Latest FRP Pultrusion Profiles for Anti-Corrosion and Anti-Rust Pultruded Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

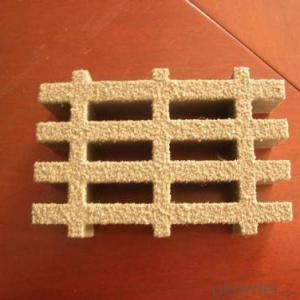

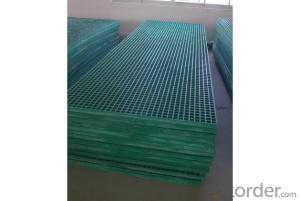

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

SPECIFICATION

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin, VE resin, Phenol resin

Color choice: Yellow, gray, green, custom color

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper,

construction engineering,

spinning, marine engineering.

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk,

foot bridge,

equipment safety fence,

scaffold.

COMPANT DESCRIPTION

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce FRP machines and FRP products.

2.Q:If can customized by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarantee?

A:Gurantee is one year.

5.Q:If you can training?

A:yes ,we can training in our factory also can send engineers to your factory training.

PICTURES

- Q: Can FRP pultrusion profiles be used in water treatment plants?

- Yes, FRP pultrusion profiles can be used in water treatment plants. FRP (Fiber-Reinforced Polymer) is a corrosion-resistant material that is well-suited for water treatment applications. It is lightweight, durable, and has excellent chemical resistance properties, making it ideal for use in environments with exposure to water and various chemicals. Additionally, FRP pultrusion profiles offer design flexibility and can be customized to meet specific project requirements.

- Q: How do FRP pultrusion profiles compare to fiberglass reinforced panels (FRP)?

- FRP pultrusion profiles and fiberglass reinforced panels (FRP) are both commonly used materials in various industries due to their high strength and durability. However, there are some notable differences when comparing these two FRP products. 1. Manufacturing Process: FRP pultrusion profiles are created through a continuous pultrusion process, where fibers are pulled through a resin bath and then cured using heat or ultraviolet light. This results in a solid and uniform profile with consistent mechanical properties. On the other hand, fiberglass reinforced panels are made by combining layers of fiberglass mat and resin, which are typically molded or pressed together. This process can sometimes result in variations in thickness and mechanical properties across the panel. 2. Structural Strength: FRP pultrusion profiles are known for their exceptional strength-to-weight ratio. The continuous fiber reinforcement used in pultrusion provides high stiffness and load-bearing capacity, making them suitable for structural applications. Conversely, while fiberglass reinforced panels are also strong, they may not possess the same level of structural integrity as pultrusion profiles due to the potential for variations in resin content and fiber distribution. 3. Design Flexibility: FRP pultrusion profiles offer greater design flexibility compared to fiberglass reinforced panels. The pultrusion process allows for the incorporation of various shapes and configurations, such as I-beams, angles, tubes, and custom profiles. This versatility enables engineers to tailor the profiles to specific project requirements. In contrast, fiberglass reinforced panels are typically limited to flat or slightly curved surfaces and do not provide the same level of customization. 4. Surface Finish: FRP pultrusion profiles often have a smooth and consistent surface finish due to the pultrusion process. This makes them more aesthetically appealing and suitable for applications where appearance is important. Fiberglass reinforced panels, on the other hand, may have a textured or uneven surface, which can impact their visual appeal in certain applications. 5. Cost: When comparing costs, FRP pultrusion profiles are generally more expensive than fiberglass reinforced panels. The pultrusion process requires specialized equipment and has higher manufacturing costs. Fiberglass reinforced panels, on the other hand, have lower production costs due to their simpler manufacturing process. However, it is important to consider the specific application requirements and long-term performance when evaluating the cost-effectiveness of these materials. In summary, FRP pultrusion profiles and fiberglass reinforced panels have their own unique characteristics and advantages. The choice between the two will depend on factors such as structural requirements, design flexibility, surface finish, and cost considerations.

- Q: Can FRP pultrusion profiles be used in the water treatment industry?

- Indeed, the water treatment industry can make use of FRP pultrusion profiles. These profiles, made of Fiber Reinforced Polymer, are widely recognized for their exceptional resistance to corrosion, impressive strength, and long-lasting durability. These qualities render them highly appropriate for a diverse range of applications within the water treatment field. In particular, FRP pultrusion profiles can be employed in the construction of water treatment tanks, pipes, and other crucial infrastructure. They exhibit remarkable resistance to chemicals, including those commonly employed in water treatment procedures. This resistance to corrosion ensures that equipment enjoys an extended lifespan and maintenance costs are minimized. Moreover, FRP pultrusion profiles boast an impressive strength-to-weight ratio, making them an ideal choice for applications that necessitate lightweight yet robust materials. This quality facilitates the easier installation and transportation of water treatment equipment. Furthermore, the flexibility in design offered by FRP pultrusion profiles is worth noting. Such profiles can be manufactured in a wide array of shapes and sizes to cater to specific project requirements. This capability allows for the customization and optimization of water treatment systems, guaranteeing the efficiency and effectiveness of water treatment processes. In summary, FRP pultrusion profiles present themselves as a dependable and cost-effective option for the water treatment industry. Their excellent resistance to corrosion, exceptional strength, and design flexibility make them highly suitable for numerous applications within water treatment systems.

- Q: Can FRP pultrusion profiles be used in the construction of recreational vehicles (RVs)?

- Indeed, FRP pultrusion profiles find utility in the construction of recreational vehicles (RVs). Renowned for their remarkable strength-to-weight ratio, resistance to corrosion, and durability, FRP pultrusion profiles prove to be an exemplary material for diverse applications, including RV construction. The fabrication of RVs necessitates materials that are both lightweight and robust to ensure fuel efficiency and structural integrity. FRP pultrusion profiles satisfy these requirements as they possess both lightness and high tensile strength, enabling the creation of sturdy and enduring RVs that are also lightweight and easily towed. Furthermore, FRP pultrusion profiles exhibit exceptional resistance to environmental elements such as moisture, UV radiation, and chemicals. Consequently, they prove to be suitable for outdoor applications, including RVs, where exposure to various weather conditions is inevitable. Additionally, FRP pultrusion profiles offer the advantage of effortless customization and adaptability to diverse shapes and sizes, thus meeting the design flexibility essential in RV construction. Beyond serving as structural components like frames, chassis, and supports, they can be employed for interior and exterior panels, floors, and roofs. All in all, the utilization of FRP pultrusion profiles in the construction of recreational vehicles bestows numerous benefits, including strength, durability, lightness, and resistance to environmental factors. These characteristics establish FRP pultrusion profiles as a dependable choice for RV manufacturers aspiring to fabricate high-quality, efficient, and long-lasting vehicles.

- Q: Can FRP pultrusion profiles be used in protective barriers?

- FRP pultrusion profiles have the capability to be utilized in protective barriers. These profiles possess notable attributes such as a high strength-to-weight ratio, resistance to corrosion, and exceptional durability, which make them suitable for a wide array of applications, including protective barriers. They can be custom-designed and manufactured to meet specific requirements, such as impact resistance, load-bearing capacity, and fire resistance. Furthermore, FRP pultrusion profiles are highly malleable, allowing for easy molding into various shapes and sizes, thus providing flexibility in barrier design. Whether the purpose is to create noise barriers, security fences, or safety barriers, FRP pultrusion profiles offer a reliable and cost-effective solution for protective barriers across multiple industries.

- Q: Are FRP pultrusion profiles resistant to wear or abrasion?

- Yes, FRP pultrusion profiles are highly resistant to wear and abrasion. The combination of strong reinforcing fibers and a durable resin matrix makes them capable of withstanding harsh conditions and maintaining their structural integrity over time, even in high-stress environments. This resistance to wear and abrasion makes FRP pultrusion profiles an excellent choice for applications that require long-lasting and low-maintenance solutions.

- Q: Can FRP pultrusion profiles be used in the construction of highway guardrails?

- Yes, FRP pultrusion profiles can be used in the construction of highway guardrails. FRP (Fiber Reinforced Polymer) pultrusion profiles offer excellent strength-to-weight ratio, corrosion resistance, and durability, making them a suitable choice for guardrails. They are lightweight, easy to install, and require minimal maintenance, making them cost-effective in the long run. Additionally, FRP profiles can be molded into various shapes and sizes to meet specific design requirements, ensuring the safety and effectiveness of the highway guardrails.

- Q: How do FRP pultrusion profiles perform in seismic zones?

- Due to their inherent properties and characteristics, FRP pultrusion profiles are highly suitable for use in seismic zones. One of the main advantages of these profiles is their excellent strength-to-weight ratio, which allows them to effectively withstand seismic forces without adding significant weight to the structure. In seismic zones, structures and buildings experience intense ground motions during an earthquake. FRP pultrusion profiles possess high stiffness and strength, enabling them to effectively resist the lateral forces caused by seismic activity. These profiles have a high modulus of elasticity, allowing them to maintain their shape and structural integrity even under extreme seismic loads. Furthermore, FRP pultrusions exhibit outstanding corrosion resistance, making them highly durable in seismic zones. Unlike traditional materials like steel or concrete, FRP profiles do not corrode when exposed to moisture, chemicals, or salts commonly found in seismic regions. This corrosion resistance ensures the long-term performance and structural integrity of FRP pultrusion profiles, even in harsh environmental conditions. Another advantage of FRP pultrusions in seismic zones is their flexibility and ability to dampen vibrations. During an earthquake, ground motions cause structures to vibrate. The inherent damping properties of FRP materials help absorb and dissipate these vibrations, reducing the potential for structural damage. Additionally, FRP pultrusion profiles can be designed and manufactured to meet specific seismic requirements and codes. They can be reinforced with additional layers or designed with specific geometries to enhance their seismic performance, ensuring compliance with necessary safety standards in seismic zones. Overall, FRP pultrusion profiles offer numerous benefits for use in seismic zones. Their high strength-to-weight ratio, corrosion resistance, damping properties, and design flexibility make them an excellent choice for constructing seismic-resistant structures while ensuring durability and safety.

- Q: Can FRP pultrusion profiles be used in chemical processing plants?

- FRP pultrusion profiles are indeed applicable for use in chemical processing plants. These profiles possess exceptional resistance to corrosion, rendering them suitable for chemical settings that frequently involve exposure to diverse chemicals, acids, and bases. Moreover, FRP pultrusion profiles exhibit a combination of lightness and strength, allowing for customization to satisfy specific design prerequisites, thereby enabling their adaptability for various applications within a chemical processing plant. Additionally, they possess non-conductive electrical properties, proving advantageous in environments necessitating electrical insulation. On the whole, FRP pultrusion profiles present a durable and cost-efficient resolution for chemical processing plants, as they deliver long-term performance and reduce maintenance expenses.

- Q: Are FRP pultrusion profiles resistant to UV degradation?

- Yes, FRP pultrusion profiles are generally resistant to UV degradation. Pultrusion profiles made from fiberglass reinforced plastic (FRP) are manufactured using a combination of resin and glass fibers. The resin used in the manufacturing process is typically formulated to provide resistance to UV radiation. This UV resistance helps to protect the FRP pultrusion profiles from the harmful effects of prolonged exposure to sunlight. FRP pultrusion profiles have been extensively tested and have demonstrated excellent resistance to UV degradation. They are commonly used in outdoor applications where they are exposed to sunlight, such as in construction, infrastructure, and marine industries. UV resistance ensures that the FRP pultrusion profiles maintain their structural integrity, color, and aesthetic appearance over an extended period of time. However, it is important to note that the level of UV resistance may vary depending on the specific formulation of the resin used in the manufacturing process. Different manufacturers may use different resins with varying levels of UV stabilizers. It is recommended to consult with the manufacturer or supplier to ensure that the specific FRP pultrusion profiles being used are designed to withstand the UV conditions of the intended application. Regular maintenance and periodic inspection of the FRP pultrusion profiles are also important to ensure their long-term UV resistance. This may include cleaning, applying protective coatings, or using UV-blocking additives if necessary. By taking these precautions, the UV resistance of FRP pultrusion profiles can be further enhanced, ensuring their durability and longevity in outdoor environments.

Send your message to us

Latest FRP Pultrusion Profiles for Anti-Corrosion and Anti-Rust Pultruded Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords