Dual Plate Wafer Check Valve/Oblea de Doble Placa Valvula de Retencion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Plywood case or buyer request |

| Delivery Detail: | Negotiation |

Specifications

1. Size: 2"-48"

2. Pressure: 150~2500LB

3. Material: WCB,WC6, WC9, C5, C12, CF8M, CF3, CF3M, ETC.

4. STD:API6D, ASME, JIS, BS

DUAL PLATE WAFER CHECK VALVE

1 | SIZE | (INCH) 1/2” 1” 2” 3” 4” 6” 8” 10” ....48” (MM) 15, 25, 50, 80, 100, 125, 150, 200, 250, ...1200 |

2 | PRESSURE | (CLASS) 150, 300, 600, 800, 900, 1500, 2500 (MPA) 1.0, 1.6, 2.5, 4.0, 6.4, 10, 13, 15, 25, 42 |

3 | BODY MATERIAL | A216WCB, , SS316, SS304, SS316L, CF8C, ETC CARBON STEEL, STAINLESS STEEL, DUPLEX STEEL, ALLOY, ETC |

4 | STANDARD | BS, ASME, API, DIN, JIS, GOST,EU, ETC |

5 | ||

6 | CONNECTION | RF FALNGE, RTJ FALNGE, BW, SW, NPT, THREADED, WAFER, LUG, ETC |

7 | MEDIUM | CORROSIVE ENVIRONMENT, OIL, GAS, WATER, ETC. |

8 | WARRANTY | 12 MONTH |

1. Design & Manufacture Std.: API594, ASME B16.34, API 6D, JISB2074-JISB2084, BS1868

2. Face to Face Std.:ASMEB16.10, API 6D, JISB2002, DIN3202, EN558

3.Test Standard: API598, API 6D JISB2003

Features:

1. Small and light, Tightly sealed. Less expensive than swing check valve.

2. Two torsion springs are used excerting on each of the pair valve plate,which close

the plate quickly and automaticlly.

3. The quick-close action prevent the meidum from flowing back and eliminates water hammer effectly.

4. Can be installed both horizontaly and vertical on pipeline.

5. Safe and reliable in operation, high interference-resistance.

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

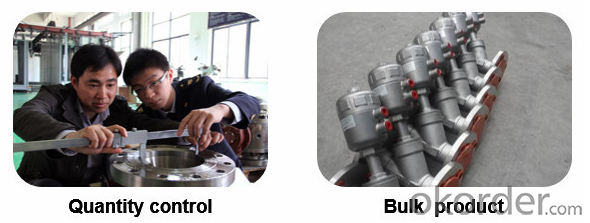

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Check valve h42h-dn80 what does that mean?

- According to the provisions of the JB/T 308-2004 valve type programming method:H = check valve4 = connection: flange2 = structure form: vertical lifting typeH = sealing surface material: Cr13 stainless steelDN80== nominal diameter: 80mm

- Q: What is the difference between the check valve rcvx and SFCV?

- SFCV rubber check valve parts design mainly by the body, valve cover and rubber valve composed of three major parts. Its main features are: rubber valve in the valve by the steel plate, steel bar and reinforced nylon cloth as the substrate, the outer rubber covered, the valve switch life of up to 1 million times. H44X (SFCV) series rubber check valves adopt full flow area design. They have the characteristics of small head loss, easy accumulation of debris, easy maintenance and so on. H44X (SFCV) series rubber check valve is mainly suitable for horizontal installation of water supply and drainage system. It can be installed at the water outlet of the pump to prevent backflow and water hammer damaging the pump. H44X (SFCV) series rubber check valves can also be installed on the bypass pipe of the reservoir inlet and outlet to prevent backflow of water to the water supply system. Check valves are generally applicable to clean media and are not suitable for media containing solids and viscosity.Analysis of the main characteristics of RCVX rubber valve check valve: the valve body, valve cover, valve and spring, mainly used for pipeline industry departments of water supply and drainage system, oil and chemical exports, to prevent the media counter. Due to the design of the sealing ring of the product, the closing time is short, and the water hammer pressure can be reduced. The valve is made of nitrile rubber and steel plate by high temperature. It is resistant to erosion and has good sealing performance. The product structure is simple, and the maintenance, maintenance and transportation are very convenient.

- Q: Are the common check valves stand upright or horizontally installed?

- 2. swing check valves are generally installed on horizontal or vertical or inclined pipes.

- Q: What type of check valve is the h61y-40 check valve?

- Two, swing check valve: the valve swing check valve cylindrical disk-shaped, around the seat of the shaft for rotation channel, because the valve channel into a streamlined, flow resistance than the small valve lift check, suitable for large caliber occasions in low flow and no flow frequently change, but not for the pulsating flow, the sealing performance is less than lift. Swing check valve is divided into single, double, and most types of three, the three forms mainly by the valve bore points, the purpose is to prevent the media to stop flow or reverse flow, weakening the hydraulic impact. Three, compression type check valve: This valve is used as boiler water supply and steam cutting valve, it has lift check valve and stop valve or angle valve comprehensive function. In addition, there are - some do not apply to pump outlet check valve is installed, such as valve, spring-loaded check valve, Y type check valve check valve. Four disc check valve: disc check valve around the pin rotation in the valve seat.

- Q: Where can I find the good check valve?

- Northeast, I think the quality is better

- Q: Check valve h44h-25p what does that mean?

- H- check valve code4- flange connection4- rotary single structureH sealing material is Cr13 stainless steel25-25 kg pressure 2.5MPaP- stainless steel 304

- Q: What is the difference between the H44H check valve and the H41 check valve?

- Swing check valve H44HLift check valve H41HThe installation of check valves (Check, Valve) shall pay attention to the following items1. Do not allow the check valve to bear weight in the line.

- Q: Is there a check valve with a relief valve above?

- Over the excess pressure discharge, maintain protection of pipeline system valve. For reference!

- Q: Check valve authentication information

- Consult the manufacturer for more information.Canadian, Registration, Number, CRN certificationMany of the Check-All valves have also been registered in Canada (0C3651.5R1C). Under some special conditions in Canada, the use of some products requires a Canadian registration code CRN. Check-All is registered in all provinces and territories of canada. CRN testing and labeling requirements are required at the time of ordering. If you need valves containing CRN, consult your manufacturer.Hygienic standard for Sanitary Standards3AThe Check-All 3SC Series Check Valves comply with 3A hygiene standards for milk and milk products, vacuum eliminator and check valves, and the standard number is 58-01. Among other requirements, the standard requires 32 radium processing, with precise groove angle and depth, all for sanitary purposes.

- Q: Is it necessary to install a check valve in the piston refrigeration compressor?

- To solve this problem, we first need to know the working cycle of the piston compressor:1, compression process, suction valve closed, refrigerant gas in the cylinder from low pressure to high pressure process;2 the exhaust process, compression end, from the cylinder through the exhaust valve to exhaust pipe process;3, expansion process, exhaust end, exhaust valve closed, the piston from the bottom of the cylinder moving to the top of the cylinder process;4 suction process, suction valve opens, low-pressure refrigerant gas inhalation process of the cylinder;From the above piston engines don't seem to need what steps to open check valve. Because the suction valve and exhaust valve on the cylinder are constantly switching each other, the piston machine continues to inhale and exhaust the process. If only from the piston machine, there is no need to install a check valve.But to consider the whole refrigeration system, rather than a simple piston compressor, when the piston of more than 2 units must be horizontal pipeline in a single compressor exhaust pipe to the exhaust duct installed on the check valve and pipe installation is about

Send your message to us

Dual Plate Wafer Check Valve/Oblea de Doble Placa Valvula de Retencion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords