Self Adhesive Bitumen Waterproof Membrane for Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

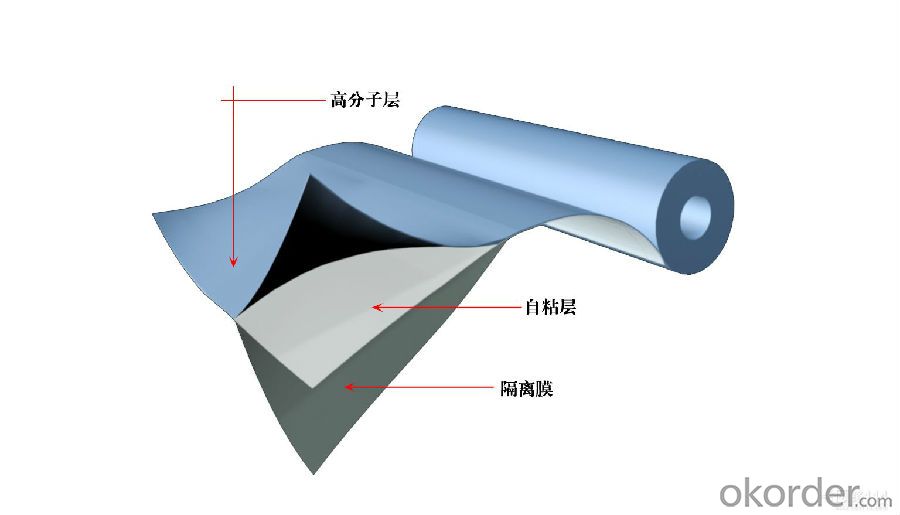

Self adhesive waterproofing material ismade by saturating the base in bitumen, or thermoplastic elastomer (such as styrene butadiene), reinforced with polyester or fiberglass, finishing the upward face with fine sands, mineral slates (or grains) or polythene membrane etc. It has the outstanding performance such as: convenient to apply, no environmental pollution etc. This product is consisting of two kinds: without reinforcement and polyester reinforcement.

Specification

Thickness | 3mm, 4mm, 5mm |

Width | 1m |

length | 7.5m, 10m, 15m, or on demand |

Base | Polyester or Fiberglass felt |

Surface | PE film, Aluminum foil, Yellow sand, Shale gravel(Schist), colored sand |

Type | could self-adhesive |

Notice | SBS modified bitumen membrane is specially applied in the cold district, APP modified bitumen membrane is more suitable for hot district with high temperature. could be self-adhesive modified bitumen membrane |

Advantages

1) Cold-applied construction with no open flame and self-adhesion without bonding agent make it safe, low- carbon, environmental, and economical.

2) Excellent adhesive performance guarantees the integrity of waterproof layer.

3) Good rubber elasticity, elongation and shear stress.

4) Good low-temperature property.

FAQ

1. Is sample available before place orders?

A: Yes, sample is ok.

2. How long is the dispatch period?

A: It will be around 20-30 days.

- Q: Are waterproofing membranes suitable for residential basements?

- Residential basements can indeed benefit from the use of waterproofing membranes. These membranes are specifically engineered to avert water infiltration and safeguard the basement against any harm caused by moisture. Whether applied on the interior or exterior walls, they create a formidable barrier against both water and dampness. This, in turn, helps to stave off problems like mold growth, water damage, and structural decay. With their excellent durability and ability to foster a dry and wholesome living space, waterproofing membranes emerge as a highly effective solution for residential basements.

- Q: Does a waterproofing membrane require any special considerations for installation in earthquake-prone areas?

- Yes, a waterproofing membrane does require special considerations for installation in earthquake-prone areas. In these areas, the ground is more susceptible to movement and shaking, which can significantly impact the integrity of the waterproofing system. Therefore, it becomes crucial to take additional precautions to ensure that the membrane is properly installed and capable of withstanding seismic activity. One important consideration is the selection of the waterproofing membrane itself. It is recommended to choose a membrane that has been specifically designed and tested to withstand seismic activity. These membranes are usually more flexible and have higher tensile strength to accommodate ground movement during earthquakes. Additionally, the installation process should be executed with utmost care and attention to detail. The membrane should be properly anchored or secured to the substrate using appropriate fasteners and adhesives. Reinforcement techniques such as the use of reinforcing fabric or mesh can also be employed to enhance the membrane's resistance to movement. Furthermore, it is essential to ensure that all seams and joints in the membrane are properly sealed and reinforced. Special attention should be given to areas that are more prone to movement, such as corners, edges, and penetrations. Using compatible and high-quality sealants or adhesives will help maintain the integrity of these vulnerable points. Regular inspections and maintenance are also crucial in earthquake-prone areas. Inspecting the membrane periodically for any signs of damage, such as cracks or separations, allows for early detection and timely repairs. Additionally, it is vital to have a contingency plan in place to address any potential damage that may occur during an earthquake, including emergency repair procedures. In summary, installing a waterproofing membrane in earthquake-prone areas requires careful consideration and adherence to specific guidelines. By selecting an appropriate membrane, properly anchoring and reinforcing it, ensuring proper sealing of seams and joints, and conducting regular inspections, the waterproofing system can be better prepared to withstand earthquakes and provide long-lasting protection against water intrusion.

- Q: Can a waterproofing membrane be used for shopping malls or commercial buildings?

- Indeed, shopping malls or commercial buildings can utilize a waterproofing membrane. In construction, waterproofing membranes serve as a prevalent method to safeguard structures from water-related harm. These membranes possess tailored designs that facilitate the creation of barriers against water infiltration, effectively preventing leaks and the accumulation of moisture. Through the application of a waterproofing membrane to the exterior of a building, the longevity and durability of the structure are safeguarded. Given the considerable surface areas of shopping malls and commercial buildings, which are often exposed to varying weather conditions, they become particularly susceptible to water damage. Consequently, employing a waterproofing membrane emerges as a highly efficient solution to shield these buildings and uphold their structural integrity.

- Q: How does a waterproofing membrane withstand freeze-thaw cycles?

- A waterproofing membrane is designed to withstand freeze-thaw cycles by being made of materials that are resistant to temperature changes and water infiltration. These membranes are typically composed of durable polymers such as polyurethane, polyethylene, or PVC, which have low permeability to water and can resist the expansion and contraction caused by freezing and thawing. During freeze-thaw cycles, water can enter small cracks and pores in a structure. When this water freezes, it expands, exerting pressure on the surrounding materials. This expansion can cause cracks to widen and weaken the structure, leading to water leakage and potential damage. However, a waterproofing membrane acts as a barrier, preventing water from penetrating the structure and reducing the potential for freeze-thaw damage. The membrane is installed on the exterior surface of the structure, forming a seamless and continuous layer that does not allow water to pass through. It adheres tightly to the surface and is flexible enough to accommodate the dimensional changes caused by temperature variations. Moreover, waterproofing membranes are often reinforced with other materials such as fabrics or meshes to enhance their strength and stability. These reinforcements further protect the membrane from damage during freeze-thaw cycles, ensuring its long-term effectiveness. In summary, a waterproofing membrane withstands freeze-thaw cycles by preventing water infiltration and resisting the expansion and contraction caused by freezing and thawing. Its composition, including durable polymers and reinforcements, makes it a reliable barrier against water penetration, reducing the risk of structural damage and maintaining the integrity of the protected surface.

- Q: Can a waterproofing membrane be used on below-grade structures, such as basements?

- Basements can benefit greatly from the use of a waterproofing membrane. Installing this membrane is highly recommended to avoid water infiltration and moisture problems. Acting as a barrier, the waterproofing membrane prevents water from seeping into the basement walls and floors. It is typically made of materials like bitumen, rubberized asphalt, or polyethylene, which are designed to be impermeable to water. The membrane can be applied either on the outside or inside of the basement walls and floors, creating a tight seal that prevents water damage, mold growth, and structural issues caused by water penetration. Therefore, it is essential to use a waterproofing membrane on basements and other below-grade structures to ensure a dry and safe living or storage area.

- Q: Can waterproofing membranes be used in wet areas like bathrooms?

- Waterproofing membranes are indeed suitable for wet areas such as bathrooms. It is strongly advised to utilize these membranes in bathroom spaces to prevent water damage and leaks. These membranes are specifically designed to form a barrier against moisture, guaranteeing that water does not infiltrate the bathroom's walls, floors, or other surfaces. By applying a waterproofing membrane, you can effectively safeguard the underlying structure from water damage, mold growth, and other issues caused by extended exposure to moisture. This is particularly crucial in wet areas like bathrooms where water is consistently present. Waterproofing membranes can be found in various forms, including sheet membranes, liquid membranes, and even pre-formed shower trays. They can be applied to walls, floors, shower enclosures, and other surfaces to create a tight seal against water. It is essential to correctly install and maintain the waterproofing membrane according to the manufacturer's guidelines to ensure its efficacy and durability. Therefore, if you are contemplating renovating or constructing a bathroom, it is highly recommended to use waterproofing membranes to guarantee a long-lasting and moisture-resistant space.

- Q: Can a waterproofing membrane be used for an underground structure?

- Yes, a waterproofing membrane can be used for an underground structure. A waterproofing membrane is a protective layer that is designed to prevent the penetration of water into a structure. It is commonly used on roofs, basements, and other areas that are prone to water infiltration. When used in an underground structure, such as a basement or foundation, a waterproofing membrane serves as a barrier against water that may be present in the surrounding soil or groundwater. It helps to prevent water seepage, which can cause damage to the structure and lead to issues such as mold growth or structural deterioration. The waterproofing membrane is typically applied to the exterior walls and the foundation of the underground structure to provide a watertight seal. It is important to select a high-quality membrane that is specifically designed for underground use and meets the necessary industry standards. Additionally, proper installation techniques, including surface preparation and sealing of seams, are crucial to ensure the effectiveness of the waterproofing membrane in an underground structure.

- Q: How much does a waterproofing membrane cost?

- The price of a waterproofing membrane can fluctuate based on various elements. Elements such as the type of membrane, the area's size that needs to be waterproofed, and the intricacy of the installation can all influence the cost. Typically, the cost of a waterproofing membrane can vary between $1 and $5 per square foot. However, this estimation is merely a rough approximation and the actual cost can be either higher or lower depending on the factors mentioned above. To illustrate, a basic sheet membrane composed of PVC or EPDM may fall on the lower end of the price spectrum, whereas a liquid-applied membrane or a more advanced system like a bentonite clay membrane could be on the higher end. Furthermore, the size of the area requiring waterproofing will have an impact on the cost. Larger areas will necessitate more materials, labor, and time, which can escalate the overall price. The complexity of the installation is another aspect to consider. If the area is difficult to access or necessitates extensive preparation work, such as the removal of existing materials or the repair of cracks, the cost may increase. It is advisable to seek guidance from a professional waterproofing contractor who can evaluate your specific requirements, provide an accurate estimate, and recommend the most suitable waterproofing membrane for your project.

- Q: Can a waterproofing membrane be used for loading dock levelers and pit walls?

- Indeed, loading dock levelers and pit walls can benefit from the utilization of a waterproofing membrane. These membranes are specifically engineered to offer a shielding barrier against the infiltration of moisture and water. Applying a waterproofing membrane to loading dock levelers and pit walls serves to counteract water seepage and the potential harm induced by moisture. This serves as a crucial measure, particularly in areas where water exposure is a considerable concern, such as loading docks and pits that experience constant exposure to rain, snow, or water from cleaning activities. The waterproofing membrane establishes an impervious barrier that ensures the foundational structures remain dry and safeguards them from possible water-related complications such as corrosion, mold proliferation, and deterioration.

- Q: Can a waterproofing membrane be used for green roofs?

- Indeed, a fundamental element of green roofs is the utilization of a waterproofing membrane. This membrane serves as a vital part of the green roof system, alongside a layer of vegetation and growing medium. Its primary purpose is to prevent any water infiltration into the building. Acting as a protective barrier, the waterproofing membrane shields the underlying structure from potential water damage. Its design is specifically engineered to endure continuous exposure to moisture and ensure no water permeates through to the building. Moreover, the membrane aids in retaining water within the green roof system, facilitating appropriate drainage and irrigation. As a result, the inclusion of a top-quality waterproofing membrane is indispensable for the successful installation and operation of a green roof.

Send your message to us

Self Adhesive Bitumen Waterproof Membrane for Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords