All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

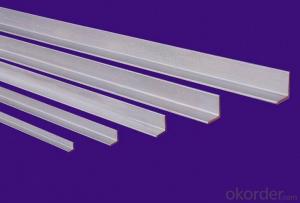

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is special steel used in the development of high-performance sports cars?

Special steel is used in the development of high-performance sports cars to enhance their strength, durability, and overall performance. It is specifically chosen for critical components such as engine parts, chassis, and suspension systems, as it offers superior strength-to-weight ratio, improved heat resistance, and excellent fatigue resistance. This allows for increased power output, better handling, and enhanced safety, making special steel an indispensable material in building high-performance sports cars.

How does boron improve the hardenability of steel, and where is it commonly used?

Boron improves the hardenability of steel by forming very fine and evenly distributed carbides during the heat treatment process. These carbides enhance the steel's ability to be hardened through quenching, resulting in improved strength and wear resistance. Boron also helps to refine the grain size of the steel, leading to improved toughness.

Boron is commonly used in the production of high-strength and wear-resistant steels, such as automotive and aerospace components, cutting tools, and construction equipment. It is also utilized in the manufacturing of springs, gears, and other critical components that require enhanced hardness and durability.

What are the advancements in steel technology for clean energy applications?

Advancements in steel technology for clean energy applications include the development of high-strength and corrosion-resistant steels, which are essential for building efficient wind turbines and solar panels. Additionally, the use of advanced steel alloys has allowed for the construction of lightweight and durable structures for offshore wind farms and wave energy converters. Steel manufacturers are also exploring new techniques to reduce carbon emissions during the production process, such as using hydrogen as a reducing agent instead of coal.

What is the process of making special steel?

The process of making special steel involves several steps such as melting iron ore and other alloying elements in a furnace, followed by refining the molten metal to remove impurities. This refined molten metal is then solidified into a desired shape through processes like casting, rolling, or forging. The steel is further heat treated to enhance its mechanical properties and undergoes various finishing processes to achieve the desired surface finish and dimensions. Overall, the process of making special steel requires careful control of composition, temperature, and mechanical treatments to create a high-quality and specialized steel product.

Wholesale Special Steel from supplier in Kenya

Our Special Steel products are sourced from reputable manufacturers and undergo strict quality control measures to ensure their durability and reliability. We offer a wide range of Special Steel products, including alloy steel, carbon steel, stainless steel, tool steel, and more.

In addition to our comprehensive product range, we also provide value-added services such as customized cutting, drilling, and machining to meet your specific requirements. Our team of skilled professionals is equipped with the expertise and knowledge to deliver precise and efficient solutions for your projects.

At our company, customer satisfaction is our top priority. We strive to build long-term relationships with our clients by providing exceptional customer service and support. Our dedicated team is available to assist you throughout the entire procurement process, from product selection to after-sales support.

As a subsidiary of CNBM, we have access to a vast network of resources and expertise, enabling us to offer competitive pricing and efficient logistics solutions. We are committed to delivering on-time deliveries and ensuring that your projects stay on schedule.

Choose us as your preferred supplier of Special Steel in Kenya and benefit from our extensive product range, reliable support, and valuable expertise. Contact us today to discuss your requirements and let us provide you with a seamless procurement experience.

In addition to our comprehensive product range, we also provide value-added services such as customized cutting, drilling, and machining to meet your specific requirements. Our team of skilled professionals is equipped with the expertise and knowledge to deliver precise and efficient solutions for your projects.

At our company, customer satisfaction is our top priority. We strive to build long-term relationships with our clients by providing exceptional customer service and support. Our dedicated team is available to assist you throughout the entire procurement process, from product selection to after-sales support.

As a subsidiary of CNBM, we have access to a vast network of resources and expertise, enabling us to offer competitive pricing and efficient logistics solutions. We are committed to delivering on-time deliveries and ensuring that your projects stay on schedule.

Choose us as your preferred supplier of Special Steel in Kenya and benefit from our extensive product range, reliable support, and valuable expertise. Contact us today to discuss your requirements and let us provide you with a seamless procurement experience.