Check Valve For Sell Liquid Best Quality Reliable Seal Good Performance 150-2500LB Oil Industry Chemistry Fertilizer Flux

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Check Valves

Check Valves are used in pipes under pressure between Class 150~2500LB, working temperatures﹣196~600℃. They are used in industries including oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

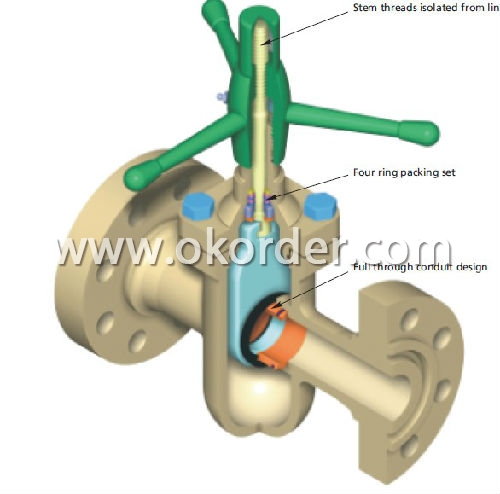

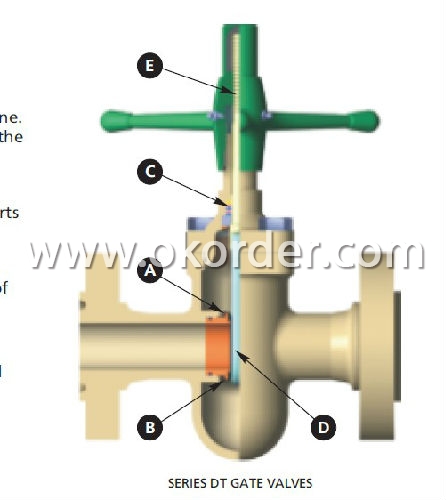

Design Feature of Check Valves

1. The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2. Either soft or hard seal can be selected for the product upon different working conditions. The sealing face is built up with Co-based carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3. Small opening pressure, the disc can be opened fully with a very small pressure differential.

4. Inside-set bolt-bearing structure reduces leakage and reliable use.

5. Class≥1500LB, the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along with the pressure rise so as to ensure the sealing performance.

6. Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirement

Technical Data of Check Valves

| Size | DN40-DN600 |

| Face to Face | DIN 3202 F6 |

| Flange Drilling | EN 1092-2 PN16 |

| Inspection and Test | ISO 5208 |

﹡For all available general design, face to face standard and flange drilling,please kindly contact CNBM directly.

Materials of Parts

| Parts | Description | Material |

| 1 | Body | GG25 |

| 2 | Seat Ring | Brass |

| 3 | Disc Ring | Brass/EPDM |

| 4 | Disc | GG25 |

| 5 | Hanger | GGG50 |

| 6 | Hanger Pin | Stainless Steel |

| 8 | Cover Gasket | Graphite with Soft steel |

| 9 | Cover | GG25 |

﹡For other material request,please kindly contact CNBM directly.

Dimensions of Check Valves

| Size(DN) | L | D | D1 | D2 | b | n-d | H | W.T(kg) |

| 40 | 180 | 150 | 110 | 84 | 18 | 4-19 | 110 | 9 |

| 50 | 200 | 165 | 125 | 99 | 20 | 4-19 | 130 | 13.4 |

| 65 | 240 | 185 | 145 | 118 | 20 | 4-19 | 140 | 17.7 |

| 80 | 260 | 200 | 160 | 132 | 22 | 8-19 | 150 | 20.8 |

| 100 | 300 | 220 | 180 | 156 | 24 | 8-19 | 160 | 29.3 |

| 125 | 350 | 250 | 210 | 184 | 26 | 8-19 | 190 | 47 |

| 150 | 400 | 285 | 240 | 211 | 26 | 8-23 | 210 | 67 |

| 200 | 500 | 340 | 295 | 266 | 30 | 12-23 | 250 | 118.7 |

| 250 | 600 | 405 | 355 | 319 | 32 | 12-28 | 310 | 171.9 |

| 300 | 700 | 460 | 410 | 370 | 32 | 12-28 | 340 | 232.5 |

| 350 | 800 | 520 | 470 | 429 | 36 | 16-28 | 450 | 330 |

| 400 | 900 | 580 | 525 | 480 | 38 | 16-31 | 520 | 460 |

| 450 | 100 | 640 | 585 | 548 | 40 | 20-31 | 550 | 580 |

| 500 | 1100 | 715 | 650 | 609 | 42 | 20-34 | 590 | 700 |

| 600 | 1300 | 840 | 770 | 720 | 48 | 20-37 | 680 | 780 |

- Q: Check valve 1 inches DN25 what do you mean?

- Crown valve pressFirst, an inch equals DN25That is, fixed values to estimate how large a pipeline isOne inch of check valve is mostly copper check valveThe price of I should be around 25 yuan

- Q: What is the structure of the check valve of the screw air compressor?

- Screw air compressor check valve has two kinds: one is to open pressure, one is no need to open the pressureIn the screw compressor, there are generally several places with check valve: intake valve, main engine exhaust, oil return check valve, minimum pressure valve.The check valve is a one-way flow principle

- Q: How much pressure is the check valve h47x-10q?

- Check valve h47x-10q is 1.0MPa pressureAccording to the provisions of the JB/T 308-2004 valve type programming method:H== check valve4== connection: flange7== structure: butterfly typeX== sealing surface material: Rubber10== pressure rating: 1.0MPaQ== body material: ductile iron

- Q: The difference between the micro and slow closing check valve and the silent check valve

- Another micro, slow, closed noise check valve, a little larger flow.Slow closing check valve, also known as check valve or check valve, its role is to prevent the medium back in the pipeline. The opening and closing parts depend on the flow of the medium and the power is turned on or off by itself. The valve that prevents the backflow of the medium is called a check valve. Check valves belong to the automatic valve, mainly used for one-way flow of media channels, allowing only medium to flow in one direction, to prevent accidents. This kind of valve should be installed horizontally in the pipeline.

- Q: What is the difference between the check valve rcvx and SFCV?

- 3, swing type: liquid in the valve straight through, relying on the pressure to open the side of the rotating valve flap, after the loss of pressure, the valve depends on the weight back, the reverse of the liquid pressure closed valve. Other one-way valves (check valves), such as the sewage check valve, air defense explosion-proof valve and liquid use of the principle of the check valve is very similar.

- Q: What's the W in the check valve H44W?

- W represents the sealing surface is the body seal, that is, directly from the valve body out of the sealing surface

- Q: Ask questions about the installation of check valves after water meters

- Generally installed after the water meter. The main reason: if the water point is higher than the water meter installation position, once the pipe network in the absence of water, the remaining water in the pipeline will flow in the direction of the water meter in turn. This will cause the water meter to reverse and cause damage to the water meter. A check valve is installed after the water meter, so that the situation can be avoided.

- Q: Which side of the gate is the fire check valve in the pump room?

- The check valve is installed between the shock absorbing flexible joint and the water outlet control valve at one side of the water outlet pipe of the water pump

- Q: What is the reason that the check valve does not stop water?

- 7, when installing check valve, should pay special attention to medium flow direction, should make medium normal flow direction and the direction of the arrow on the valve body is consistent, otherwise it will cut off the normal flow of media. Valve should be installed at the bottom of the pump suction pipe.The general formula 8, lift check valve should be installed in horizontal pipe, vertical lift check valve and bottom valve is usually installed in a vertical pipe on the road, and the bottom-up flow of media.9, the check valve closes, will produce water hammer in pipeline pressure, will lead to serious damage to the valve and piping or equipment, especially for the big pipe or high pressure pipeline, it should pay attention to those who use check valve.

- Q: What does the check valve "H64" and "H14" mean?

- H check valve6 welding connection1 threaded connection4 swing check valveJB/T308-2004< valve type programming method >There should also be sealing surface material code and nominal pressure level

1. Manufacturer Overview

| Location | Beijing,China |

| Year Established | 1986 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Africa, Asia, America, Europe, Middle East, West Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Beijing |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 498 People |

| Language Spoken: | English,Chinese |

| b) Factory Information | |

| Factory Size: | 42000 square meters |

| No. of Production Lines | Above 20 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Check Valve For Sell Liquid Best Quality Reliable Seal Good Performance 150-2500LB Oil Industry Chemistry Fertilizer Flux

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords