent fire resistance. The thermosetting resin used in the manufacturing process has properties that make it highly resistant to fire. When exposed to flames or high temperatures, the resin does not melt or burn easily, thus preventing the spread of fire. Additionally, the reinforcing fibers in FRP profiles also contribute to their fire resistance. Fiberglass, for example, is an inorganic material that does not burn. It acts as a barrier against heat transfer and helps to minimize the spread of flames. Furthermore, FRP pultrusion profiles can be engineered to meet specific fire safety standards and regulations. By incorporating additional fire retardant additives or using specialized resin systems, the fire resistance of these profiles can be further enhanced. It is important to note that while FRP pultrusion profiles are fire resistant, their exact fire rating may vary depending on the specific composition and design. Therefore, it is essential to consult with manufacturers or suppliers who can provide detailed information about the fire resistance properties of their FRP pultrusion profiles.

- Q: Are FRP pultrusion profiles resistant to hydrochloric acid?

- FRP pultrusion profiles exhibit a general resistance to hydrochloric acid. The corrosion resistance of FRP materials varies based on the specific resin and fiber used during manufacturing. Nevertheless, most FRP pultrusion profiles are designed to endure exposure to a wide array of chemicals, including hydrochloric acid. The corrosion resistance of FRP is attributed to the chemical inertness of the resin matrix, typically composed of polyester, vinyl ester, or epoxy. These resins form a protective barrier against chemical attack, allowing FRP profiles to maintain their structural integrity even in harsh surroundings. However, the level of resistance may fluctuate depending on the concentration and temperature of the hydrochloric acid. In instances of high concentration or elevated temperatures, the resistance may diminish. It is always recommended to refer to the manufacturer's specifications or seek expert advice to ensure the suitability of FRP pultrusion profiles for specific acid concentrations and temperature ranges. In conclusion, FRP pultrusion profiles are renowned for their exceptional chemical resistance and are frequently selected for applications involving exposure to acids or corrosive environments.

Send your message to us

FRP Pultrusion Profiles for Walkway - Popular Color, Best Quality FRP Grating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords