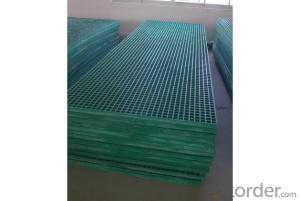

FRP Pultrusion Profiles Grating for Walkway with Various Colors & Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Light Weight & High Strength

Safety & Anti-slip

Electrical Insulating

Aging Resistance

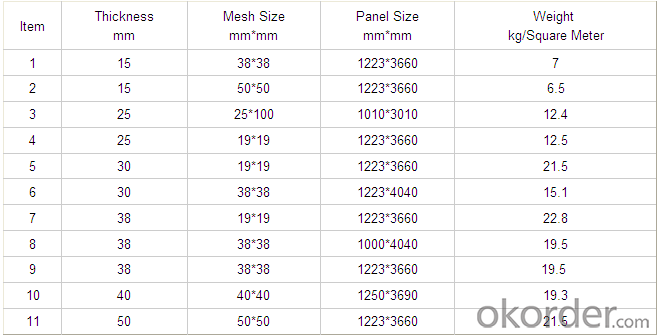

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

- Pool railings in sewage treatment industry

Corrosive chemical industry equipment around the fence

All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

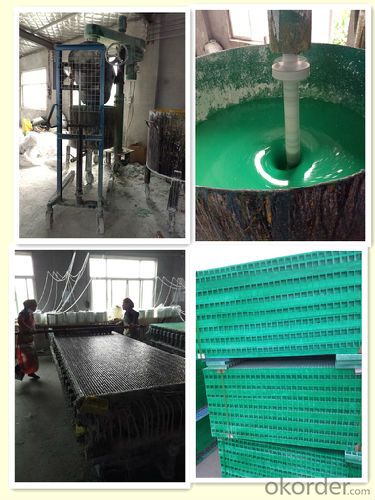

PROCESS

FACTORY

- Q: Can FRP pultrusion profiles be used in the construction of stadium seating?

- Yes, FRP pultrusion profiles can be used in the construction of stadium seating. FRP (Fiber Reinforced Polymer) pultrusion profiles offer high strength, durability, and corrosion resistance, making them a suitable choice for stadium seating applications. These profiles can be customized to meet specific design requirements and provide a lightweight alternative to traditional materials like steel or concrete.

- Q: How do FRP pultrusion profiles perform in corrosive gas environments?

- In environments with corrosive gases, FRP pultrusion profiles exhibit outstanding performance. Their exceptional corrosion resistance, a notable characteristic of FRP, makes them highly suitable for applications that involve exposure to corrosive gases. Typically composed of a combination of glass fibers and a resin matrix like polyester or vinyl ester, FRP pultrusion profiles inherently possess corrosion resistance and do not react with most corrosive gases. Consequently, they can endure exposure to a wide range of corrosive gases, including sulfur dioxide, hydrogen sulfide, chlorine, and others. Furthermore, FRP pultrusion profiles excel in durability and long-term performance within corrosive gas environments. Unlike traditional materials such as steel or aluminum, they do not rust, corrode, or degrade over time. This corrosion resistance ensures the structural integrity of FRP profiles, even in harsh environments, thereby reducing maintenance and replacement costs. Moreover, FRP pultrusion profiles can be customized by incorporating specific chemical-resistant resins and additives. This customization allows for tailoring the FRP profiles to precisely meet the requirements of the application, ensuring optimal performance and longevity. In conclusion, FRP pultrusion profiles present an exceptional choice for environments with corrosive gases due to their remarkable corrosion resistance, long-term durability, and customization capabilities. They offer a reliable and cost-effective solution for industries such as chemical processing, oil and gas, wastewater treatment, and others in which exposure to corrosive gases is a concern.

- Q: Can FRP pultrusion profiles be used in the construction of railway sleepers?

- The use of FRP (Fiber Reinforced Polymer) pultrusion profiles is indeed possible in the construction of railway sleepers. These profiles possess a range of advantages that render them suitable for this particular application. To begin with, the lightweight yet robust nature of FRP pultrusion profiles makes them an ideal option for railway sleepers. They boast high strength-to-weight ratios, enabling them to withstand heavy loads and reliably support the weight of trains. Moreover, their lightweight constitution facilitates transportation and installation, thereby reducing construction time and costs. Additionally, FRP pultrusion profiles exhibit a high resistance to corrosion, a crucial aspect for railway sleepers. Unlike traditional materials such as wood or steel that are prone to corrosion when exposed to moisture and chemicals, FRP profiles are non-corrosive. Consequently, they do not necessitate regular maintenance or replacement due to rust or decay. Furthermore, these profiles offer exceptional durability and longevity. They can withstand UV radiation, extreme temperatures, and chemicals, ensuring a longer lifespan compared to conventional materials. As a result, the need for frequent replacements is minimized, leading to reduced maintenance and lifecycle costs. Moreover, FRP pultrusion profiles can be tailored to meet specific design requirements. They can be manufactured in various shapes and sizes to accommodate different railway sleeper designs, providing flexibility in construction. Additionally, they can be produced in different colors, allowing for aesthetic customization. Lastly, FRP pultrusion profiles possess excellent electrical insulation properties, a critical factor for railway sleepers. They are capable of providing insulation between the train tracks and the ground, preventing electrical interference and ensuring safe operation. In conclusion, FRP pultrusion profiles are a suitable choice for constructing railway sleepers due to their lightweight yet strong composition, corrosion resistance, durability, customization options, and electrical insulation properties.

- Q: How do FRP pultrusion profiles perform in high-temperature applications?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their excellent performance in high-temperature applications. The combination of the reinforcement fibers and the polymer matrix used in the pultrusion process results in a material that exhibits superior thermal stability and resistance. One of the key advantages of FRP pultrusion profiles in high-temperature applications is their ability to withstand elevated temperatures without losing structural integrity. Unlike traditional materials like steel or aluminum, which may experience deformation or failure under high temperatures, FRP pultrusion profiles maintain their shape and performance. The specific performance of FRP pultrusion profiles in high-temperature applications depends on the choice of reinforcement fibers and the polymer matrix used. Different fibers, such as glass, carbon, or aramid, have varying thermal resistance properties. By selecting the appropriate fiber type and resin system, manufacturers can tailor the FRP pultrusion profiles to withstand specific temperature ranges. FRP pultrusion profiles are also known for their low thermal conductivity, which means they do not conduct heat as efficiently as metals. This property makes them suitable for insulation applications, as they can help minimize heat transfer and maintain a stable temperature environment. Moreover, FRP pultrusion profiles are resistant to corrosion, which is particularly advantageous in high-temperature environments where metals can corrode more rapidly. Their corrosion resistance ensures long-term durability and reduces maintenance requirements. In summary, FRP pultrusion profiles excel in high-temperature applications due to their structural integrity, thermal stability, low thermal conductivity, and corrosion resistance. Manufacturers can customize the material composition to meet specific temperature requirements, making FRP pultrusion profiles a reliable choice for a range of industries, including aerospace, automotive, chemical processing, and oil and gas.

- Q: Are FRP pultrusion profiles resistant to chemicals used in oil refineries?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to chemicals used in oil refineries. The composition of FRP profiles includes a combination of high-strength fibers, such as fiberglass, carbon fibers, or aramid fibers, embedded in a polymer resin matrix. This unique construction provides excellent resistance to a wide range of chemicals, including those commonly found in oil refineries. The polymer resin matrix used in FRP profiles can be carefully selected to withstand harsh chemical environments. For instance, vinyl ester or epoxy resins are often used in the manufacturing of FRP profiles for oil refinery applications due to their superior chemical resistance properties. Moreover, FRP pultrusion profiles are inherently corrosion-resistant, unlike traditional materials like steel or concrete, which can deteriorate when exposed to aggressive chemicals found in oil refineries. This corrosion resistance ensures the long-term durability and reliability of FRP profiles in such environments. Additionally, FRP profiles offer several other advantages in oil refinery applications, including high strength-to-weight ratio, electrical insulation, non-magnetic properties, and ease of installation. These characteristics make FRP pultrusion profiles an ideal choice for various structural, piping, and equipment applications within oil refineries. However, it is essential to consider the specific chemicals and concentrations involved in a particular oil refinery application. While FRP profiles generally exhibit excellent resistance to a wide range of chemicals, there might be certain highly concentrated or specialized chemicals that could potentially affect their performance. In such cases, it is advisable to consult with FRP manufacturers or experts who can provide tailored solutions to meet the specific chemical resistance requirements of the oil refinery.

- Q: Can FRP pultrusion profiles be used in the construction of recreational vehicles (RVs)?

- Yes, FRP pultrusion profiles can be used in the construction of recreational vehicles (RVs). These profiles offer several advantages such as high strength-to-weight ratio, resistance to corrosion and rot, and excellent thermal insulation properties. Additionally, FRP pultrusion profiles can be easily molded into complex shapes, making them suitable for various applications within the construction of RVs, including structural components, flooring, walls, and roofs.

- Q: Can FRP pultrusion profiles be used in electrical insulation applications?

- Yes, FRP pultrusion profiles can be used in electrical insulation applications. FRP (Fiber Reinforced Polymer) materials have excellent electrical insulation properties, making them suitable for a wide range of electrical applications. The pultrusion process ensures that the profiles have uniform insulation properties and high strength, making them ideal for use in electrical insulation applications.

- Q: Can FRP pultrusion profiles be used in aerospace applications?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can be used in aerospace applications. FRP materials have several advantages that make them suitable for aerospace use. Firstly, they have excellent strength-to-weight ratios, which is crucial in the aerospace industry to reduce weight and enhance fuel efficiency. Secondly, FRP materials exhibit high corrosion resistance, making them suitable for prolonged exposure to harsh environments, such as high altitude and extreme temperatures. Additionally, FRP pultrusion profiles offer design flexibility, allowing for complex shapes and geometries to be manufactured. This flexibility enables aerospace engineers to tailor the profiles to specific requirements and optimize performance. Furthermore, FRP materials have low thermal conductivity, which helps in insulation applications and reducing heat transfer. Lastly, FRP pultrusion profiles have demonstrated good fatigue resistance, which is essential for aerospace applications subjected to cyclic loading. Overall, these properties make FRP pultrusion profiles a viable choice for various aerospace components, including structural members, interior parts, and electrical enclosures.

- Q: How do FRP pultrusion profiles handle bending and flexing?

- FRP pultrusion profiles are designed to handle bending and flexing exceptionally well due to their inherent structural properties. The combination of reinforcing fibers, such as fiberglass, and a polymer resin matrix in the pultruded profiles results in high strength and stiffness. This allows the profiles to withstand bending forces without any significant deformation or failure. Additionally, the ability of FRP to withstand flexing is attributed to its high fatigue resistance, making it suitable for applications that require repeated bending or flexing movements.

- Q: Can FRP pultrusion profiles be used in walkway systems?

- Yes, FRP pultrusion profiles can be used in walkway systems. FRP pultrusion profiles are lightweight, strong, and resistant to corrosion, making them suitable for use in various applications, including walkways. They offer durability, low maintenance, and can withstand heavy loads, making them a reliable choice for walkway systems.

Send your message to us

FRP Pultrusion Profiles Grating for Walkway with Various Colors & Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords