EPDM roof /pond waterproof membrane with SGS ISO

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Coiled Rubber Waterproof Membrane for Ponds

1. Brief Introduction:

It is a kind of self-adhesive waterproof coiled material based on polymer rubber and superior asphalt, together with polyethylene film and aluminum foil as surface material or no film(Double-sided self-adhesive). And it adopts the package preventing-adhesion-isolation-layer package, and dividing into no fiber and polyester fiber two parts.The coiled material has perfect performances, simple operation, non-pollution and etc.

2. Characters:

1)Good flexibility, creep properties and malleability, and the superior adapting ability to the deformation of the primary stress generated.

2). Tight adhesion between waterproof layer and basic layer, no channeling water. Having self healing ability after piercing.

3).Operation without heating. And possessing the reliability of pasting by itself with super strong connection of sheet materialand adhesion of same base.

4). Convenient and safe operation, no pollution to the environment.

3.Specifications of EPDM Rubber Waterproof Membrane:

Material | EPDM Rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

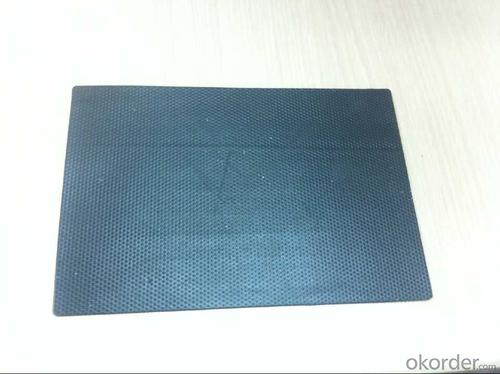

4. IMages of EPDM Rubber Waterproof Membrane:

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be applied to both interior and exterior surfaces?

- Yes, a waterproofing membrane can be applied to both interior and exterior surfaces. The purpose of a waterproofing membrane is to prevent water infiltration and protect the underlying surfaces. Whether it is applied on the inside or outside, the membrane serves the same purpose of creating a barrier against moisture. Interior waterproofing membranes are commonly used in basements and crawl spaces to prevent water seepage from the ground into the interior of the building. Exterior waterproofing membranes are typically applied on the exterior walls and foundations to prevent water penetration from rain, groundwater, or other external sources. Both types of membranes are designed to be durable, flexible, and resistant to water, ensuring the longevity and structural integrity of the surfaces they are applied to.

- Q: Does a waterproofing membrane require any curing time before it can be exposed to water?

- Yes, a waterproofing membrane does require a curing time before it can be exposed to water. The curing time allows the membrane to fully bond and develop its maximum strength, durability, and waterproofing properties. The exact curing time can vary depending on the type of membrane and the manufacturer's instructions. It is important to follow these instructions to ensure that the membrane is properly cured and can effectively protect against water intrusion. Failing to allow sufficient curing time can compromise the effectiveness of the membrane and may lead to leaks or other issues. Therefore, it is recommended to wait until the specified curing time has elapsed before exposing the waterproofing membrane to water.

- Q: Can a waterproofing membrane be used on roofs or only on vertical surfaces?

- A waterproofing membrane can be used on both roofs and vertical surfaces. It is a versatile solution that can effectively protect a variety of structures from water damage, including roofs, walls, and foundations.

- Q: Can a waterproofing membrane be used in areas with extreme weather conditions, such as hurricanes or snowstorms?

- Yes, a waterproofing membrane can be used in areas with extreme weather conditions, such as hurricanes or snowstorms. Waterproofing membranes are designed to provide a protective barrier against water infiltration and can effectively withstand various weather conditions. They are made from materials that are resistant to moisture and can be installed in different areas like roofs, basements, or foundations. In regions prone to hurricanes, waterproofing membranes can help prevent water damage by creating a barrier that keeps water out even during heavy rainfall or storm surges. These membranes are often reinforced and have high tensile strength to withstand the strong winds and pressure associated with hurricanes. Similarly, in areas with heavy snowstorms, waterproofing membranes can help prevent water intrusion caused by melting snow or ice dams. They are designed to be flexible and resistant to extreme temperatures, ensuring that they maintain their integrity and prevent leaks even in freezing conditions. However, it is important to choose the right type of waterproofing membrane suitable for the specific weather conditions in the area. Different membranes have varying levels of resistance to extreme weather, so it is advisable to consult with a professional to determine the most appropriate membrane for the specific climate and weather patterns. Additionally, proper installation and regular maintenance are crucial to ensure the longevity and effectiveness of the waterproofing system in extreme weather conditions.

- Q: Can a waterproofing membrane be used for residential buildings or homes?

- Yes, a waterproofing membrane can be used for residential buildings or homes. Waterproofing membranes are commonly used in construction to prevent water penetration and protect the building's structure and interior from moisture damage. They can be applied to various areas such as basements, roofs, foundations, and bathrooms, among others. By creating a barrier against water, these membranes help to prevent leaks, mold growth, and damage to the building materials. Therefore, using a waterproofing membrane is an effective way to ensure the longevity and durability of residential buildings or homes.

- Q: Can a waterproofing membrane be installed by a DIYer?

- Installing a waterproofing membrane can be done by someone who wants to do it themselves. However, it is important to keep in mind that the installation process can be complicated and requires careful attention to detail. It is crucial to thoroughly understand the instructions and guidelines provided by the manufacturer before attempting the installation. In addition, it is essential to properly prepare the surface in order to have a successful installation. This may involve cleaning, leveling, and priming the surface to ensure that the membrane adheres correctly. It is also important to choose the appropriate type and thickness of membrane for the specific application. Moreover, DIYers should have the necessary tools and equipment, like a trowel or roller, to apply the membrane accurately. Depending on the specific membrane and installation method, specialized tools may also be required in some cases. Considering safety measures is also important. It is recommended to wear protective gear and work in a well-ventilated area. Some waterproofing membranes may involve the use of hazardous chemicals, so it is crucial to follow all safety instructions provided by the manufacturer. If you are uncertain about your ability to properly install a waterproofing membrane, it is advisable to seek advice from a professional contractor who specializes in waterproofing. They have the knowledge and expertise to ensure a correct installation that will effectively protect your property from water damage.

- Q: Can a waterproofing membrane be used for bridge decks?

- Yes, a waterproofing membrane can be used for bridge decks. Waterproofing membranes are commonly used in bridge construction to protect the bridge deck from moisture, preventing water damage and increasing the lifespan of the bridge.

- Q: Can a waterproofing membrane be used on elevator pits?

- Yes, a waterproofing membrane can be used on elevator pits. Elevator pits are vulnerable to water damage due to their location below ground level and the potential for water infiltration. Installing a waterproofing membrane in the elevator pit can help protect the structure from water damage and prevent issues such as corrosion, mold growth, and deterioration. The membrane acts as a barrier, preventing water from seeping into the pit and causing damage to the elevator equipment or the surrounding structure. It is important to select a waterproofing membrane specifically designed for below-grade applications and to ensure proper installation to achieve effective waterproofing in elevator pits.

- Q: Can a waterproofing membrane be used on stadium seating areas?

- Indeed, stadium seating areas can benefit from the application of a waterproofing membrane. Typically utilized to shield structures from water-related harm, such as roofs, basements, and decks, waterproofing membranes prove invaluable. Stadium seating areas, being frequently exposed to the elements like rain and snow, are susceptible to water damage if not adequately safeguarded. The implementation of a waterproofing membrane effectively thwarts water infiltration, thereby averting potential predicaments including mold proliferation, material deterioration, and structural impairment. It is crucial to select a top-notch waterproofing membrane specifically formulated for outdoor usage, capable of enduring heavy foot traffic, thus guaranteeing enduring protection for the stadium seating areas.

- Q: Can a waterproofing membrane be used for industrial applications?

- Yes, a waterproofing membrane can be used for industrial applications. Waterproofing membranes are designed to provide a barrier against water penetration and can be utilized in various industrial settings such as factories, warehouses, and manufacturing facilities to protect against water damage and maintain the integrity of the infrastructure.

Send your message to us

EPDM roof /pond waterproof membrane with SGS ISO

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords