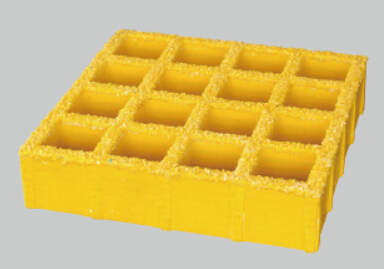

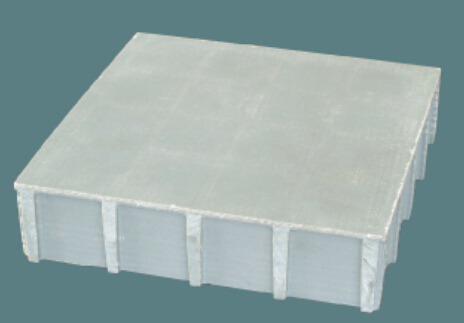

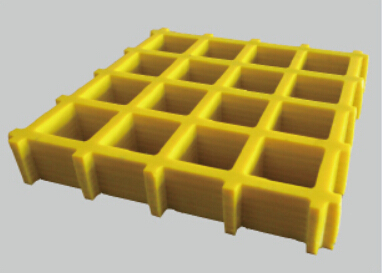

FRP Pultrusion Profiles for High Durable Corrosion Resistant Cesspit Grating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

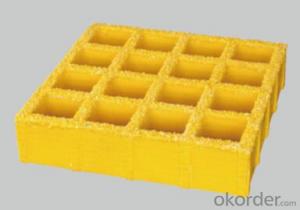

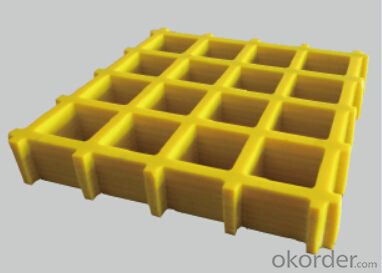

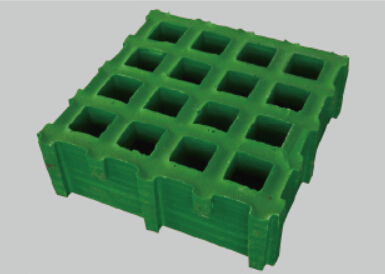

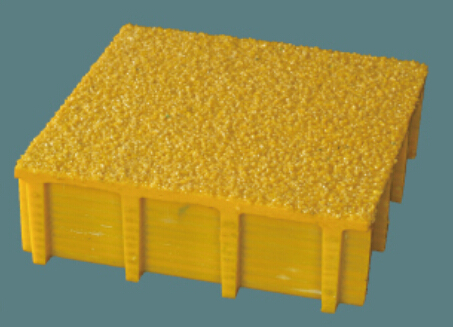

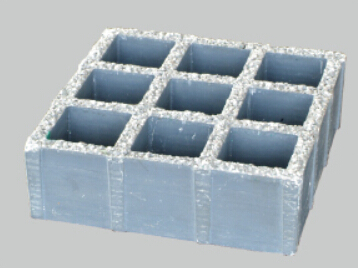

FRP molded grating made of vertical and horizontal continuous fiberglass fully soaked in unsaturated polyester resin giving perfect bi-directional mechanical properties. Combining unmatched corrosion resistance with strength, long life and safety, molded grating provide the ultimate in reliable performance, even in the most demanding corrosive conditions. Besides, it is easy to cut and install. CNBM offer the widest selection with panel sizes, colors and slip resistant surfaces, clients can avail FRP grating your specific requirements.

Product Features:

- Light but high loaded strength

- High anti-corrosion and anti-aging

- Easy installation and maintenance

- Low maintenance

- Non-conductive

- Lowest in life cycle cost

- Corrosion Resstance

- Anti-slippery

- Various sizes and color available

Colour Design:

To satisfy customer's design project, CNBM grating offers a wide selection of grating colors to choose from. The standard colors available for fiberglass grating as following:

- Blue

- Red

- Yellow

- Green

- Light Grey

- Dark Grey

Custom colors of fiberglass grating may be available upon request, you can contact us learn more.

- Q: Can FRP pultrusion profiles be used in the construction of offshore platforms?

- FRP pultrusion profiles have the capability to be utilized in the construction of offshore platforms. These profiles possess a range of beneficial characteristics that render them appropriate for offshore applications. To begin with, FRP pultrusion profiles exhibit a combination of lightness and strength, which is vital for withstanding the harsh environmental conditions encountered by offshore platforms, such as strong winds, waves, and corrosive saltwater. The high strength-to-weight ratio of FRP makes it an optimal choice for reducing overall weight while preserving structural integrity. Moreover, FRP is exceptionally resistant to corrosion, unlike conventional construction materials like steel. This is particularly crucial in offshore environments where metal structures can rapidly corrode due to exposure to saltwater. FRP pultrusion profiles remain unaffected by rust or corrosion, resulting in extended service life and diminished maintenance costs. Additionally, FRP pultrusion profiles possess the capability to be designed and manufactured with exceptional fire resistance properties. This is of utmost importance for offshore platforms, as fire incidents can lead to catastrophic consequences. FRP materials can be engineered to satisfy specific fire safety standards, providing an additional layer of protection. Furthermore, FRP pultrusion profiles offer design flexibility, as they can be easily tailored to meet individual project requirements. This allows for the creation of intricate shapes and sizes, facilitating efficient construction and installation of offshore platforms. In conclusion, the lightweight, corrosion-resistant, fire-resistant, and customizable nature of FRP pultrusion profiles deems them an appropriate choice for constructing offshore platforms. They offer numerous advantages over traditional materials, contributing to enhanced safety, durability, and cost-effectiveness in offshore construction projects.

- Q: Can FRP pultrusion profiles be used for structural applications?

- Certainly, FRP pultrusion profiles can be utilized for structural purposes. The process of pultrusion involves pulling fiber reinforcements through a resin bath and a heated die to cure the resin, resulting in robust, lightweight, and corrosion-resistant profiles with exceptional mechanical properties. The high strength-to-weight ratio of FRP pultrusion profiles makes them widely employed in different structural applications. These profiles can be engineered to possess specific load-bearing capacities, stiffness, and durability, making them suitable for a wide range of structural requirements. FRP pultrusion profiles find common use in various structural applications such as bridges, walkways, platforms, handrails, supports, beams, columns, and reinforcements in concrete structures. They are particularly advantageous in situations where traditional materials like steel or wood are unsuitable due to concerns regarding corrosion, electrical conductivity, or weight. The benefits of FRP pultrusion profiles are numerous. They are lightweight, making them easy to handle and transport. Furthermore, they exhibit resistance to corrosion, chemicals, and UV radiation, ensuring long-term durability even in harsh environments. Additionally, they possess excellent dimensional stability, remaining unaffected by warping, twisting, or shrinking over time. To summarize, FRP pultrusion profiles are highly suitable for structural applications owing to their strength, lightweight nature, corrosion resistance, and durability. They provide a cost-effective alternative to traditional materials while delivering superior performance in various structural projects.

- Q: Are FRP pultrusion profiles resistant to wear or abrasion?

- FRP pultrusion profiles exhibit exceptional durability against wear and abrasion due to the integration of reinforcing fibers, predominantly glass or carbon, and a plastic resin matrix. This combination results in a highly robust material that can endure rigorous utilization. Moreover, the pultrusion process guarantees a uniform composition, with fibers uniformly dispersed throughout the profile, thereby augmenting its resistance to wear and abrasion. Furthermore, FRP pultrusion profiles can be customized with specific additives or surface treatments to further heighten their ability to withstand wear and abrasion, rendering them suitable for diverse applications across industries such as construction, transportation, and marine.

- Q: Can FRP pultrusion profiles be used in the agricultural and farming industry?

- Absolutely, FRP pultrusion profiles are indeed applicable in the agricultural and farming sector. Recognized for their exceptional strength, durability, and corrosion resistance, these profiles are highly suitable for outdoor and challenging environments typically found in this industry. A variety of agricultural and farming applications can benefit from these profiles, including: 1. Fencing and enclosures: By employing FRP pultrusion profiles, strong and enduring fences, gates, and enclosures can be created for safeguarding livestock and crops. These profiles possess resistance against rot, rust, and insect damage, ensuring reliable protection for animals and crops. 2. Structural components: Agricultural buildings, sheds, and greenhouses can utilize FRP pultrusion profiles as structural components. Thanks to their impressive strength-to-weight ratio, lightweight and durable structures can be constructed, capable of withstanding extreme weather conditions. 3. Irrigation systems: FRP pultrusion profiles can be harnessed for the construction of irrigation systems, including pipes, channels, and culverts. These profiles are non-corrosive with a smooth interior surface, reducing friction and improving water flow efficiency. 4. Equipment support and framing: Various agricultural equipment, such as conveyors, platforms, and machinery, can benefit from the support and framing provided by FRP pultrusion profiles. Their superior strength and stiffness make them suitable for heavy-duty applications. 5. Animal housing and equipment: Animal housing and equipment, such as pens, stalls, and feeding troughs, can be constructed using FRP pultrusion profiles. These profiles offer resistance against chemicals, moisture, and UV radiation, resulting in a long lifespan and low maintenance requirements. In conclusion, the outstanding mechanical properties, resistance to environmental factors, and versatility offered by FRP pultrusion profiles make them an excellent choice for the agricultural and farming industry.

- Q: Are FRP pultrusion profiles resistant to electrical surges or lightning strikes?

- FRP pultrusion profiles have inherent electrical insulation properties due to their composition of fiberglass reinforcement and resin matrix. This insulation makes them resistant to electrical surges and lightning strikes to some extent. However, it is important to note that no material can provide absolute protection against extremely high voltage electrical surges or direct lightning strikes. In such cases, additional measures like grounding and lightning protection systems are necessary to ensure the safety of structures or equipment. Therefore, while FRP pultrusion profiles offer some level of resistance to electrical surges and lightning strikes, it is advisable to consult with experts and adhere to relevant safety standards when designing and installing electrical systems in areas prone to such events.

- Q: How do FRP pultrusion profiles withstand extreme temperatures?

- FRP pultrusion profiles are able to withstand extreme temperatures due to the inherent properties of the materials used in their construction. The combination of reinforced fibers, such as fiberglass, and a thermosetting resin matrix creates a composite material with high thermal stability. This enables the profiles to maintain their structural integrity and dimensional stability even under extreme heat or cold conditions. Additionally, the design and manufacturing process of FRP pultrusion profiles ensures that the materials are evenly distributed and tightly bonded, further enhancing their ability to withstand temperature variations without compromising their strength.

- Q: Are FRP pultrusion profiles resistant to oil or fuel spills?

- Yes, FRP pultrusion profiles have inherent resistance to oil and fuel spills. The combination of the fiberglass reinforcement and the resin matrix used in their construction make them highly resistant to the corrosive effects of oil and fuel, making them a suitable choice for applications where exposure to such spills is expected.

- Q: Are FRP pultrusion profiles resistant to automotive fluids?

- Yes, FRP pultrusion profiles are generally resistant to automotive fluids. The inherent chemical resistance and durability of the fiberglass-reinforced plastic make it suitable for withstanding exposure to various automotive fluids such as oils, fuels, and coolants. However, it is essential to consider the specific type of fluid and consult the manufacturer's guidelines to ensure the optimal performance and longevity of the FRP profiles in automotive applications.

- Q: Can FRP pultrusion profiles be used in the construction industry?

- Yes, FRP pultrusion profiles can be used in the construction industry. FRP (Fiber Reinforced Polymer) pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability. These profiles can be used in various construction applications such as structural support systems, window and door frames, bridge components, and building facades. They provide a lightweight and cost-effective alternative to traditional construction materials like steel and concrete.

- Q: Can FRP pultrusion profiles be used in the aerospace and aviation industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the aerospace and aviation industry. FRP pultrusion profiles offer exceptional strength-to-weight ratio, corrosion resistance, and design flexibility, making them suitable for various applications in this industry. One of the key advantages of FRP pultrusion profiles is their high strength-to-weight ratio. This means that they can provide the required structural integrity while keeping the weight of the components low, which is crucial in aerospace and aviation applications where weight reduction is a priority. The lightweight nature of FRP profiles can contribute to fuel efficiency, improved performance, and increased payload capacity. Additionally, FRP pultrusion profiles exhibit excellent resistance to corrosion, including resistance to chemicals, moisture, and UV radiation. This makes them highly suitable for use in aircraft and aerospace systems, where exposure to harsh environmental conditions is common. Unlike traditional metallic materials, FRP profiles can withstand corrosive agents and maintain their structural integrity for extended periods, reducing maintenance requirements and enhancing the durability of aircraft components. Furthermore, the design flexibility of FRP pultrusion profiles allows for the creation of complex shapes and geometries, enabling engineers to tailor the profiles to meet specific requirements. This versatility in design opens up opportunities for innovative solutions in aerospace and aviation applications, such as structural components, aircraft interiors, radomes, fairings, and more. It is worth mentioning that FRP pultrusion profiles have been successfully used in the aerospace and aviation industry for various applications, including wing spars, stabilizers, galleys, interior panels, and cargo containers. Their proven track record demonstrates their reliability and performance in demanding environments. Overall, FRP pultrusion profiles are well-suited for use in the aerospace and aviation industry due to their high strength-to-weight ratio, corrosion resistance, and design flexibility. Their use can contribute to lighter, more efficient, and durable aircraft components, making them a viable choice for various applications in this sector.

Send your message to us

FRP Pultrusion Profiles for High Durable Corrosion Resistant Cesspit Grating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords