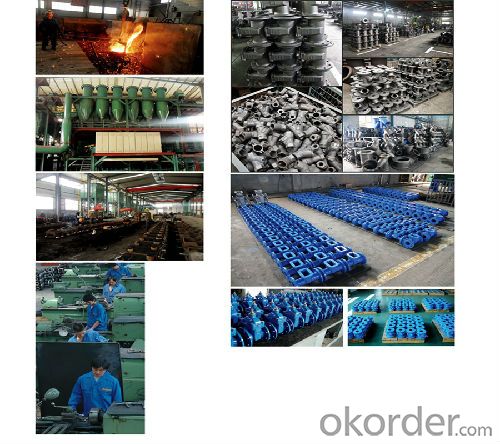

CHECK VALVE SWING DUCTILE IRON/ WCB DN40- DN600

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Details

Standard or Nonstandard: | Standard | Structure: | Check | Pressure: | High Pressure |

Power: | Hydraulic | Material: | Casting | Temperature of Media: | High Temperature |

Media: | Water | Port Size: | Flanged | Place of Origin: | China (Mainland) |

Model Number: | CVE | Brand Name: | CMAX | Application: | General |

Design Standard: | BS EN 593 | Color: | bule/red/customized | Connection Ends: | BS EN 1092 PN 10/PN16 |

Temperature: | -29°~+425° | Port size: | NPS 2"-42" | Working Pressure: | PN10/PN16 |

Temperature Pressure: | 0℃ to 80℃ | Coating: | Fusion Bonded Epoxy | Operation type: | water |

Surface: | Powder coating/Acid pickling/Paint |

Packaging & Delivery

Packaging Details: Standard export package or as per your requirements

Delivery Detail: 25 days from date of order

Technical Date | Material Specification | ||

Nominal Diameter | DN40-DN1000 | Valve Body | Cast Iron or Ductile Iron |

Nominal Pressure | PN10/PN16 |

Valve Disc | Cast Iron or Ductile Iron or Stainless Steel |

Operation Temperature | -40°C~225°C | ||

Flange Driling Standard | EN 1902-2 PN10/16 | Seal Material | EPDM OR NBR |

Suface Treatment | Painting |

Valve Spring |

Stainless Steel |

- Q: What's the use of the check valve?

- Check valve refers to rely on the flow of the media itself and automatically open and close the valve flap, used to prevent media backflow valve, also known as check valve, one-way valve, counter flow valve, and back pressure valve. The check valve belongs to an automatic valve, whose main function is to prevent the backflow of medium, prevent the reverse of pump and drive motor, and release the container medium.

- Q: Why is the water ring vacuum pump equipped with check valves?

- The check valve is a one-way valve, the instantaneous vacuum of the stopping pump is higher than the pump cavity, and the gas enters the pump cavity from the exhaust port, and the water pressure is connected to the vacuum pipeline, and the function of the check valve is to prevent water from entering the pipeline

- Q: What are the features of axial check valves?

- Axial flow check valve (GB/T 21387-2008) by the standardization of the national valve technical committee (SAC/TC 188). The drafting unit: Shanghai Huatong Valve Co., Ltd., Ningbo aimeike copper valve valve Co. Ltd. Shanghai zhengfeng. Main drafters: Zhang Yonghui, Liu Tienan, Zheng Xuezhen, Chen Tiewang, Meng Aimin. By the national standardization valve technical committee is responsible for the interpretation.TitleAxial flow check valveAuthorState Administration of quality supervision, inspection and Quarantine of the People's Republic of China, China National Standardization AdministrationPublication dateMay 1, 2008LanguagesSimplified ChineseISBNOne hundred and fifty-five billion sixty-six million one hundred and thirty-one thousand two hundred and fiftyForeign nameAxial Flow Check ValvePressChina Standard PressThe number of pagesPage 6FolioSixteenBrandBeijing Jinsong Jian Da Science and technology books Co., Ltd.Axial check valve (GB/T 21387-2008) was published by China standard press.

- Q: What is the check valve?

- Check valve, also known as one-way valve or check valve, its role is to prevent the medium back in the pipeline. Pump water off the bottom valve check valve also belongs to class. The opening and closing parts depend on the flow of the medium and the power is turned on or off by itself. The valve that prevents the backflow of the medium is called a check valve. Check valves belong to the automatic valve, mainly used for one-way flow of media channels, allowing only medium to flow in one direction, to prevent accidents.Check valve (Check Valve): divided by the structure, can be divided into lift check valve, swing check valve and butterfly check valve three. Lift check valve can be divided into vertical and straight through two. Swing check valve is divided into single, double valve and multi flap type of three. Butterfly check butterfly butterfly, double butterfly, butterfly single, more than a few kinds of check valve, in connection form can be divided into thread connection, flange connection, welding and clamp type connection four kinds.

- Q: The principle of the check valve

- Check valve refers to rely on the flow of the media itself and automatically open and close the valve flap, used to prevent media backflow valve, also known as check valve, one-way valve, counter flow valve, and back pressure valve. The check valve belongs to an automatic valve, whose main function is to prevent the backflow of medium, prevent the reverse of pump and drive motor, and release the container medium.

- Q: Which type of check valve should be selected for vertical pipes?

- The check valve on the vertical pipeline shall ensure that the spool goes back to its position when the fluid is stationary and reversed.Optional:Butterfly check valves, pipes of low pressureVertical lift check valve, high pressure resistance, good tightnessSwing check valve: flow must be from the next up, the pipe diameter is unlimited

- Q: Where can I find the good check valve?

- Northeast, I think the quality is better

- Q: How to control the common flue return and smoke return?

- Regular developers submitted, the flue port has installed a check valve for the owners,It is usually closed, and only when the smoke exhauster exhaust smoke will make the check valve open.In addition to the function of the check valve to prevent flue gas recirculation, each hood has a check valve. If you look carefully, you will see that there is a two piece fan at the exit of the smoke machine, which can only be opened in one direction. Its function is the same as the check valve in the flue.Therefore, in fact, there are two soot hoods to prevent smoke from building. Even the first one is broken, and the second are equally effective.Therefore, you can find the reason, whether the check valve two are all broken.

- Q: What does the H/F/P stand for in the check valve H41H/H41F/H41P?

- Respectively, the valve seat sealing surface is made of alloy / fluorine plastic / stainless steel.

- Q: What is the working principle of the flue check valve?

- The utility model relates to a flue check valve, which belongs to an automatic valve, and the main function of the utility model is to prevent the backflow of oil smoke, and only to flow in one direction, and to prevent the airflow from flowing in opposite directions.Simon common flue check valve is the use of aerodynamics and mechanical principles of lever machinery, the use of South Korea's imports of high-quality ABS LG engineering materials for the material.

Send your message to us

CHECK VALVE SWING DUCTILE IRON/ WCB DN40- DN600

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords