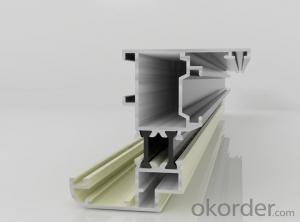

Factory Low Price Extruded Aluminum Heat Sink Profiles

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: Are aluminum profiles suitable for automotive heat exchangers?

- Automotive heat exchangers can effectively utilize aluminum profiles due to their numerous advantages. Firstly, aluminum possesses outstanding thermal conductivity, enabling efficient heat transfer between mediums. This quality allows aluminum heat exchangers to effectively dissipate heat generated by vehicle components such as the engine or transmission. Secondly, aluminum profiles are both lightweight and strong, making them a preferred option in the automotive industry. Weight reduction is crucial for improved fuel efficiency and performance, and aluminum heat exchangers contribute to this goal. By utilizing aluminum, overall weight is reduced, resulting in better handling, acceleration, and energy efficiency. Furthermore, aluminum exhibits high resistance to corrosion, even in harsh environments, making it highly suitable for automotive applications. This corrosion resistance ensures the durability and reliability of heat exchangers, reducing maintenance and replacement costs. Additionally, the manufacturing and formation of aluminum profiles into complex shapes is a simple task. This flexibility in design allows for customized heat exchanger designs that meet specific automotive requirements. The ability to efficiently utilize available space and maximize heat exchange surface area enhances overall performance. In conclusion, aluminum profiles are an excellent choice for automotive heat exchangers due to their exceptional thermal conductivity, lightweight yet strong properties, corrosion resistance, and design flexibility. These qualities make aluminum the ideal material for effectively managing heat in vehicles, resulting in improved performance, fuel efficiency, and durability.

- Q: This question asks for methods to guarantee the high quality of aluminum profiles used in a construction project.

- <p>To ensure high-quality aluminum profiles for your building project, start by selecting profiles from reputable manufacturers known for quality. Check for certifications such as ISO 9001 for quality management systems. Inspect the profiles for uniformity in thickness and color, and ensure they are free from defects like dents or scratches. Request third-party test reports to verify the strength and durability of the profiles. Additionally, consider the chemical composition and alloy type to ensure they meet the required specifications for your project. Always procure from suppliers who offer warranties and after-sales support.</p>

- Q: This question asks for guidance on selecting the appropriate aluminum profiles for a construction project.

- <p>Choosing the right aluminum profiles for your building project involves several steps. First, consider the specific requirements of your project, such as load-bearing capacity, aesthetic preferences, and environmental conditions. Consult with engineers or architects to determine the appropriate strength, size, and shape of the profiles. Next, evaluate the quality of the aluminum, ensuring it meets industry standards for durability and resistance to corrosion. Look for profiles with good thermal insulation properties and UV resistance to maintain performance over time. Finally, consider the cost-effectiveness and availability of the profiles, as well as the ease of installation and maintenance. Always opt for reputable suppliers to ensure you receive high-quality products that meet your project's needs.</p>

- Q: This question asks if it is possible to recycle aluminum profiles in a simple and effective manner.

- <p>Yes, aluminum profiles can be recycled easily and efficiently. Aluminum is one of the most recycled materials in the world due to its non-toxic nature and the energy efficiency of the recycling process. Recycling aluminum requires only 5% of the energy needed to produce new aluminum from raw materials. Additionally, aluminum can be recycled indefinitely without losing its properties, making it a highly sustainable material. The recycling process involves melting the aluminum, which is a relatively simple and cost-effective procedure compared to many other materials. This makes aluminum an ideal material for sustainable manufacturing and waste reduction strategies.</p>

- Q: This question asks for methods to ensure the reliable and durable installation of aluminum profiles.

- <p>To ensure the reliable and durable installation of aluminum profiles, follow these steps: Use high-quality aluminum materials that meet industry standards for strength and durability. Ensure proper alignment and level during installation to prevent warping or stress on the profiles. Use appropriate fasteners and adhesives recommended for aluminum to ensure a strong bond. Avoid over-tightening fasteners, which can cause deformation. Regularly inspect and maintain the profiles to check for signs of wear or damage, and address any issues promptly. This will help maintain the integrity and longevity of the aluminum profiles.</p>

- Q: Can aluminum profiles be used in display stand and podium manufacturing?

- Yes, aluminum profiles can definitely be used in display stand and podium manufacturing. Aluminum is a highly versatile and durable material that offers several advantages such as lightweight, corrosion resistance, and easy customization. It can be easily shaped and fabricated into various designs and sizes, making it suitable for creating aesthetically appealing and functional display stands and podiums. Additionally, aluminum profiles can also be an excellent choice for portable or temporary setups due to their portability and easy assembly.

- Q: Aluminum extrusion die, what material is better? Can reach long life, extruded products surface smooth and smooth?

- The main material used now is H13, which is the most common material usedThe problem of life not only with material, heat treatment with you, mold making, mold structure, relationship maintenance and other aspects in the use of Dongxin steel, specializing in the production of aluminum extrusion die material.

- Q: What is the terminology to explain the aluminum twist and bending and a sharp respectively.

- Curvature:1. longitudinal bending: the profile is placed on the platform, and when the weight is stable, the maximum gap between the bottom of the profile and the platform is measured along the length of the profile, that is, the longitudinal curvatureThe 2. longitudinal wave degree (or bend): the section on the platform, to achieve stability by self, the ruler will be 300mm long (or flat on the surface of the profile cutter) waves or hard along the length direction of a profile, profile measurement and rule (or ruler knife) between the maximum gap value that is, longitudinal wave degree (or bend).

- Q: Are aluminum profiles suitable for roofing systems?

- Indeed, roofing systems find aluminum profiles to be a suitable option. The lightweight and durable nature of aluminum make it a highly advantageous material for roofing purposes. Its exceptional resistance to corrosion makes it well-suited for different climatic conditions, guaranteeing long-lasting performance. Moreover, aluminum profiles possess remarkable thermal properties by reflecting heat and reducing energy consumption for cooling requirements. Not to mention, aluminum is easily manageable, allowing for adaptable designs and installations. In summary, the strength, durability, and aesthetic allure of aluminum profiles make them a favored selection for roofing systems.

- Q: What materials are used for aluminum profile packing?

- Aluminum packaging standard is generally pearl cotton and kraft paper packaging, but depends on the degree of product requirements,

Send your message to us

Factory Low Price Extruded Aluminum Heat Sink Profiles

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords