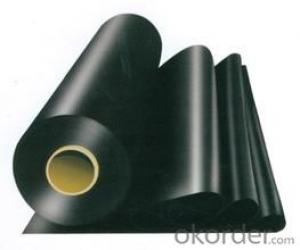

EPDM Rubber Sheet for Waterproofing with 1.5mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of EPDM Rubber Sheet with 1.5mm Thickness:

CE certification,in accordance with EN 13501-5:2005

homogenous epdm membrane.

ASTM standard D-7465,D-4637,

ISO9001 ISO14001

1.5mm epdm rubber roofing

EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is designed for waterproofing of exposed and non-exposed applications. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

Features of EPDM Rubber Sheet with 1.5mm Thickness:

Excellent weatherability, durability and size stability.

Good adaptability to high and low temperature, UV resistant and anti-corrosion.

High tensile strength and good elongation, accommodating substrate movement.

Easy installation, environment friendly.

Good rooting penetration resistance.

Service life up to 50 years.

Applications of EPDM Rubber Sheet with 1.5mm Thickness:

Subways, tunnels, roofs, basement.

Industrial and civil building waterproofing, like water reservior, bridge, dam, etc.

Geosynthetic liner for swimming pool, channels, irrigation system

Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

Technical Data of EPDM Rubber Sheet with 1.5mm Thickness:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

- Q: Can a waterproofing membrane be used on precast nickel surfaces?

- Yes, a waterproofing membrane can be used on precast nickel surfaces. Waterproofing membranes are designed to create a barrier against moisture and prevent water penetration. They can be applied to various surfaces, including concrete, metal, and even nickel. However, it is important to ensure that the waterproofing membrane is suitable for use on nickel surfaces and is compatible with the specific type of precast nickel being used. It is recommended to consult with a professional waterproofing contractor or the manufacturer of the membrane for guidance on the specific application and to ensure proper adhesion and effectiveness of the membrane on precast nickel surfaces.

- Q: Can a waterproofing membrane be used in conjunction with energy-efficient building designs?

- Yes, a waterproofing membrane can be used in conjunction with energy-efficient building designs. In fact, incorporating a waterproofing membrane into the construction of an energy-efficient building can provide several benefits. Firstly, a waterproofing membrane helps to protect the building envelope from water infiltration, which is critical for maintaining the integrity and longevity of the structure. By preventing water damage, the building can avoid costly repairs and potential energy losses caused by moisture intrusion. Additionally, a well-designed waterproofing system can contribute to the energy efficiency of the building by reducing the need for mechanical heating and cooling. By preventing moisture from entering the building envelope, the waterproofing membrane helps to maintain a consistent indoor temperature, reducing the load on HVAC systems and improving energy efficiency. Furthermore, certain types of waterproofing membranes, such as those with reflective or heat-resistant properties, can also contribute to energy savings by reducing heat transfer through the building envelope. These membranes reflect solar radiation, reducing the amount of heat absorbed by the building, and thus decreasing the demand for cooling. Lastly, waterproofing membranes can be integrated with other energy-efficient building components, such as green roofs or rainwater harvesting systems. These systems can help to further reduce energy consumption by providing insulation, reducing stormwater runoff, and promoting sustainable water management practices. Overall, incorporating a waterproofing membrane into an energy-efficient building design can enhance both the durability and energy performance of the structure. It offers protection against water damage, reduces the load on mechanical systems, and can be integrated with other sustainable features, making it a valuable component of energy-efficient building designs.

- Q: Can a waterproofing membrane be used on lead surfaces?

- Indeed, lead surfaces commonly exist within the roofing industry, where it is feasible to employ a waterproofing membrane. This application aids in safeguarding against undesirable consequences such as water damage and leaks. It is crucial to ascertain the compatibility of the waterproofing membrane with lead, as certain membranes may induce reactions or deterioration of the lead material. Moreover, adherence to appropriate surface preparation and installation techniques is necessary to achieve a reliable and efficient waterproofing solution. Consulting with a professional or manufacturer to obtain specific product recommendations and installation guidelines is highly advised.

- Q: Can a waterproofing membrane prevent leaks from occurring?

- Preventing leaks is indeed possible with the use of a waterproofing membrane. This membrane is a thin material layer that, when applied to a surface, renders it completely impervious to water. Its purpose is to serve as a barrier, effectively stopping water from seeping through and causing any leaks. With correct installation and ongoing maintenance, a waterproofing membrane can provide reliable protection against water damage for a variety of structures, such as roofs, basements, bathrooms, and foundations. It is specifically designed to withstand the forces of nature, including rain, snow, and moisture, thus greatly reducing the likelihood of leaks and water infiltration. However, it is worth noting that the efficacy of a waterproofing membrane also relies on the quality of the product, proper installation procedures, and regular maintenance.

- Q: Can waterproofing membranes be used on balconies?

- Yes, waterproofing membranes can be used on balconies. Waterproofing membranes are specifically designed to provide a protective barrier against water penetration, making them an ideal solution for balconies that are exposed to weather elements such as rain, snow, and moisture. These membranes are typically applied to the surface of the balcony to create a seamless, watertight seal, preventing water from seeping through and causing damage to the underlying structure. The use of waterproofing membranes on balconies helps to extend their lifespan, reduce maintenance costs, and ensure the overall durability and functionality of the balcony.

- Q: Can a waterproofing membrane be used in conjunction with expansion joint systems?

- The use of a waterproofing membrane can be combined with expansion joint systems. These membranes are frequently employed to prevent the infiltration of water and safeguard structures against moisture damage. In contrast, expansion joint systems are put in place to enable movement and accommodate thermal expansion and contraction in structures. By utilizing both a waterproofing membrane and expansion joint systems, it is feasible to provide both waterproofing and movement accommodation in a structure. This guarantees that the structure is shielded from water damage while still permitting necessary movement. It is crucial to design and install both the waterproofing membrane and the expansion joint system properly to ensure their compatibility and effectiveness.

- Q: Can a waterproofing membrane be used for food processing facilities?

- Yes, a waterproofing membrane can be used for food processing facilities. These membranes are specifically designed to prevent water penetration and can be installed in areas where food is processed to ensure a hygienic and moisture-resistant environment.

- Q: Can a waterproofing membrane be used for museums or art galleries?

- Yes, a waterproofing membrane can be used for museums or art galleries. Waterproofing membranes are commonly used in various industries, including construction, to protect buildings from water damage. In the case of museums or art galleries, where valuable artifacts or artwork are housed, it is crucial to maintain a controlled environment to prevent any water-related issues such as leaks, moisture, or humidity. A waterproofing membrane can be applied to the walls, floors, or even roofs of these establishments to create a barrier against water intrusion. It helps in preventing water from seeping through the building structure, protecting the artwork from potential damage. Additionally, a waterproofing membrane can also aid in controlling the humidity levels within the museum or art gallery. By reducing moisture penetration, it helps maintain a stable environment, crucial for preserving delicate artwork or artifacts that are sensitive to humidity fluctuations. Moreover, waterproofing membranes come in various types, allowing for customization based on the specific requirements of the museum or art gallery. Some membranes are designed to withstand high water pressure, making them suitable for areas prone to heavy rainfall or potential flooding. Ultimately, using a waterproofing membrane in museums or art galleries is an effective measure to safeguard the valuable contents of these establishments, preserving them for future generations to enjoy.

- Q: Does a waterproofing membrane require any special precautions during installation?

- During the installation of a waterproofing membrane, certain precautions must be taken into account. Here are some important factors to consider: 1. Preparation of the Surface: Prior to installing the waterproofing membrane, it is essential to ensure that the surface is clean, dry, and free from any debris or loose particles. This may involve thorough cleaning or repairing any existing cracks or damages on the surface. 2. Compatibility of the Adhesive: It is crucial to use the appropriate adhesive or sealant that is compatible with the specific type of waterproofing membrane being installed. Using an incompatible adhesive can result in poor adhesion, compromising the effectiveness of the waterproofing system. 3. Proper Application Technique: The manufacturer's guidelines should be followed when installing the membrane, including specific instructions on temperature, humidity, and application technique. It is important to carefully adhere to these instructions to ensure proper adhesion and performance. 4. Sealing of Seams and Joints: Special attention should be given to seams and joints, as these areas are more susceptible to water penetration. It is necessary to correctly seal and reinforce these areas using the recommended sealants or tapes provided by the manufacturer. 5. Quality Control: Regular quality control checks should be conducted during installation to ensure that the membrane is being installed correctly and to promptly identify and address any potential issues or defects. In conclusion, by adhering to the manufacturer's instructions and paying close attention to the specific details of the installation process, the waterproofing membrane can be installed correctly and provide effective protection against water intrusion.

- Q: Can a waterproofing membrane be applied in cold weather conditions?

- Applying a waterproofing membrane in cold weather is possible, but the temperature range may differ depending on the product and manufacturer guidelines. Certain membranes can endure cold temperatures and be applied as low as -20 degrees Celsius (-4 degrees Fahrenheit), while others may have a higher minimum application temperature. Following the manufacturer's instructions is crucial, as well as ensuring the surface is adequately prepared and free from ice, snow, or moisture. Consulting with an experienced professional contractor who has worked with waterproofing membranes in cold weather conditions is also recommended for optimal results.

Send your message to us

EPDM Rubber Sheet for Waterproofing with 1.5mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords