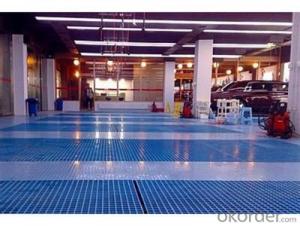

FRP Grating for Carwash Floor High Strength

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of FRP Grating for Carwash Floor:

- FRP grating for carwash square hole specifications: (38 * 38mm) 50 * 50mm

- FRP grating for carwash thickness basically divided into: (25mm 30mm 38mm) 50mm

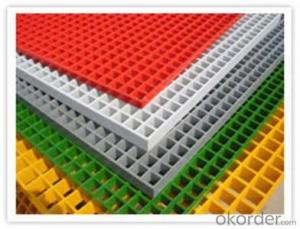

- FRP grating for carwashe commonly used colors: yellow / green / gray / black

- FRP grating entire board size: 1.22 * 3.66m = 4.4652 (meters)

- Carwash station Size:

Standard Parking: 3 * 6.1 m

Small Spaces: 2.44 * 4.88 m (recommended)

The parking: 3.66 * 4.88 m

Large spaces: 3.66 * 6.1 m

- FRP grating thickness:

25mm thickness: Suitable for general drains, the inner diameter of the support groove width not exceeding 20cm, can load about 2 tons of pressure off the car.

38mm thick: for gutters and carwash station, but the following support center spacing (horizontal and vertical) to no more than 50cm better, the car can carry three tons or less.

Detailed consultation: contact us.

- Q:Can FRP pultrusion profiles be used in the construction of water slides?

- Yes, FRP pultrusion profiles can be used in the construction of water slides. FRP stands for Fiber Reinforced Polymer, which is a composite material that offers several advantages for water slide construction. Firstly, FRP pultrusion profiles are lightweight yet incredibly strong, making them ideal for creating the structural components of water slides. These profiles have high strength-to-weight ratios, meaning they can withstand the dynamic loads and forces experienced in water slide applications without adding excessive weight to the structure. Secondly, FRP pultrusion profiles are highly resistant to corrosion, which is essential for water slide construction. Water slides are constantly exposed to water, chemicals, and harsh weather conditions, which can cause traditional materials like steel to corrode and degrade over time. FRP profiles, on the other hand, are inherently corrosion-resistant, ensuring the longevity and durability of the water slide. Additionally, FRP pultrusion profiles offer design flexibility. They can be customized to various shapes and sizes, allowing for the creation of unique and exciting water slide designs. These profiles can also be easily molded, allowing for the incorporation of various features such as slides, curves, and drops to enhance the overall water slide experience. Lastly, FRP pultrusion profiles have excellent thermal insulation properties. This is beneficial for water slides as it helps maintain the temperature of the water, preventing excessive heat loss or gain. This feature enhances the comfort and enjoyment of users while reducing energy consumption for heating or cooling the water. In conclusion, FRP pultrusion profiles are well-suited for water slide construction due to their lightweight, high strength, corrosion resistance, design flexibility, and thermal insulation properties.

- Q:Are FRP pultrusion profiles resistant to chemical spills or leaks?

- FRP pultrusion profiles are known for their high resistance to chemical spills or leaks, making them an excellent choice for construction projects. One of the main benefits of using FRP as a building material is its exceptional chemical resistance. These profiles are made by impregnating continuous fibers with a thermosetting resin, resulting in a durable composite material. The selection of the resin used in FRP pultrusion profiles depends on the specific chemical environment they will be exposed to. This allows for customization and optimization of the composite's ability to withstand different chemicals. Additionally, the fibers used in FRP are typically chemically inert, further enhancing the profiles' resistance to chemical spills or leaks. FRP pultrusion profiles have proven to be highly resistant to a wide range of chemicals, including acids, alkalis, solvents, and corrosive substances. They are commonly used in industries such as chemical processing, water and wastewater treatment, oil and gas, and marine applications, where exposure to aggressive chemicals is common. Apart from their chemical resistance, FRP pultrusion profiles offer several other advantages. They are lightweight yet strong and stiff, making them ideal for applications that require structural integrity. They are also non-conductive, non-magnetic, and have excellent electrical insulation properties. Overall, FRP pultrusion profiles are a reliable option for environments where chemical spills or leaks are a concern. They provide robust resistance to a wide variety of chemicals, ensuring long-lasting performance and minimal maintenance requirements.

- Q:Can FRP pultrusion profiles be used in the telecommunications and data communication industry?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can be used in the telecommunications and data communication industry. FRP pultruded profiles have several advantages that make them suitable for use in this industry. Firstly, FRP pultrusion profiles offer excellent electrical insulation properties, making them ideal for applications in the telecommunications and data communication industry where electrical conductivity needs to be minimized. FRP profiles do not conduct electricity, ensuring that there are no interference or grounding issues that could disrupt the transmission of data. Secondly, FRP pultrusion profiles are lightweight yet strong, providing a high strength-to-weight ratio. This makes them suitable for use in the construction of communication towers, antenna supports, and satellite dish mountings, where the profiles need to withstand wind loads and other environmental stresses. Additionally, FRP profiles have excellent corrosion resistance, which is crucial in the telecommunications and data communication industry where equipment is often exposed to harsh outdoor environments. Unlike traditional materials such as steel or aluminum, FRP profiles do not rust or corrode, ensuring the longevity and reliability of the infrastructure. Furthermore, FRP profiles can be easily customized and manufactured in various shapes and sizes to meet the specific requirements of telecommunications and data communication applications. This flexibility allows for the design and construction of complex structures that can accommodate different equipment and technologies. Overall, FRP pultrusion profiles offer a range of benefits that make them well-suited for use in the telecommunications and data communication industry. Their electrical insulation properties, lightweight yet strong nature, corrosion resistance, and flexibility in design make them a reliable choice for supporting infrastructure in this sector.

- Q:Are FRP pultrusion profiles resistant to chemicals used in mining operations?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to chemicals commonly used in mining operations. The composite material used in FRP pultrusion profiles is inherently corrosion-resistant and can withstand the harsh chemical environment typically encountered in mining. Additionally, FRP pultrusion profiles offer excellent resistance to acids, alkalis, solvents, and other chemicals, making them a durable and reliable choice for mining applications.

- Q:Are FRP pultrusion profiles resistant to sulfuric acid?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to sulfuric acid. The corrosion resistance of FRP profiles is one of their key advantages compared to traditional materials like steel or concrete. Sulfuric acid is a highly corrosive substance, but FRP pultrusion profiles can withstand its effects due to the inherent properties of the composite materials used in their construction. The corrosion resistance of FRP profiles is mainly attributed to the resin matrix that encapsulates the reinforcing fibers. Most commonly used resins in pultrusion, such as polyester, vinyl ester, or epoxy, have excellent chemical resistance properties, including resistance to sulfuric acid. However, it is important to note that the resistance of FRP pultrusion profiles to sulfuric acid can vary depending on several factors. The concentration and temperature of the acid, as well as the specific resin formulation used in the profile, can influence the overall resistance. In highly concentrated or elevated temperature environments, it is advisable to consult with the manufacturer or supplier to ensure the specific FRP profile meets the required resistance level. In general, FRP pultrusion profiles offer a high level of resistance to sulfuric acid, making them suitable for various applications in industries where this corrosive substance may be present, such as chemical processing, wastewater treatment, or mining.

- Q:Are FRP pultrusion profiles resistant to automotive fluids?

- Yes, FRP pultrusion profiles are generally resistant to automotive fluids. The inherent chemical resistance and durability of the fiberglass-reinforced plastic make it suitable for withstanding exposure to various automotive fluids such as oils, fuels, and coolants. However, it is essential to consider the specific type of fluid and consult the manufacturer's guidelines to ensure the optimal performance and longevity of the FRP profiles in automotive applications.

- Q:Are FRP pultrusion profiles non-conductive?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are non-conductive. This is because they are made up of a combination of reinforced fibers, typically fiberglass, and a polymer resin matrix. The fiberglass fibers provide the strength and stiffness, while the polymer resin acts as a binder to hold the fibers together. One of the key advantages of FRP pultrusion profiles is their excellent electrical insulation properties. Unlike metals, which are conductive, FRP profiles do not conduct electricity. This makes them ideal for applications where electrical insulation is required. In addition to being non-conductive, FRP pultrusion profiles also offer other benefits such as corrosion resistance, high strength-to-weight ratio, and low maintenance requirements. These properties make them suitable for a wide range of applications, including electrical and telecom infrastructure, chemical processing plants, bridges, and building construction. It is important to note that the non-conductive nature of FRP pultrusion profiles does not mean they cannot be made conductive if required. Special additives or coatings can be incorporated during the manufacturing process to impart conductive properties if needed.

- Q:Are FRP pultrusion profiles resistant to fire?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to fire. The composition of FRP includes a resin matrix and reinforcing fibers, such as fiberglass or carbon fiber, which provide excellent fire resistance properties. The resin matrix used in FRP typically has a high flame resistance rating, and the reinforcing fibers do not burn easily. As a result, FRP pultrusion profiles have a high ignition temperature and are inherently self-extinguishing, meaning they will not continue to burn once the flame source is removed. Additionally, FRP pultrusion profiles do not release toxic fumes or smoke when exposed to fire, making them a safer alternative to traditional materials like wood or steel. However, it is important to note that the fire resistance of FRP pultrusion profiles can vary depending on the specific resin formulation and reinforcement material used.

- Q:What are the main uses of pultruded glass fiber reinforced plastic extrusions?

- Spend entertainment mall, this is a potential market, the development of use: fishing rod, curtain rod, umbrella frame, flagpole, stuff handle, lamp, railings, handrails and staircases, radio antenna, marinas, garden tools and accessories.

- Q:Can FRP pultrusion profiles be used in the water and wastewater treatment industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the water and wastewater treatment industry. FRP pultrusion profiles are highly durable, corrosion-resistant, and have excellent mechanical properties, making them suitable for various applications in the water and wastewater treatment industry. One of the main advantages of FRP pultrusion profiles is their resistance to corrosion. Water and wastewater treatment facilities often deal with aggressive chemicals, high humidity, and corrosive environments. Traditional materials like steel or wood may deteriorate and require frequent maintenance or replacement. However, FRP pultrusion profiles are specifically designed to withstand harsh conditions without corrosion, ensuring long-term performance and reducing maintenance costs. Additionally, FRP pultrusion profiles offer excellent strength-to-weight ratio, making them ideal for structural applications in water and wastewater treatment facilities. They can be used as walkways, handrails, grating, ladders, and other structural components. The lightweight nature of FRP profiles allows for easy installation and minimizes the load on the supporting structures. Furthermore, FRP pultrusion profiles are non-conductive, providing an added safety benefit in water and wastewater treatment facilities. This property is particularly important when dealing with electrical equipment or applications near water sources, reducing the risk of electrical hazards. Moreover, FRP pultrusion profiles can be customized to meet specific design requirements, including different shapes, sizes, and colors. This flexibility allows for greater design freedom, ensuring that the profiles can be tailored to fit the specific needs of water and wastewater treatment projects. Overall, the use of FRP pultrusion profiles in the water and wastewater treatment industry offers numerous advantages, including corrosion resistance, high strength, lightweight, non-conductivity, and design flexibility. These qualities make FRP profiles a reliable and cost-effective choice for various applications in this industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Grating for Carwash Floor High Strength

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords