All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do changes in coil width consistency impact the manufacturing process of electronic enclosures and components?

Changes in coil width consistency can significantly impact the manufacturing process of electronic enclosures and components. Consistent coil width is crucial for proper mechanical and electrical fit of the components within the enclosure. Inconsistent coil width can lead to misalignment, poor contact, or even damage to the components. It can also affect the overall integrity and functionality of the enclosure, potentially causing performance issues or failures. Therefore, maintaining a consistent coil width is essential for ensuring the quality and reliability of electronic enclosures and components during the manufacturing process.

What is the significance of coil cleanliness in the manufacturing of components for medical devices and instruments?

Coil cleanliness is of utmost significance in the manufacturing of components for medical devices and instruments due to several reasons. Firstly, clean coils ensure the overall hygiene and safety of the medical devices, preventing any potential contamination or infection risks to patients. Secondly, maintaining coil cleanliness enhances the performance and longevity of the components, ensuring their optimal functioning and reliability. Additionally, clean coils help to minimize the chances of equipment malfunctions or failures, reducing the need for frequent repairs or replacements. Overall, coil cleanliness plays a vital role in upholding the quality, safety, and effectiveness of medical devices and instruments, making it an essential aspect of their manufacturing process.

What measures are in place to maintain coil flatness during transportation?

There are several measures in place to maintain coil flatness during transportation. Firstly, coils are typically packed and secured using steel straps or bands to prevent any movement or shifting during transit. Additionally, specialized coil carriers or cradles are used to provide support and distribute the weight evenly, minimizing the risk of deformation. Some carriers also incorporate cushioning materials or rubber pads to absorb shocks and vibrations that could potentially impact coil flatness. Furthermore, careful handling and loading techniques are employed to avoid excessive pressure or bending forces that could compromise the flatness. Overall, these measures ensure that coils remain flat and undamaged throughout the transportation process.

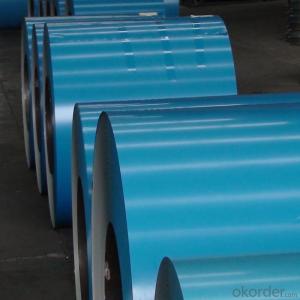

What are steel coils?

Steel coils are long, flat, and continuous sheets of steel that have been wound into a coil shape. These coils are commonly used in various industries for a wide range of purposes, including manufacturing, construction, and transportation. They are often processed and further fabricated into different products such as pipes, automotive parts, appliances, and building materials.

Wholesale Steel Coils from supplier in Papua New Guinea

With our expertise and resources, we can ensure timely delivery of high-quality Steel Coils to your desired locations in Papua New Guinea. Our sales team is dedicated to understanding your specific needs and providing tailored solutions to meet your requirements. We offer competitive pricing and flexible payment terms to accommodate your budget.

In addition to sales, we provide comprehensive quotations that include detailed information about our products, pricing, and delivery terms. Our technical support team is available to assist you with any inquiries or issues you may have regarding our Steel Coils. We have a wealth of knowledge and experience in the industry, allowing us to offer valuable insights and recommendations to optimize your projects.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and manufacturers, ensuring a seamless procurement process. Our strong relationships with trusted partners enable us to source high-quality Steel Coils that meet international standards. We understand the importance of timely delivery, and we work closely with our logistics partners to ensure smooth transportation and on-time arrival of your orders.

Whether you require Steel Coils for construction, manufacturing, or any other application, we have a wide range of products to cater to your specific needs. Our product portfolio includes various grades, sizes, and coatings to suit different project requirements. We can also provide customization options to meet unique specifications.

Overall, our years of market experience in Papua New Guinea, coupled with our comprehensive services and global network, make us your ideal partner for Steel Coils procurement. Contact us today to discuss your requirements and let us support your projects in Papua New Guinea.

In addition to sales, we provide comprehensive quotations that include detailed information about our products, pricing, and delivery terms. Our technical support team is available to assist you with any inquiries or issues you may have regarding our Steel Coils. We have a wealth of knowledge and experience in the industry, allowing us to offer valuable insights and recommendations to optimize your projects.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and manufacturers, ensuring a seamless procurement process. Our strong relationships with trusted partners enable us to source high-quality Steel Coils that meet international standards. We understand the importance of timely delivery, and we work closely with our logistics partners to ensure smooth transportation and on-time arrival of your orders.

Whether you require Steel Coils for construction, manufacturing, or any other application, we have a wide range of products to cater to your specific needs. Our product portfolio includes various grades, sizes, and coatings to suit different project requirements. We can also provide customization options to meet unique specifications.

Overall, our years of market experience in Papua New Guinea, coupled with our comprehensive services and global network, make us your ideal partner for Steel Coils procurement. Contact us today to discuss your requirements and let us support your projects in Papua New Guinea.