EPDM roof pond waterproof membrane with SGS ISO

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Coiled Rubber Waterproof Membrane for Ponds

Description Of EPDM Rubber Waterproof Membrane:

1. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Rubber Waterproof Membrane:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Specifications of EPDM Rubber Waterproof Membrane:

Material | EPDM Rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of EPDM Rubber Waterproof Membrane:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

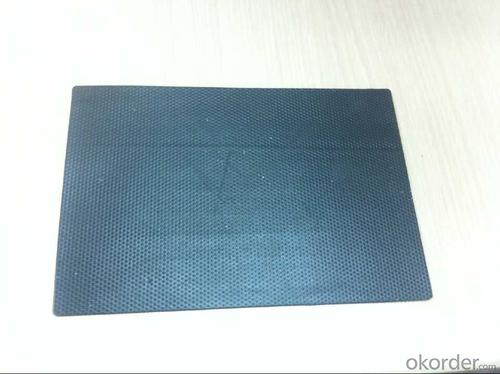

IMages of EPDM Rubber Waterproof Membrane:

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: APP selection of asphalt waterproofing membrane selection points

- 1, I type polyester tire or glass fiber tire modified asphalt waterproofing membrane PET higher heat resistance, but low temperature flexibility is poor. Suitable for non-cold areas for general construction works of the roof waterproof layer. The waterproofing material of the upper surface material of polyethylene film or fine sand shall not be exposed.

- Q: Can a waterproofing membrane be used in temporary or temporary structures?

- Yes, a waterproofing membrane can be used in temporary or temporary structures. Waterproofing membranes are designed to provide a protective barrier against water penetration, which is essential in preventing moisture damage in any type of building structure. Whether it is a permanent or temporary structure, such as a temporary shelter, tent, or temporary construction site, a waterproofing membrane can be applied to ensure water resistance and protection. It is important to choose a waterproofing membrane that is suitable for the specific needs of the temporary structure and follow proper installation guidelines to ensure its effectiveness.

- Q: Can a waterproofing membrane be used for laboratories or research centers?

- Laboratories or research centers can benefit greatly from utilizing a waterproofing membrane. These membranes are specifically designed to create a barrier against water and moisture, effectively preventing any infiltration that could potentially damage the structure. Given the presence of sensitive equipment, valuable specimens, and crucial data in these environments, it becomes imperative to uphold a controlled atmosphere that is completely free from any moisture. To ensure that water leaks do not occur, a waterproofing membrane can be applied to various surfaces, including floors, walls, and roofs. This application serves to safeguard the equipment, ward off potential hazards, and preserve a safe working environment. Moreover, the presence of a waterproofing membrane aids in the prevention of mold growth, which is vital for maintaining optimal air quality within laboratories and research centers. Ultimately, opting for a waterproofing membrane is a wise decision that guarantees the integrity and functionality of laboratories and research centers.

- Q: Polyurethane and SBS membrane waterproof

- SBS membrane, also known as modified asphalt waterproofing membrane, asphalt waterproof material; ?Polyurethane is rubber and plastic mine waterproof material;

- Q: Can a waterproofing membrane be used for an industrial facility?

- Yes, a waterproofing membrane can be used for an industrial facility. It provides a protective barrier against water intrusion, preventing potential damage and ensuring the integrity of the facility's structure.

- Q: Can a waterproofing membrane be used on tunnels with fire protection systems?

- Yes, a waterproofing membrane can be used on tunnels with fire protection systems. In fact, it is often recommended to use a waterproofing membrane in conjunction with fire protection systems in tunnels to provide an additional layer of protection. The waterproofing membrane helps to prevent water infiltration into the tunnel, which can potentially damage the fire protection systems and compromise their effectiveness. By ensuring that the tunnel is watertight, the waterproofing membrane helps to maintain the integrity and functionality of the fire protection systems, allowing them to perform their intended function in case of fire. Additionally, the waterproofing membrane can also help to prevent the spread of fire by acting as a barrier against the passage of flames and smoke. However, it is important to ensure that the selected waterproofing membrane is compatible with the specific fire protection systems being used in the tunnel to ensure optimal performance and safety.

- Q: Can a waterproofing membrane be used on tunnels?

- Yes, a waterproofing membrane can be used on tunnels. Tunnels are often subjected to high levels of moisture, groundwater infiltration, and potential leaks. Therefore, it is crucial to protect them from water damage and ensure their long-term structural integrity. Waterproofing membranes are commonly used in tunnel construction to prevent water penetration and provide an effective barrier against moisture. These membranes are designed to be durable, flexible, and resistant to various environmental conditions, making them suitable for use in tunnels. They can be applied to the tunnel walls, roof, and floor to create a waterproof seal, ensuring that the tunnel remains dry and protected from water-related issues such as corrosion, deterioration, and mold growth. Additionally, waterproofing membranes can also help in reducing maintenance costs and extending the lifespan of the tunnel infrastructure.

- Q: Can a waterproofing membrane be used in conjunction with other waterproofing methods?

- Indeed, the utilization of a waterproofing membrane in conjunction with other waterproofing methods is possible. In fact, it is quite customary to amalgamate multiple waterproofing techniques in order to offer augmented defense against water intrusion. Primarily, waterproofing membranes are frequently employed as the main layer of waterproofing, serving as a shield against water infiltration. Nevertheless, these membranes can be further reinforced through the utilization of other approaches including sealants, coatings, or drainage systems. These supplementary methods aid in addressing specific vulnerabilities, such as cracks, joints, or areas susceptible to high water pressure. Through the amalgamation of various waterproofing techniques, it becomes feasible to establish a comprehensive and efficacious waterproofing system that provides utmost safeguarding against water damage.

- Q: Can a waterproofing membrane be used for food processing facilities?

- Yes, a waterproofing membrane can be used for food processing facilities. Waterproofing membranes are commonly used in various industries, including food processing, to ensure protection against water penetration and moisture damage. In food processing facilities, where hygiene and cleanliness are of utmost importance, waterproofing membranes can be applied to floors, walls, and ceilings to prevent water or other liquids from seeping into the building structure. Waterproofing membranes create a protective barrier that effectively seals the surfaces, preventing the growth of mold, mildew, and bacteria that can contaminate food products. They also help in maintaining a clean and dry environment, reducing the risk of slips, falls, and accidents caused by wet surfaces. Food processing facilities often deal with water-intensive processes such as cleaning, washing, and sanitizing, making it crucial to have a reliable waterproofing system in place. Additionally, waterproofing membranes can offer resistance to chemicals, oils, and other substances commonly used in food processing, ensuring long-term durability and protection. It is important to note that when selecting a waterproofing membrane for a food processing facility, it is necessary to choose a product that complies with industry standards and regulations. The membrane should be food-grade and certified safe for contact with food products to avoid any potential contamination risks. Overall, using a waterproofing membrane in food processing facilities can help maintain hygienic conditions, protect the building structure, and ensure compliance with health and safety regulations.

- Q: Are there any specific safety precautions to consider when installing a waterproofing membrane?

- Yes, there are several safety precautions to consider when installing a waterproofing membrane. Firstly, it is important to ensure that all necessary personal protective equipment (PPE) is used by the installation team. This may include gloves, safety glasses, and appropriate footwear to prevent any injuries or exposure to hazardous materials. Additionally, it is crucial to work in a well-ventilated area to avoid inhalation of fumes or vapors emitted during the installation process. If working in a confined space, proper measures should be taken to ensure adequate ventilation and the use of proper respiratory protection if necessary. Furthermore, it is important to follow the manufacturer's instructions and guidelines for the specific waterproofing membrane being installed. This includes understanding any potential hazards associated with the product, such as flammability or toxicity, and taking necessary precautions to prevent accidents or exposure. Another safety consideration is to ensure that the installation area is properly prepared before beginning the process. This may involve removing any debris, cleaning the surface, and addressing any potential hazards or obstacles that could pose a risk to the installation team. Lastly, it is important to have a designated safety plan in place, including emergency procedures and first aid kits readily available in case of accidents or injuries. Regular safety inspections and monitoring throughout the installation process are also recommended to identify and address any potential safety risks promptly. By following these safety precautions, the installation of a waterproofing membrane can be carried out safely and effectively, minimizing the risk of accidents or injuries.

Send your message to us

EPDM roof pond waterproof membrane with SGS ISO

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords