Laticrete Fiberglass Mesh Reinforced Bituminous Waterproof Roofing Membrane Felt

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

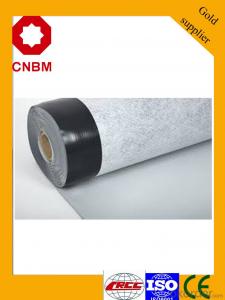

Roofing membrane,breathable roofing membrane,waterproof roofing membrane,permeable roofing membrane,membrane for underlay,roofing felt,waterproof roofing felt,Bituminous roofing felt,Bituminous membrane,Asphalt Felt,Bituminous felt,

Description:

It is designed for use as a type of underlay on roofs with tiles, slates or steel tiles. This underlay can be also used to provide extra security under tiles when sub-roof sheets are used. The edges have been reinforced in order to boost its tear resistance, improve the nail holds and enable the product to withstand rough treatment.

It has a glass fiber core that has been impregnated with bitumen. The core is coated on both sides with stabilised bitumen and the surface is coated with fine slate granules. The edges of this underlay has been reinforced with polypropylene felt to provide excellent tear resistance and good purchase for nails.

Specfications:

1/, Weight/sqm: 550gr, 750gr, 1200gr, 1500gr, etc;

2/, Roll size: 1X20m, 1X30m, etc;

3/, CE approved.

4/, Special requirements can be manufactured as client's requirements.

- Q: Why does the construction sector have no supervision on the use of fiberglass mesh?

- External thermal insulation needs a large amount of fiberglass mesh.

- Q: The difference between wet and dry gridding cloth for external wall thermal insulation

- With glass fiber woven fabric as base material, gridding cloth is dipped in and coated with highly resistant polymer emulsion, thus featured by good alkali resistance, flexibility and high tensile resistance in the bidirection of warp and weft. It is widely used for thermal insulation, water proofing and crack resistance of internal and external walls of buildings. With alkali or alkali free glass fiber yarn as raw material and woven glass fiber gridding cloth as the base material, exterior wall thermal insulation gridding cloth (glass fiber grid cloth) is a new type of alkali product made by coating acrylic copolymer liquid and drying. It is featured by stable structure, high intensity, good alkali resistance, anti-corrosion, crack resistance, best enhancing effect, easy construction and operation. It is a kind of new building materials for thermal insulation of external walls and mainly used for internal and external surface reinforcement and crack resistance in cement, gypsum, walls, buildings and other structures.

- Q: Should gridding cloth be added when painting the inside corner of infilled wall and concrete column or shear wall?

- It should be added, or crack may appear.

- Q: in the process of producing thermal insulation material mesh and the mesh production line, why do you burn the coal? What is the function of coal in the production process?

- thermal insulation material mesh is glass fiber cloth. Burning coal is mainly to fuse the glass and it is silk weaving cloth produced by the glass fusion wire drawing plussing the special liquid medicine.

- Q: What are the hazards of glass fiber to human body?

- That is to say, there will not be immediate harm, but there will be a potential crisis for the body for a long time

- Q: Is there a difference between a textile knife and a chemical fiber knife and a fiberglass cutter?

- First, make clear the difference between chemical fiber and glass fiber,

- Q: What is E fiberglass?

- The specific content of alkali metal oxides, the current provisions of China is not greater than 0.5%, generally around 1% abroad.

- Q: For puttying in decoration, anti-cracking fiberglass mesh or dacron cloth is widely used on walls. What are the correct constrcution order and method?

- If it is not sticked firmly, use white latex strip to attach bar-type anti-cracking cloth at the seams. Brush some white latex on anti-cracking cloth again.

- Q: What are fiberglass and fiberglass?

- According to fiber morphology and length, they can be divided into three broad categories:1. continuous glass fiber or textile glass fiber. The production method is mainly by making the melted glass bushing high-temperature material outflow, drum drawing multiple fiber high speed rotating beam and. After textile processing, it can be made into glass yarn, cloth, band, rope and roving and other products.2. fixed length glass fiber or glass long cotton. It is a messy single fiber, can be made into mats or yarn, wool yarn, cloth belt can also be made. Fixed length glass fiber is a high speed air jet or molten glass liquid into the fiber, and then cut into.3. glass wool. Glass wool is a glass fiber length shorter, tissue fluffy, similar in morphology to cotton, also known as the short glass cotton. Glass short cotton is processed by steam injection, centrifugal method, centrifugal injection and flame injection.

- Q: Should the wall be pasted with gridding cloth before painting?

- According to the processing, please check whether greasy layer has water resistance or powder removal. The cement mortar layer should be processed with adhesion agent which is used for solidifying. Then thick leveling materials are used for guarantying the stability of architectural surface durability by selecting wallpaper, latex paint and diatom ooze.

Send your message to us

Laticrete Fiberglass Mesh Reinforced Bituminous Waterproof Roofing Membrane Felt

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords