All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the different coil width tolerances for stainless steel coils?

There are various coil width tolerances for stainless steel coils, depending on the specific requirements and standards set by manufacturers and industries. These tolerances may range from +/- 0.005 inches to +/- 0.062 inches, or even more, depending on the thickness and width of the stainless steel coil. It is important to consult the manufacturer or supplier to determine the specific tolerances for a particular stainless steel coil.

How is stainless steel coil tested for chemical composition?

Stainless steel coil is typically tested for chemical composition using various methods such as optical emission spectrometry, X-ray fluorescence analysis, or wet chemical analysis. These techniques help determine the elemental composition of the stainless steel coil, ensuring it meets the required specifications and quality standards.

How is stainless steel coil used in the pharmaceutical industry?

Stainless steel coil is extensively used in the pharmaceutical industry for various applications such as manufacturing equipment, storage tanks, and piping systems. Its corrosion resistance and hygienic properties make it ideal for ensuring product quality and safety in pharmaceutical production processes. Additionally, stainless steel coil is also used for constructing sterile environments, such as cleanrooms and controlled environments, where maintaining cleanliness and preventing contamination are crucial.

What are the common methods of tempering stainless steel coils?

The common methods of tempering stainless steel coils include heat treatment processes such as annealing, quenching, and tempering. Annealing involves heating the stainless steel coils to a specific temperature and then slowly cooling them, which helps to soften the material and improve its ductility. Quenching, on the other hand, involves rapidly cooling the heated stainless steel coils to increase their hardness and strength. Finally, tempering involves reheating the quenched stainless steel coils to a lower temperature, followed by controlled cooling, to reduce internal stresses and improve toughness while maintaining an optimal balance of hardness and ductility.

What is the difference between a stainless steel coil and a sheet?

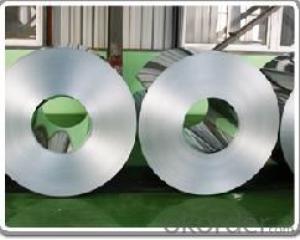

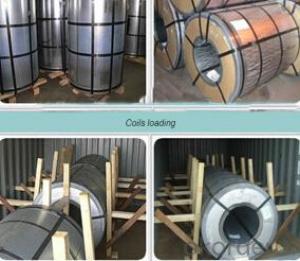

A stainless steel coil is a long, continuous piece of stainless steel that is wound into a coil shape, while a stainless steel sheet is a flat, rectangular piece of stainless steel. The coil is typically used for manufacturing purposes such as producing pipes, tubes, or other specialized shapes, while the sheet is commonly used for applications like construction, automotive, or household appliances.

Wholesale Stainless Steel Coil from supplier in Papua New Guinea

Our team of experts is well-equipped to handle all your requirements and provide you with the best solutions for your stainless steel coil needs. We have a wide range of products that cater to various industries, including construction, automotive, and manufacturing.

In addition to our comprehensive product range, we also offer competitive pricing and flexible payment options to ensure that you get the best value for your money. Our sales team is dedicated to providing you with personalized service and timely communication, ensuring a smooth and hassle-free procurement process.

Furthermore, we understand that technical support is crucial for successful project execution. Our technical team is always available to answer any questions you may have and provide guidance on product selection, installation, and maintenance.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and expertise to meet all your stainless steel coil requirements in Papua New Guinea. Our strong market presence and years of experience in the region have given us valuable insights and project expertise, enabling us to provide you with the best solutions for your specific needs.

Contact us today to discuss your stainless steel coil requirements in Papua New Guinea, and let us provide you with convenient and efficient one-stop procurement services. We look forward to partnering with you and delivering exceptional products and services.

In addition to our comprehensive product range, we also offer competitive pricing and flexible payment options to ensure that you get the best value for your money. Our sales team is dedicated to providing you with personalized service and timely communication, ensuring a smooth and hassle-free procurement process.

Furthermore, we understand that technical support is crucial for successful project execution. Our technical team is always available to answer any questions you may have and provide guidance on product selection, installation, and maintenance.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and expertise to meet all your stainless steel coil requirements in Papua New Guinea. Our strong market presence and years of experience in the region have given us valuable insights and project expertise, enabling us to provide you with the best solutions for your specific needs.

Contact us today to discuss your stainless steel coil requirements in Papua New Guinea, and let us provide you with convenient and efficient one-stop procurement services. We look forward to partnering with you and delivering exceptional products and services.