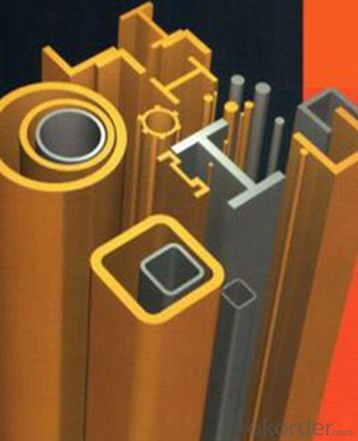

Latest Style FRP Pultrusion Profiles with Anti-Corrosion for Pultruded Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 34 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

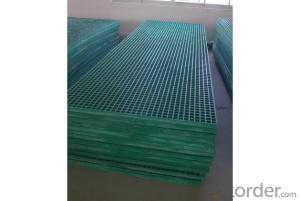

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

SPECIFICATION

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin, VE resin, Phenol resin

Color choice: Yellow, gray, green, custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper.

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk,

foot bridge,

equipment safety fence,

scaffold.

COMPANT DESCRIPTION

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce FRP machines and FRP products.

2.Q:If can customized by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarantee?

A:Gurantee is one year.

5.Q:If you can training?

A:yes ,we can training in our factory also can send engineers to your factory training.

PICTURES

- Q: Can FRP pultrusion profiles be used in agricultural structures?

- Yes, FRP pultrusion profiles can certainly be used in agricultural structures. They offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various applications in the agricultural industry. These profiles can be used in structures like greenhouse frames, livestock enclosures, support beams, fencing, and other agricultural infrastructure.

- Q: Can FRP pultrusion profiles be used for structural applications?

- Yes, FRP pultrusion profiles can be used for structural applications. They are commonly utilized in various industries such as construction, automotive, aerospace, and marine. FRP pultrusion profiles offer high strength-to-weight ratio, excellent corrosion resistance, and durability, making them suitable for structural components like beams, columns, and trusses. Additionally, they can be designed to meet specific load requirements and offer design flexibility.

- Q: Can FRP pultrusion profiles be used in the construction of wastewater treatment tanks?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be effectively used in the construction of wastewater treatment tanks. FRP pultrusion profiles are known for their high strength-to-weight ratio, corrosion resistance, and durability, making them an ideal choice for applications in harsh environments such as wastewater treatment facilities. FRP pultrusion profiles are made by pulling continuous fibers, typically glass or carbon, through a resin bath and then through a heated die to form the desired shape. This process results in profiles with consistent cross-sections and excellent mechanical properties. In the construction of wastewater treatment tanks, FRP pultrusion profiles can be used for a variety of purposes. They can be employed as structural elements, such as beams, columns, and bracing systems, providing the necessary strength and stiffness to support the tank structure. FRP profiles can also be used as reinforcement in concrete structures, enhancing their durability and resistance to chemical attack from the wastewater. Furthermore, FRP pultrusion profiles can be designed to resist the corrosive effects of the chemicals and gases present in wastewater treatment tanks. Unlike traditional materials like steel or concrete, FRP is highly resistant to corrosion, ensuring a longer service life and reduced maintenance costs. Additionally, FRP profiles offer advantages in terms of installation and transportation. They are lightweight, allowing for easier handling and reduced labor requirements during construction. The modular nature of FRP profiles also facilitates quick assembly and disassembly, making maintenance and modifications more convenient. Overall, the use of FRP pultrusion profiles in the construction of wastewater treatment tanks provides numerous benefits, including high strength, corrosion resistance, durability, and ease of installation. These advantages make FRP a reliable and cost-effective choice for wastewater treatment facilities.

- Q: Can FRP pultrusion profiles be used in the aerospace industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the aerospace industry. These profiles offer numerous advantages such as high strength-to-weight ratio, corrosion resistance, and design flexibility. They can be used in various aerospace applications including structural components, interior parts, and electrical systems. Additionally, their non-conductive properties make them suitable for applications where electrical insulation is required.

- Q: What are the maintenance requirements for FRP pultrusion profiles?

- The maintenance requirements for FRP pultrusion profiles are generally low. They are corrosion-resistant and do not require regular painting or coating. However, it is recommended to clean them periodically with mild soap and water to remove dirt and debris. Inspections should also be conducted to check for any signs of damage or wear, and any issues should be addressed promptly to ensure the profiles' longevity and performance.

- Q: How do FRP pultrusion profiles perform in coastal environments?

- FRP pultrusion profiles perform exceptionally well in coastal environments due to their inherent resistance to corrosion, moisture, and UV radiation. Thanks to their non-metallic composition, they are not susceptible to rust or degradation caused by saltwater exposure. Additionally, FRP profiles have high strength-to-weight ratios, making them ideal for applications in coastal areas where weight and durability are crucial.

- Q: Can FRP pultrusion profiles be used in telecommunications applications?

- Telecommunications applications can utilize FRP pultrusion profiles, which offer a range of advantages that render them suitable for such infrastructure. To begin with, these profiles possess the desirable combination of being lightweight and strong, making them an excellent choice for supporting antennas, cable trays, and equipment racks. Their high strength-to-weight ratio enables easier installation and transportation while providing the necessary structural support. Moreover, FRP pultrusion profiles display corrosion resistance, a crucial characteristic for telecommunications applications. Given the exposure of telecommunications infrastructure to harsh environments like moisture, chemicals, and extreme temperatures, FRP's non-corrosive properties guarantee long-term durability and reliability, distinguishing it from traditional materials such as steel or wood. Additionally, FRP pultrusion profiles offer electrical insulation properties, which are vital in telecommunications applications. By not conducting electricity, they ensure safety in areas where electrical equipment is present. This feature prevents electrical interference and preserves the integrity of the telecommunications system. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements, as they can be manufactured in various shapes and sizes. This flexibility allows for the efficient design of telecommunications infrastructure, making FRP pultrusion profiles suitable for a wide range of applications within the industry. In conclusion, FRP pultrusion profiles prove to be well-suited for telecommunications applications due to their lightweight yet strong nature, corrosion resistance, electrical insulation properties, and customization possibilities. These attributes guarantee their reliability in supporting and protecting telecommunications infrastructure.

- Q: Are FRP pultrusion profiles resistant to fungal growth?

- Yes, FRP pultrusion profiles are highly resistant to fungal growth. The composite materials used in FRP pultrusion, such as fiberglass and resin, do not provide a suitable environment for fungi to grow. Additionally, the smooth surface of FRP profiles makes it difficult for fungi to attach and thrive. Hence, FRP pultrusion profiles are an excellent choice for applications where resistance to fungal growth is required.

- Q: How do FRP pultrusion profiles perform in high-traffic areas?

- FRP pultrusion profiles are an excellent choice for high-traffic areas due to their exceptional performance characteristics. These profiles are made of reinforced fiberglass and resin, resulting in a highly durable material that can withstand heavy loads and constant foot traffic. One of the key advantages of FRP pultrusion profiles is their high strength-to-weight ratio. This makes them lightweight yet incredibly strong, allowing them to handle heavy loads without sacrificing their structural integrity. Additionally, their non-corrosive nature makes them ideal for areas with high foot traffic, where exposure to moisture, chemicals, and other corrosive elements is common. FRP pultrusion profiles also possess excellent resistance to wear and abrasion. This means that even in high-traffic areas, where constant footfalls and movement can cause conventional materials to deteriorate quickly, FRP profiles remain unaffected, maintaining their original appearance and functionality for an extended period. Furthermore, these profiles are highly resistant to UV radiation, which means they do not degrade or fade when exposed to sunlight. This is particularly important for high-traffic areas that are outdoors or have large windows, as the profiles will maintain their strength and aesthetics even under constant exposure to the sun. In terms of maintenance, FRP pultrusion profiles require minimal upkeep. They do not require regular painting or sealing, as their color and finish are built into the material itself. This significantly reduces maintenance costs and efforts, making them a cost-effective choice for high-traffic areas. Overall, FRP pultrusion profiles are an excellent option for high-traffic areas due to their exceptional strength, durability, resistance to wear and abrasion, non-corrosive properties, UV resistance, and low maintenance requirements. Their ability to withstand heavy loads and constant foot traffic ensures their long-lasting performance, making them a reliable choice for any high-traffic environment.

- Q: Are FRP pultrusion profiles resistant to humidity or moisture?

- FRP pultrusion profiles exhibit remarkable resistance to humidity and moisture. Their inherent ability to repel water absorption stems from the amalgamation of fiberglass reinforcement and a polymer resin matrix. Unlike conventional materials such as wood or metal, FRP pultrusion profiles remain unaffected by moisture or heightened humidity levels, as they neither expand, distort, nor corrode. This moisture resistance renders FRP pultrusions suitable for a diverse array of applications spanning across industries like construction, infrastructure, and marine environments. Moreover, the resistance to moisture can be further bolstered by applying additional protective coatings or surface finishes to FRP pultrusion profiles, thereby escalating their resilience against humidity and moisture.

Send your message to us

Latest Style FRP Pultrusion Profiles with Anti-Corrosion for Pultruded Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 34 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords