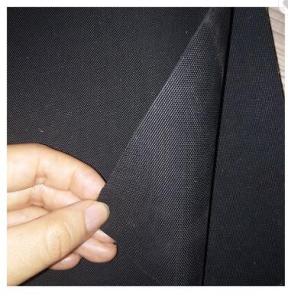

EPDM Waterproof Rubber Sheet for Roofing Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Waterproof Rubber Sheet for Roofing Industry:

1. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of Waterproof Rubber Sheet for Roofing Industry:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Application of EPDM Waterproof Rubber Sheet for Roofing Industry:

1) Roofs, Basement, Toilet

2) Industrial and civil building waterproofing

3) Geo-synthetic liner for swimming pool, channels, irrigation system

4) Especially suit for projects with high requirements in durability, anti-corrosion and deformation

Technical Parameters of EPDM Waterproof Rubber Sheet for Roofing Industry:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

2. What is your main market?

Our EPDM Waterproof Membrane for Roofing Industry sells very well in USA, United Kingdom, Austrilia, Canada, Japan, Pakistan, etc.

3. What is your advantage for EPDM Waterproof Membrane for Roofing Industry ?

With the most advanced production line, our good quality is based on superior material imported from America.

- Q: Can a waterproofing membrane be used on cinder block surfaces?

- Yes, a waterproofing membrane can be used on cinder block surfaces. Cinder blocks are porous materials that can absorb water, so applying a waterproofing membrane can help prevent moisture from penetrating the surface and causing damage. The membrane acts as a barrier, preventing water from infiltrating the cinder blocks and protecting them from moisture-related issues such as mold, mildew, and deterioration. It is important to properly prepare the cinder block surface before applying the membrane to ensure proper adhesion and effectiveness. Additionally, choosing a waterproofing membrane specifically designed for cinder block surfaces will provide the best results.

- Q: Can a waterproofing membrane be used on bridges?

- Bridges can indeed benefit from the application of a waterproofing membrane. It is quite common to utilize waterproofing membranes during bridge construction and rehabilitation projects in order to safeguard the bridge deck against water infiltration. These membranes are specifically designed to create a seamless and robust barrier, effectively preventing water from reaching the underlying bridge structure. By implementing a waterproofing membrane on the bridge deck, it significantly prolongs the lifespan of the bridge by minimizing moisture-induced damage and thwarting the corrosion of reinforcement steel. Moreover, these membranes also aid in diminishing the potential for freeze-thaw damage, cracking, and deterioration of the bridge deck. All in all, incorporating a waterproofing membrane on bridges is an efficacious approach to ensure the enduring durability and structural integrity of the bridge.

- Q: Can a waterproofing membrane be used on different types of surfaces, such as concrete, wood, or metal?

- Yes, a waterproofing membrane can be used on different types of surfaces including concrete, wood, and metal. Waterproofing membranes are designed to provide a protective barrier against moisture and can adhere to various surfaces, ensuring effective waterproofing regardless of the material.

- Q: Can a waterproofing membrane be painted or covered with a protective layer?

- Yes, a waterproofing membrane can be painted or covered with a protective layer. However, it is important to choose the right type of paint or protective layer that is specifically designed for use with waterproofing membranes. This ensures that the integrity of the membrane is not compromised and that it continues to provide effective protection against water damage. It is also important to follow the manufacturer's guidelines and recommendations when applying paint or a protective layer to the membrane. This may include proper surface preparation, application techniques, and maintenance instructions. By following these guidelines, the waterproofing membrane can be painted or covered with a protective layer without compromising its effectiveness.

- Q: Can a waterproofing membrane prevent mold and mildew growth?

- A waterproofing membrane has the ability to prevent the growth of mold and mildew. Mold and mildew thrive in areas that are damp and moist, but waterproofing membranes act as a barrier that stops water from seeping into the surfaces below. By ensuring that the area remains dry, the membrane reduces the conditions needed for mold and mildew to grow. Furthermore, certain waterproofing membranes are specifically designed to have antimicrobial properties, which further hinder the growth of mold and mildew. However, it is important to remember that while a waterproofing membrane can help prevent mold and mildew growth, it is not a guaranteed solution. Proper ventilation and maintenance are also essential in preventing these problems.

- Q: Can a waterproofing membrane be used in elevator pits?

- Yes, a waterproofing membrane can be used in elevator pits. Elevator pits are vulnerable to water damage and moisture accumulation, so applying a waterproofing membrane can help prevent water intrusion and protect the elevator components from potential damage.

- Q: Can a waterproofing membrane be applied on top of existing surfaces?

- Indeed, one can indeed apply a waterproofing membrane onto preexisting surfaces. Nevertheless, it is crucial to guarantee that said surface is clean, dry, and in proper condition prior to membrane application. Prior to installation, any cracks, holes, or damages must be repaired. Moreover, the nature of the existing surface may impact the type of waterproofing membrane that can be utilized. It is highly advised to seek guidance from a proficient waterproofing contractor to ascertain the most appropriate membrane for the given surface and circumstances.

- Q: Does a waterproofing membrane prevent water infiltration through concrete or other building materials?

- Yes, a waterproofing membrane is designed to prevent water infiltration through concrete or other building materials. It acts as a protective barrier that is applied to the surface of the material, forming a water-resistant layer. This membrane can be made from various materials such as bitumen, rubberized asphalt, or liquid polymers. When properly installed, it can effectively prevent water from seeping through the concrete or other building materials, thus protecting the structure from potential water damage or moisture-related issues.

- Q: Are waterproofing membranes resistant to acid exposure?

- Yes, waterproofing membranes are generally resistant to acid exposure. They are designed to provide a barrier against water and other corrosive substances, including acids. However, the level of resistance may vary depending on the specific type and quality of the membrane used.

- Q: Can a waterproofing membrane be used on below-grade walls?

- Yes, a waterproofing membrane can be used on below-grade walls to prevent water infiltration and moisture damage.

Send your message to us

EPDM Waterproof Rubber Sheet for Roofing Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords