All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Are FRP pultrusion profiles resistant to weathering and aging?

Yes, FRP pultrusion profiles are highly resistant to weathering and aging. The combination of strong fibers and a durable resin matrix in FRP pultrusion profiles provides excellent resistance to UV radiation, moisture, extreme temperatures, and other environmental factors. This ensures their long-term performance and stability even in harsh weather conditions.

How do FRP pultrusion profiles compare to traditional building materials like steel and wood?

FRP pultrusion profiles offer several advantages over traditional building materials like steel and wood. First, FRP profiles are incredibly lightweight, making them easier to handle and transport. Additionally, they have high strength-to-weight ratios, meaning they are stronger than steel or wood while being significantly lighter. FRP profiles are also corrosion-resistant, making them ideal for outdoor or marine applications. Moreover, they do not rot, warp, or decay like wood, ensuring long-term durability. Lastly, FRP profiles have excellent electrical and thermal insulation properties, making them suitable for a wide range of applications in various industries.

Are FRP pultrusion profiles resistant to earthquake forces?

Yes, FRP pultrusion profiles are generally resistant to earthquake forces. The high strength-to-weight ratio and inherent flexibility of FRP materials make them capable of absorbing and dissipating seismic energy, reducing the risk of structural damage during an earthquake. However, it is important to note that the overall resistance of FRP pultrusion profiles to earthquake forces also depends on the design, installation, and specific requirements of the application.

What are the strength properties of FRP pultrusion profiles?

The strength properties of FRP (Fiber Reinforced Polymer) pultrusion profiles are generally characterized by their high tensile strength, stiffness, and resistance to corrosion. They are known for their exceptional strength-to-weight ratio, making them lightweight yet capable of withstanding heavy loads. FRP pultrusion profiles also exhibit high flexural strength and have excellent resistance to fatigue, impact, and creep. Additionally, they have low thermal conductivity and are electrically non-conductive.

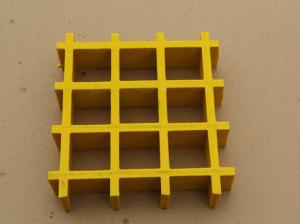

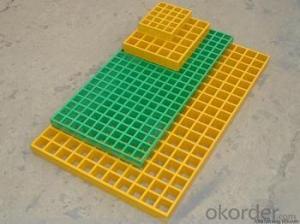

Wholesale FRP Pultrusion Profiles from supplier in Papua New Guinea

With our FRP Pultrusion Profiles, you can be assured of excellent quality and durability for your projects in Papua New Guinea. Our profiles are made using the latest pultrusion technology, ensuring high strength and resistance to corrosion, chemicals, and UV radiation. Whether you need profiles for structural applications, electrical insulation, or any other specific requirements, we have a wide range of options to meet your needs.

At our company, we understand the importance of providing comprehensive services to our customers. Our dedicated sales team will assist you throughout the procurement process, from understanding your requirements to providing competitive quotations. We also offer technical support, ensuring that you have all the information and guidance you need to make informed decisions.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to extensive resources and expertise. This allows us to offer competitive prices without compromising on quality. We have a strong track record of successful market development in Papua New Guinea, and our experience ensures that we understand the unique challenges and requirements of this region.

In summary, by choosing our FRP Pultrusion Profiles for your projects in Papua New Guinea, you can benefit from our comprehensive services, high-quality products, and valuable experience. Let us be your trusted partner in fulfilling your FRP procurement needs. Contact us today to discuss your requirements and how we can assist you.

At our company, we understand the importance of providing comprehensive services to our customers. Our dedicated sales team will assist you throughout the procurement process, from understanding your requirements to providing competitive quotations. We also offer technical support, ensuring that you have all the information and guidance you need to make informed decisions.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to extensive resources and expertise. This allows us to offer competitive prices without compromising on quality. We have a strong track record of successful market development in Papua New Guinea, and our experience ensures that we understand the unique challenges and requirements of this region.

In summary, by choosing our FRP Pultrusion Profiles for your projects in Papua New Guinea, you can benefit from our comprehensive services, high-quality products, and valuable experience. Let us be your trusted partner in fulfilling your FRP procurement needs. Contact us today to discuss your requirements and how we can assist you.