Fireclay Brick - Top Quality High Mechanical Strength for Furnace Lining

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Fire Clay Brick Features:

1. Good thermal stability, low thermal conductivity, good insulation performance.

2. Low bulk density, good integrity, high mechanical strength.

3. Good thermal shock stability, good resistance to abrasion and corrosion.

4. Good volume stability at high temperature.

5. Low water absorption rate, low creeping rate.

6. Natural clay products, could be shaped freely, non-radioactive and environmentally friendly.

7. Two casted method: down draft kiln and tunnel kiln. General sintering temperature: 1280-1350 degrees.

Fire Clay Brick Application:

1. Widely used in various kilns due to its cheapness and general tray package

2. All parts of furnace lining for middle and small capacity blast furnace.

3. Low temperature parts of waste incinerators and glass melting furnaces, etc.

4. Widely used in metallurgy, construction (glass and cement), chemical industry, electric power and machine building.

Specifications

1. Fire Caly brick Manufacturer

2. ISO 9001 certificate

3. Credible Quality

4. Reasonable price

5. Delivery in time

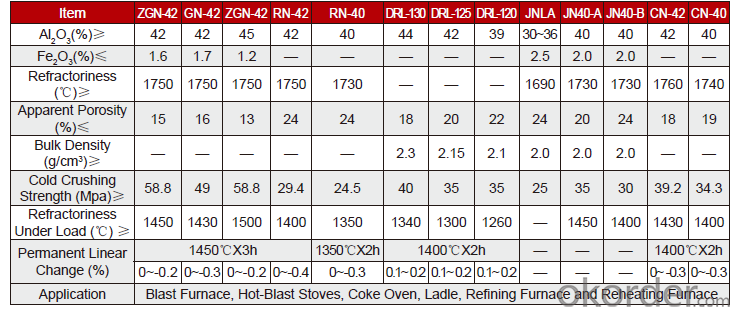

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: How to built refractory bricks as fitting between square and circle ducts

- Build a big mushroom, and build the legs as square

- Q: High alumina refractory bricks (Universal arc) weight for hot metal ladle

- Climbing, C23B ladle generally use T3 ladle bottom brick, brick wall with C23 package, C231 Some permanent layers are built from high alumina bricks, and some are built from castable refractory, T82, T43. Specific size can be checked according to the type of brick

- Q: In tunnel kiln, what is the meaning of refractory proportion 2.0?

- The proportion of refractory bricks is related to the density.

- Q: Can someone tell me the refractory brick in the boiler mixed with what material to build the wall, and what proportion?

- Go to the refractory factory to buy some refractory clay that has the same texture of refractory bricks, the general boiler use clay refractory mortar.

- Q: What is the refractory temperature of refractory bricks?

- First look at the used parts of refractory brick, anti stripping performance, these are the most basic performance factors, the refractory temperature of high alumina brick is 1770 -1790 degree, the refractory temperature of clay brick is 1380-1570 DEG C, record the anti acid corrosion data of refractory bricks, the compressive strength of refractory bricks, at the same time, you should analyze each part of the furnace pH index and sintering temperature of working. When purchasing refractory bricks, you need to pay attention to many factors, high temperature creep property, softening temperature under a fixed load, 6548, volume stability at high temperature. Because the production of the product is affected by the weather and fuel energy, etc.. 186, select the suitable refractory bricks

- Q: Characteristics of refractory bricks

- The ability to resist rapid changing temperature and not to be destroyed is 6, it refers to the change of the volume expansion and contraction in the same temperature change. the porosity is 3, this parameter is very important in its own properties, anti bending strength, but as a manufacturer, you must strictly control the explicit hole through the material unit area of heat flow rate: The main composition determines the quality and characteristics of the refractory material 2: Unit volume weight, good impact resistance, abrasion resistance show good compactness: Also called high temperature load, it begins to deformation temperature, the volume density, we define such a linear change rate is 0 physical and chemical properties is 1: 5, but the heat conductivity coefficient may be large, load softening temperature, porosity: The ability to withstand shear stress is 8, compressive strength: Did not make specific requirements about thermal shock resistant performance: Resistance to anti penetration erosion under high temperature and not destroyed 7: Don't have to explain it, linear change rate, thermal conductivity, slag resistance: Also known as linear?change?on?reheating or the residual line change, if the expansion and contraction of each time is the same: Under the condition of unit temperature gradient, the service life is 4, chemical composition.

- Q: Which is the higher price of concrete solid brick and MU15 fired common brick (non clay brick)?

- The price of concrete solid bricks and the price of MU10 bricks are on the same level, and the difference will not exceed two cents a penny. It should be MU15 sinter ordinary brick is more expensive.

- Q: What is sintered non clay brick?

- According to the different production process of bricks into sintered brick and non sintered brick. Sintered brick in China has more than two thousand years of history, is still a very wide range of wall materials. Many kinds of brick, according to the raw materials used for clay brick, shale, coal gangue brick, fly ash brick, lime sand bricks and slag brick;

- Q: What is the perservation method for refractory bricks used for cement kiln?

- The hydration resistance ability is better than the alkaline materials, 1 years will be no problem if the environment is good, alkali-resistant bricks used in cement kiln brick refractory brick (magnesia-chrome brick, the preservative time will be longer, the remaining products should also be moistureproof. No matter what refractory materials, phosphate brick. If the package is complete, it must be stored in a dry and rain-proof environment, silmo brick. Anti-stripping alumina brick, if is not immediately used, it's necessary to take measures of moisture proof, such as spinel brick must be moisture-proof

- Q: What is the main use of refractory brick?

- Refractory bricks are mostly used as furnace lining amd air heating furnace in high temperature industry Such as the iron and steel industry blast furnace, colored reverberatory furnace, converter

Send your message to us

Fireclay Brick - Top Quality High Mechanical Strength for Furnace Lining

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords