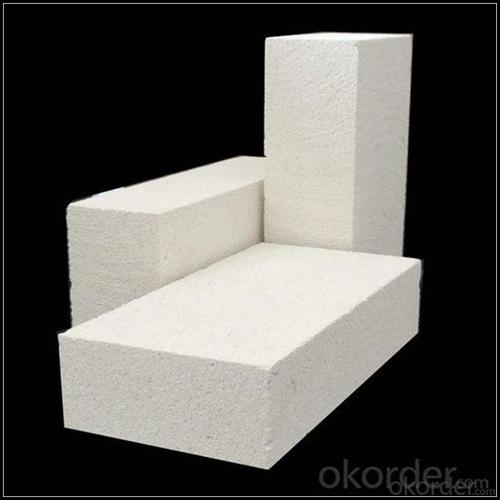

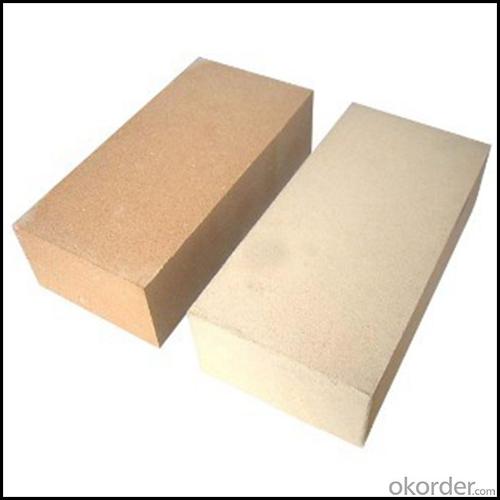

Insulating Fire Clay Refractory Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.05

- Supply Capability:

- 1800 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Acid Resistant Brick

CMAX firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

High alumina refractory brick is dense shaped refractory material. With high refractoriness and mechanical behavior under high temperature, refractory brick is the necessary material of high-temperature services, mainly used for industrial furnaces and kilns and thermal equipment.

High alumina refractory brick has wide applications, mainly used in metallurgy, construction(cement and glass), petroleum, chemical industry, electric power and machine building.

Features

1.High plasticity

2.Good thermal shock performance

3.Hardening quickly

4.Low price

Application

The product is a specialty produced from the sedimentary clay in Guangxi, with fine particle size, viscosity, high plasticity, combined with strength, good dispersing and high refractoriness advantages.

The mineral composition is mainly disordered Kaolinite >65% of, quartz <30%, Montmorillonite <10%,Illite<3%,and a small amount of Titanium minerals such as Iron.

The mineral’s particles are fine, the Kaolin particle size is less than 2μm.The clay has high plasticity, plasticity index typically greater than 25,some up to 45 above.

Data Sheet

Classification Temperature (℉/℃) | 3000/1650 |

Bulk Density (g/cm3 ) | ≤1.0 |

Thermal Conductivity | |

800℃, W/m.K | ≤0.39 |

1000℃, W/m.K | ≤0.43 |

1200℃, W/m.K | ≤0.48 |

Reheating Linear Change (%) | 1550℃×12h |

≤0.9 | |

Chemical Composition (%) | |

Al2O3 | ≥75 |

Fe2O3 | ≤0.5 |

Packaging & Shipping

Packaging Details:Be packed in fumigated wooden pallets

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research, development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection, supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Sales Network

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc. If any question, please contact us freely.

- Q: Are insulating fire bricks resistant to thermal stress?

- Yes, insulating fire bricks are resistant to thermal stress. These bricks are specially manufactured to withstand high temperatures and thermal fluctuations without cracking or breaking. They are made from refractory materials that have excellent thermal insulation properties and can handle extreme heat conditions. Insulating fire bricks have low thermal conductivity, meaning they can effectively resist heat transfer and maintain their structural integrity even when exposed to rapid temperature changes. They are commonly used in applications such as kilns, furnaces, and fireplaces, where thermal stress is a significant concern. Overall, insulating fire bricks are designed to provide reliable and durable insulation while withstanding the thermal stress associated with high-temperature environments.

- Q: Can insulating fire bricks be used in the construction of lime recovery kilns?

- Insulating fire bricks are indeed applicable for the construction of lime recovery kilns. These kilns, utilized in industrial settings, operate at high temperatures to convert limestone into lime via calcination. Specifically designed to endure elevated temperatures and offer exceptional thermal insulation, insulating fire bricks are composed of lightweight refractory materials, such as clay or silica, and possess low thermal conductivity. Within lime recovery kilns, which can reach temperatures ranging from 900 to 1200 degrees Celsius, insulating fire bricks are suitable for lining the kiln's walls, floors, and roofs. Their superior insulating properties effectively diminish heat loss, thereby enhancing energy efficiency by retaining heat within the kiln. Consequently, this results in reduced fuel consumption and cost savings. Furthermore, insulating fire bricks exhibit excellent resistance to thermal shock, a crucial characteristic in the lime recovery process. These kilns undergo repeated cycles of heating and cooling, necessitating bricks capable of withstanding temperature fluctuations without cracking or disintegrating. Ultimately, insulating fire bricks prove to be a fitting choice for lime recovery kilns due to their capacity to withstand high temperatures, provide thermal insulation, and resist thermal shock.

- Q: Are insulating fire bricks resistant to corrosion?

- In general, insulating fire bricks exhibit resistance to corrosion. They are composed of high-temperature materials like alumina, silica, and other refractory substances, which grant them exceptional protection against chemical corrosion. These bricks have been specifically engineered to endure elevated temperatures and harsh surroundings, rendering them highly impervious to corrosion caused by acids, alkalis, and other corrosive agents. Nonetheless, it is crucial to acknowledge that the degree of corrosion resistance can vary depending on the precise composition and manufacturing process of the insulating fire brick. Thus, it is recommended to consult the manufacturer or supplier for detailed information regarding the corrosion resistance of a specific insulating fire brick.

- Q: Can insulating fire bricks be used in combination with other insulation materials?

- Insulating fire bricks can be utilized alongside other insulation materials to maximize their thermal insulation capabilities. Renowned for their exceptional thermal insulation properties, insulating fire bricks are commonly employed in kilns, furnaces, and fireplaces to effectively minimize heat transfer. However, attaining optimal thermal efficiency may necessitate additional insulation in certain instances. By merging insulating fire bricks with alternative insulation materials, the overall insulation performance can be significantly augmented. For instance, ceramic fiber blankets or boards can be employed in conjunction with insulating fire bricks to furnish supplementary insulation and bridge any gaps or joints between the bricks. This amalgamation aids in minimizing heat loss and elevating energy efficiency. Moreover, utilizing multiple insulation materials can confer additional advantages, such as heightened fire resistance, enhanced sound insulation, and fortified structural integrity. By skillfully combining diverse insulation materials, a more efficacious insulation system can be fashioned to meet the specific requirements of various applications. When combining different insulation materials, it is imperative to consider their compatibility and adherence to one another. Each material may possess distinct thermal properties, density, and installation prerequisites, necessitating strict adherence to the manufacturer's recommendations and guidelines for appropriate installation. In conclusion, the utilization of insulating fire bricks in conjunction with other insulation materials is instrumental in augmenting thermal insulation and overall performance across diverse applications. However, ensuring compatibility and adhering to proper installation guidelines is vital in order to achieve optimal outcomes.

- Q: Can insulating fire bricks be used in the construction of steel production furnaces?

- Certainly, insulating fire bricks have the capability to be employed in the construction of steel production furnaces. These bricks have been specifically engineered to endure extreme temperatures and offer exceptional thermal insulation, rendering them suitable for a wide range of industrial applications, including steel production. They are manufactured using lightweight materials with low thermal conductivity, enabling them to effectively minimize heat loss and enhance energy efficiency within furnaces. Furthermore, these bricks exhibit remarkable resistance to thermal shock, a crucial property for steel production processes involving rapid heating and cooling. In summary, utilizing insulating fire bricks in the construction of steel production furnaces can optimize performance, reduce energy consumption, and enhance the overall efficiency of the steelmaking process.

- Q: Are insulating fire bricks resistant to chlorine gas?

- Yes, insulating fire bricks are generally resistant to chlorine gas. Insulating fire bricks are made from refractory materials, which are designed to withstand high temperatures and resist chemical corrosion. Chlorine gas is a highly reactive substance and can cause corrosion or damage to many materials. However, insulating fire bricks have a high resistance to chemical attack, making them suitable for applications where they may come into contact with chlorine gas. It is important to note that the specific composition and quality of the insulating fire bricks can vary, so it is always recommended to consult the manufacturer or supplier for specific information regarding their resistance to chlorine gas.

- Q: Can insulating fire bricks be used for insulation in cryogenic applications?

- Yes, insulating fire bricks can be used for insulation in cryogenic applications. These bricks have excellent thermal properties that make them suitable for maintaining low temperatures and preventing the transfer of heat in cryogenic environments. They are designed to resist extreme cold and can effectively insulate against the loss of thermal energy, making them a reliable choice for cryogenic insulation.

- Q: Can insulating fire bricks be used in heat exchangers?

- Insulating fire bricks are indeed applicable for heat exchangers. Their design aims to provide exceptional thermal insulation, making them perfect for high-temperature scenarios like heat exchangers. These bricks are crafted from lightweight substances and possess minimal thermal conductivity, enabling them to effectively minimize heat loss or gain within the heat exchanger. Furthermore, insulating fire bricks exhibit remarkable resistance to thermal shock and can endure extreme temperatures, solidifying their reliability for heat exchanger applications. Ultimately, incorporating insulating fire bricks in heat exchangers can enhance energy efficiency and overall performance.

- Q: Can insulating fire bricks be used in lime plants?

- Indeed, insulating fire bricks have the capability to be utilized in lime plants. These bricks are uniquely crafted to possess a remarkably low thermal conductivity, thus enabling them to effectively impede the transfer of heat. In the context of lime plants, where elevated temperatures are necessary for the calcination process, insulating fire bricks can be employed to line the kilns and other zones exposed to high temperatures. By doing so, these bricks aid in the preservation of heat within the lime kilns, resulting in a reduction of energy loss and an enhancement of overall efficiency. Furthermore, insulating fire bricks possess resistance against chemical attacks and are able to endure the harsh conditions experienced in lime plants, rendering them a suitable and appropriate choice for this particular application.

- Q: Are insulating fire bricks chemically resistant?

- Insulating fire bricks exhibit a wide resistance to numerous substances chemically. These bricks are typically composed of top-notch refractory materials, including alumina, silica, or a combination of the two. These materials possess exceptional chemical resistance, thereby endowing insulating fire bricks with formidable protection against the corrosive effects of diverse chemicals. Nevertheless, it is essential to acknowledge that the chemical resistance of insulating fire bricks may vary depending on their distinct composition and manufacturing techniques. While they generally withstand most chemicals, there exists a possibility of certain aggressive chemicals or extreme circumstances potentially causing the degradation or erosion of the bricks over time. To guarantee the utmost chemical resistance of insulating fire bricks, it is advised to consult the manufacturer's specifications or seek expert counsel pertaining to specific applications. Such measures will ensure that the bricks are suitable for the intended chemical environment and will consistently perform as desired throughout their expected lifespan.

Send your message to us

Insulating Fire Clay Refractory Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.05

- Supply Capability:

- 1800 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords