EPDM Rubber Sheet for Waterproofing Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

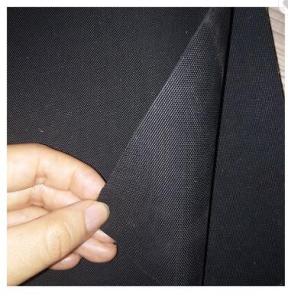

Introduciton of EPDM Rubber Sheet for Waterproofing Industry:

This waterproof coiled material is of high elasticity with best performance among high polymer waterproof coiled material in the world.It is also the most typical one in the world.Waterproof coiled material made of ternary ethylenepropylene rubber of KINTOPbrand is produced with the use of the most advanced continuous extrusion and vulcanization technology and related equipments which are specially designed for production of such product.It is good in compactness,without bubble and performance difference in length and breadth,performances reach or exceed the demands of GB18173.1-2012 standard.

Features of EPDM Rubber Sheet for Waterproofing Industry:

Excellent weatherability, durability and size stability.

Good adaptability to high and low temperature, UV resistant and anti-corrosion.

High tensile strength and good elongation, accommodating substrate movement.

Easy installation, environment friendly.

Good rooting penetration resistance.

Service life up to 50 years.

Applications of EPDM Rubber Sheet for Waterproofing Industry:

Subways, tunnels, roofs, basement.

Industrial and civil building waterproofing, like water reservior, bridge, dam, etc.

Geosynthetic liner for swimming pool, channels, irrigation system

Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

Technical Data of EPDM Rubber Sheet for Waterproofing Industry:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

- Q: Can a waterproofing membrane be used in permanent or long-term structures?

- Yes, a waterproofing membrane can be used in permanent or long-term structures. Waterproofing membranes are designed to provide durable and long-lasting protection against water intrusion. They are commonly used in various construction applications such as basements, roofs, foundations, and underground structures to prevent water damage and leakage. These membranes are engineered to withstand the test of time and can effectively extend the lifespan of a structure by ensuring its integrity and preventing moisture-related issues.

- Q: Can a waterproofing membrane be used for historic preservation projects?

- Yes, a waterproofing membrane can be used for historic preservation projects. Historic buildings often require special attention to preserve their original architecture and materials. Waterproofing membranes can be applied to protect historic structures from water damage, which can lead to deterioration and decay. These membranes are designed to be flexible, durable, and long-lasting, making them suitable for use on historic buildings. They can be applied to roofs, walls, and foundations to prevent water infiltration and ensure the preservation of the building's structural integrity. However, it is important to consult with preservation experts and adhere to appropriate preservation guidelines to ensure that the use of a waterproofing membrane is compatible with the building's historical significance and does not compromise its authenticity.

- Q: Can a waterproofing membrane be used for plaza decks?

- Plaza decks necessitate safeguarding against water infiltration to avoid harm to the underlying structure. This is where the application of a waterproofing membrane comes into play. These membranes are specifically designed to create a barrier, preventing water from permeating the deck and causing issues like leaks, deterioration, and structural damage. Typically composed of materials such as bitumen, rubber, or polyurethane, these membranes boast high resistance against water penetration. By incorporating a waterproofing membrane onto a plaza deck, it ensures the deck remains impervious to water, thereby preserving the integrity of the entire structure. Furthermore, these membranes offer additional advantages such as UV resistance, durability, and easy maintenance, rendering them an ideal solution for plaza decks.

- Q: Can a waterproofing membrane be used on plywood surfaces?

- Yes, a waterproofing membrane can be used on plywood surfaces. The membrane acts as a barrier to prevent water penetration, protecting the plywood from moisture damage and extending its lifespan.

- Q: How are waterproofing membranes installed?

- Waterproofing membranes are typically installed by first preparing the surface to ensure it is clean and free of any debris. Then, the membrane is unrolled and cut to size, ensuring it covers the entire area that needs to be waterproofed. Next, the membrane is adhered to the surface using a specialized adhesive or heat welding, depending on the type of membrane being used. Finally, any seams or joints are properly sealed to ensure a watertight installation.

- Q: Can a waterproofing membrane be used on tunnels with fire protection systems?

- Yes, a waterproofing membrane can be used on tunnels with fire protection systems. In fact, it is often recommended to use a waterproofing membrane in conjunction with fire protection systems in tunnels to provide an additional layer of protection. The waterproofing membrane helps to prevent water infiltration into the tunnel, which can potentially damage the fire protection systems and compromise their effectiveness. By ensuring that the tunnel is watertight, the waterproofing membrane helps to maintain the integrity and functionality of the fire protection systems, allowing them to perform their intended function in case of fire. Additionally, the waterproofing membrane can also help to prevent the spread of fire by acting as a barrier against the passage of flames and smoke. However, it is important to ensure that the selected waterproofing membrane is compatible with the specific fire protection systems being used in the tunnel to ensure optimal performance and safety.

- Q: Can a waterproofing membrane be applied in cold weather or during winter months?

- Yes, a waterproofing membrane can be applied in cold weather or during winter months. However, it is important to follow the manufacturer's guidelines and use products specifically designed for cold weather applications. Cold weather may affect the curing time of the membrane, so it is recommended to take necessary precautions and allow sufficient time for proper curing to ensure the effectiveness of the waterproofing.

- Q: Can a waterproofing membrane be used in schools or educational buildings?

- Certainly, schools and educational buildings can certainly make use of waterproofing membranes. These membranes are specifically engineered to halt water infiltration and safeguard the structural integrity of the building against moisture-related harm. In educational settings, where numerous students and staff congregate, it becomes imperative to uphold a secure and hygienic environment. Waterproofing membranes can be effectively deployed in a variety of areas like basements, roofs, walls, and foundations to avert water seepage, dampness, and the proliferation of mold. By incorporating a waterproofing membrane into their infrastructure, schools can ensure the long-term sustainability of their buildings, safeguard valuable equipment and resources, and furnish a comfortable learning atmosphere for students and staff.

- Q: Can a waterproofing membrane be used for loading dock levelers and pit walls?

- Yes, a waterproofing membrane can be used for loading dock levelers and pit walls. Waterproofing membranes are designed to provide a protective barrier against moisture and water infiltration. By applying a waterproofing membrane to loading dock levelers and pit walls, it helps to prevent water seepage and potential damage caused by moisture. This is particularly important in areas where water exposure is a concern, such as loading docks and pits where there may be constant exposure to rain, snow, or water from cleaning activities. The waterproofing membrane creates a barrier that keeps the underlying structures dry and protects them from potential water-related issues, such as corrosion, mold growth, and deterioration.

- Q: Can a waterproofing membrane be used for a planter box wall?

- Indeed, a planter box wall can benefit from the application of a waterproofing membrane. This specialized membrane is specifically designed to create a barrier against water infiltration, making it an excellent choice for a planter box wall where moisture is present. By employing a waterproofing membrane on the interior surface of the planter box, one can effectively safeguard the wall against moisture-related harm and prevent water from seeping into the adjacent soil. This proactive measure not only prolongs the lifespan of the planter box but also mitigates the risk of water damage to the surrounding area. However, it is imperative to ensure that the chosen waterproofing membrane is compatible with the materials utilized in the construction of the planter box and to adhere to the manufacturer's instructions for proper installation.

Send your message to us

EPDM Rubber Sheet for Waterproofing Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords