FRP Pultrusion Profiles Yellow Color FRP Gratings for Walkway

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 30000 m2 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

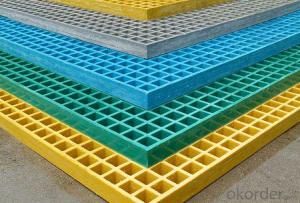

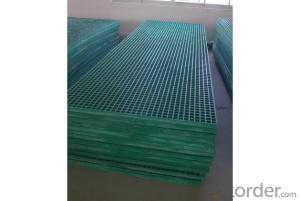

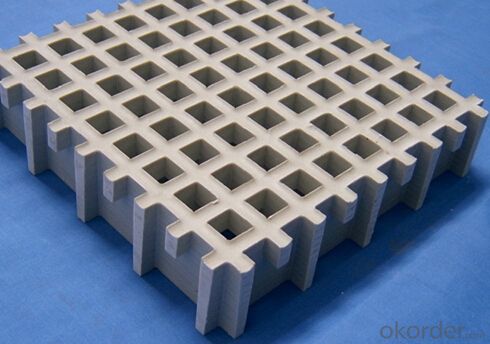

Product description of FRP Grating

FRP Grating, Molded FRP Grating, Fiberglass Grating, GRP Grating,GRP Molded Grating,FRP Pultrusion Grating, FRP Mini Mesh Grating,Trench Grating, Drain Grating,Grating Walkway, Platform Grating...

Comparing with other floor materials, FRP molded grating provides a series of benefits, unmatched impact resistance,

while the strength-weight-ratio is only one-fourth of that of steel grating. It is easy to cut and install.

Specification of FRP Grating

Item | Thickness mm | Mesh Size mm*mm | Panel Size mm*mm | Weight kg/Square Meter |

01 | 15 | 38*38 | 1223*3660 | 7 |

02 | 15 | 50*50 | 1223*3660 | 6.5 |

03 | 25 | 25*100 | 1010*3010 | 12.4 |

04 | 25 | 19*19 | 1223*3660 | 12.5 |

05 | 30 | 19*19 | 1223*3660 | 21.5 |

06 | 30 | 38*38 | 1223*4040 | 15.1 |

07 | 38 | 19*19 | 1223*3660 | 22.8 |

08 | 38 | 38*38 | 1000*4040 | 19.5 |

09 | 38 | 38*38 | 1223*3660 | 19.5 |

10 | 40 | 40*40 | 1250*3690 | 19.3 |

11 | 50 | 50*50 | 1223*3660 | 21.5 |

Images

Features

1.Corrosion and Chemical resistant

2.Slip-resistant

3.High strength-to-weight ratio

4.Ergonomic

5.Low maintenance

6.Fire retardant

7.Easily fabricated and installed

FAQ:

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. Payment terms?

We can accept L/C, T/T etc.

- Q: Are FRP pultrusion profiles resistant to jet fuel?

- Yes, FRP pultrusion profiles are generally resistant to jet fuel.

- Q: Can FRP pultrusion profiles be used in the construction of water treatment plants?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of water treatment plants. FRP pultrusion profiles have several advantages that make them suitable for this application. Firstly, FRP pultrusion profiles are corrosion-resistant. Water treatment plants are exposed to various corrosive elements, such as chemicals and moisture. Traditional materials like steel and concrete can deteriorate over time due to corrosion, leading to maintenance issues and potential structural failures. However, FRP pultrusion profiles are highly resistant to corrosion, ensuring long-term durability and reducing maintenance costs. Secondly, FRP pultrusion profiles are lightweight and have high strength-to-weight ratios. This makes them easy to handle and transport while maintaining structural integrity. Water treatment plants often require structural elements that can withstand heavy loads and support equipment. FRP pultrusion profiles provide the necessary strength without adding excessive weight, making them an ideal choice for such applications. Additionally, FRP pultrusion profiles are non-conductive and have excellent electrical insulation properties. This can be crucial in water treatment plants, where electrical equipment and wiring are present. The non-conductive nature of FRP helps prevent electrical hazards and ensures safe operation. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements. They can be manufactured in various shapes and sizes, allowing for flexibility in design and construction. This adaptability makes FRP pultrusion profiles suitable for a wide range of applications within water treatment plants, including structural supports, walkways, handrails, and equipment enclosures. In summary, FRP pultrusion profiles are an excellent choice for the construction of water treatment plants due to their corrosion resistance, lightweight yet strong nature, electrical insulation properties, and customization options. They offer long-lasting durability, reduced maintenance costs, and enhanced safety, making them a reliable and efficient solution for this critical infrastructure.

- Q: Can FRP pultrusion profiles be used in the water treatment industry?

- Indeed, the water treatment industry can make use of FRP pultrusion profiles. These profiles, made of Fiber Reinforced Polymer, are widely recognized for their exceptional resistance to corrosion, impressive strength, and long-lasting durability. These qualities render them highly appropriate for a diverse range of applications within the water treatment field. In particular, FRP pultrusion profiles can be employed in the construction of water treatment tanks, pipes, and other crucial infrastructure. They exhibit remarkable resistance to chemicals, including those commonly employed in water treatment procedures. This resistance to corrosion ensures that equipment enjoys an extended lifespan and maintenance costs are minimized. Moreover, FRP pultrusion profiles boast an impressive strength-to-weight ratio, making them an ideal choice for applications that necessitate lightweight yet robust materials. This quality facilitates the easier installation and transportation of water treatment equipment. Furthermore, the flexibility in design offered by FRP pultrusion profiles is worth noting. Such profiles can be manufactured in a wide array of shapes and sizes to cater to specific project requirements. This capability allows for the customization and optimization of water treatment systems, guaranteeing the efficiency and effectiveness of water treatment processes. In summary, FRP pultrusion profiles present themselves as a dependable and cost-effective option for the water treatment industry. Their excellent resistance to corrosion, exceptional strength, and design flexibility make them highly suitable for numerous applications within water treatment systems.

- Q: Can FRP pultrusion profiles be used in the telecommunications and data communication industry?

- Indeed, the telecommunications and data communication industry can utilize FRP (Fiber Reinforced Plastic) pultrusion profiles. These profiles possess numerous advantages that render them appropriate for incorporation in this particular sector. First and foremost, FRP pultrusion profiles exhibit exceptional electrical insulation properties, rendering them perfect for applications in the telecommunications and data communication industry where minimizing electrical conductivity is imperative. FRP profiles do not conduct electricity, thereby ensuring the absence of interference or grounding issues that could potentially disrupt data transmission. Secondly, FRP pultrusion profiles are both lightweight and robust, resulting in a high strength-to-weight ratio. This characteristic makes them well-suited for the construction of communication towers, antenna supports, and satellite dish mountings. In these applications, the profiles must withstand environmental stresses such as wind loads. Moreover, FRP profiles exhibit outstanding corrosion resistance, a crucial attribute in the telecommunications and data communication industry where equipment is frequently exposed to harsh outdoor environments. Unlike traditional materials like steel or aluminum, FRP profiles do not rust or corrode, thereby guaranteeing the longevity and reliability of the infrastructure. Furthermore, FRP profiles can be easily customized and manufactured in various shapes and sizes to meet the precise requirements of telecommunications and data communication applications. This flexibility enables the design and construction of intricate structures capable of accommodating different equipment and technologies. In summary, FRP pultrusion profiles provide a multitude of advantages that render them highly suitable for application in the telecommunications and data communication industry. Their electrical insulation properties, lightweight yet strong nature, corrosion resistance, and design flexibility make them a dependable choice for supporting infrastructure in this sector.

- Q: What is the tensile strength of FRP pultrusion profiles?

- The tensile strength of FRP pultrusion profiles can vary depending on the specific composition and manufacturing process. However, it is generally known that FRP pultrusion profiles have high tensile strength, often exceeding that of traditional materials like steel.

- Q: Can FRP pultrusion profiles be used in the construction of solar panel frames?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of solar panel frames. FRP pultrusion profiles are lightweight, strong, and resistant to corrosion, making them an ideal material choice for solar panel frames. The durability and high strength-to-weight ratio of FRP pultrusion profiles ensure that the frames can withstand various weather conditions and long-term exposure to sunlight. Additionally, FRP pultrusion profiles can be easily customized to meet specific design requirements, allowing for flexibility in the construction of solar panel frames. Overall, the use of FRP pultrusion profiles in solar panel frame construction offers numerous advantages, making it a suitable choice for the solar energy industry.

- Q: Are FRP pultrusion profiles resistant to wear or abrasion?

- Yes, FRP pultrusion profiles are highly resistant to wear and abrasion. The combination of strong reinforcing fibers and a durable resin matrix makes them capable of withstanding harsh conditions and maintaining their structural integrity over time, even in high-stress environments. This resistance to wear and abrasion makes FRP pultrusion profiles an excellent choice for applications that require long-lasting and low-maintenance solutions.

- Q: How do FRP pultrusion profiles compare to traditional building materials?

- FRP (Fiber Reinforced Polymer) pultrusion profiles offer several advantages over traditional building materials. Firstly, FRP profiles are extremely lightweight yet highly durable, making them ideal for applications where weight reduction is critical, such as in aerospace or automotive industries. In contrast, traditional materials like steel or wood are much heavier and may require additional support or reinforcement. Another key advantage of FRP pultrusion profiles is their exceptional strength-to-weight ratio. They possess high tensile and flexural strength, surpassing that of many traditional materials. This strength allows FRP profiles to provide excellent structural support while minimizing the overall weight of the structure. Furthermore, FRP pultrusion profiles are corrosion-resistant, making them suitable for environments prone to moisture, chemicals, or extreme temperatures. Unlike steel or wood, FRP does not rust or rot, hence requiring minimal maintenance and extending the lifespan of the structure. In terms of design flexibility, FRP profiles offer a wide range of shapes and sizes, enabling architects and engineers to create complex and intricate structures. Traditional materials often have limitations in terms of design possibilities and may require additional fabrication steps to achieve the desired shape. Additionally, FRP pultrusion profiles are electrically non-conductive, making them an ideal choice for applications where electrical insulation is required. Unlike metals, FRP does not conduct electricity, reducing the risk of electrical accidents. Lastly, FRP profiles are environmentally friendly as they can be made from recycled materials and are fully recyclable themselves. In contrast, traditional materials like steel or concrete require significant energy consumption and contribute to carbon emissions during their production. Overall, FRP pultrusion profiles offer numerous advantages over traditional building materials, including lightweight, high strength, corrosion resistance, design flexibility, electrical insulation, and environmental sustainability. These benefits make FRP profiles a compelling choice for a wide range of industries and applications.

- Q: Can FRP pultrusion profiles be used in the construction of chemical processing equipment?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can be used in the construction of chemical processing equipment. FRP offers excellent resistance to corrosion, chemicals, and high temperatures, making it a suitable material for such applications. The pultrusion process ensures that the profiles are strong, durable, and have consistent properties, making them reliable for use in chemical processing equipment where resistance to corrosive substances is crucial.

- Q: Can FRP pultrusion profiles be used in modular construction?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can definitely be used in modular construction. FRP profiles are lightweight, high-strength, corrosion-resistant, and have excellent thermal and electrical insulating properties. These characteristics make them ideal for use in modular construction, where the emphasis is on prefabrication, transportation, and rapid assembly. The use of FRP pultrusion profiles in modular construction offers several advantages. First, their lightweight nature makes them easy to handle and transport, reducing logistical costs and effort. Second, their high strength-to-weight ratio ensures structural integrity while minimizing the overall weight of the modular components. This is particularly beneficial in applications where weight reduction is crucial, such as rooftop installations or areas with limited load-bearing capacity. Furthermore, the corrosion resistance of FRP profiles eliminates the need for regular maintenance and extends the lifespan of the modular construction. This is particularly advantageous in harsh environments, such as coastal areas or chemical processing facilities, where traditional construction materials like steel may deteriorate quickly. Additionally, FRP pultrusion profiles can be easily customized to meet specific design requirements. They can be manufactured in various shapes, sizes, and colors, allowing for flexibility in modular construction design. The profiles can also be easily integrated with other construction materials, such as concrete or wood, providing compatibility with existing modular systems. In summary, FRP pultrusion profiles are highly suitable for modular construction due to their lightweight, high strength, corrosion resistance, and customization capabilities. Their use in modular construction can enhance efficiency, reduce costs, and improve the overall performance and durability of modular buildings and structures.

Send your message to us

FRP Pultrusion Profiles Yellow Color FRP Gratings for Walkway

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 30000 m2 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords