Ductile Iron Check Valve DN1400 Quality Guarantee China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Technical Date | Material Specification | ||

Nominal Diameter | DN40-DN1000 | Valve Body | Cast Iron or Ductile Iron |

Nominal Pressure | PN10/PN16 | Valve Disc | Cast Iron or Ductile Iron or Stainless Steel |

Operation Temperature | -40°C~225°C | ||

Flange Driling Standard | EN 1902-2 PN10/16 | Seal Material | EPDM OR NBR |

Suface Treatment | Painting | Valve Spring | Stainless Steel |

Quick Details

| Standard or Nonstandard: | OEM | Structure: | Check | Pressure: | High Pressure, Low & high pressure |

| Power: | Manual | Material: | Casting, Ductile iron | Temperature of Media: | Medium Temperature |

| Media: | Water | Port Size: | 2"-48" | Place of Origin: | Shanxi, China (Mainland) |

| Model Number: | WINDUS-BV-160409416 | Brand Name: | WINDUS | Application: | General, Industry & Metropolis water treatment |

| Product name: | API 594 Cast Iron Double Door Wafer Check Valve | Dimension Range: | 3"~48" | Certification: | UL, NSF61 |

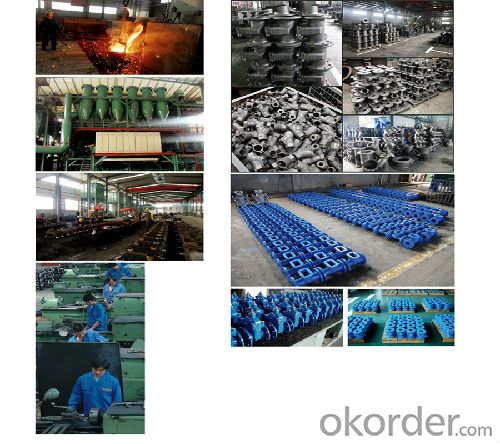

| Testing equipment: | Hydrolic testing machinging | Process: | Sand casting, machining, rubber lining | Port: | Tianjing, qingdao, Dalian,Shanghai |

| Place of Origin:: | Shanxi, China (Mainland) |

Packaging & Delivery

| Packaging Details: | Plywooden case, metal pallet, iron frame |

API 594 Cast Iron Double Door Wafer Check Valve

| Type | API 594 Cast Iron Double Door Wafer Check Valve |

| Material | Body: gray iron ASTM A126 class B, ductile iron (optional) ASTM A536 grade 65-45-12 Disc:Stainless steel, AL Bronze alloy, ductile iron Seat: EPDM, buna-N |

| Main Process | Resin sand casting |

| Surface finish | Epoxy paint |

| Heat treatment | NONE |

| Weight Range | 10~200 kg |

| Dimension Range | 2"~48" |

| Application | Industry & Metropolis water treatment |

| Certification | UL, NSF61 |

| Packing Detail | plywood box |

| Delivery time | 30 days after order |

| Equipment | NC Lathing machine, NC Boring machine, Drilling machine |

| Testing equipment | Hydrolic testing machinging |

| Inspection | hydro test, shell test, seal test |

| Production capacity | 10/60/100 |

| Market | US |

| MOQ | 1 |

| Port | TianJing,qingdao,shanghai,beijing |

- Q: Automatic water tower water reflux, plus a check valve not supposed

- Check the direction of the installation is correct, check valve quality is good, you can install two check valve. Check valve refers to rely on the flow of the media itself and automatically open and close the valve flap, used to prevent media backflow valve, also known as check valve, one-way valve, counter flow valve, and back pressure valve. The check valve belongs to an automatic valve, whose main function is to prevent the backflow of medium, prevent the reverse of pump and drive motor, and release the container medium.

- Q: Check valve note BC/PISTON: SPR-L what does that mean?

- BC==Bolted Cover/ bolted bonnetPISTON== lifting typeSPR-L==Spring-loaded/ is loaded with springsTogether, it is: a spring-loaded check valve. Bolted bonnet (this is common)

- Q: Should the kitchen check be mounted on the wall or on the hood?

- Buy their own check valve is generally in the wall of the hole, the hood of the smoke machine, usually with a check valve.

- Q: The difference between backflow preventer and check valve

- The backflow preventer consists of two separated check valves and a drain valve. Due to the local head loss of the check valve, the pressure in the middle cavity is always lower than the pressure at the inlet. This pressure difference causes the drain valve to be closed and the pipe is in normal water supply.

- Q: What is the function of the check valve in the pipeline?

- Check valve, also known as one-way valve or check valve, refers to rely on the media itself flow and automatically open and close the valve flap, used to prevent the media back flow valve, also known as check valve, Dan Xiangfa, counter flow valve and back pressure valve.Effect:The function is to prevent backflow of medium in the pipeline. Pump water off the bottom valve check valve also belongs to class. The opening and closing parts depend on the flow of the medium and the power is turned on or off by itself. The valve that prevents the backflow of the medium is called a check valve. Check valves belong to the automatic valve, mainly used for one-way flow of media channels, allowing only medium to flow in one direction, to prevent accidents.Check valve installed in the pipeline system, the main role is to prevent media backflow, check valve is a kind of pressure on the media to open and close the automatic valve. The clip type check valve applies to nominal pressure PN1.0MPa~42.0MPa and Class150~25000; nominal diameter DN15~1200mm and NPS1/2~48; work temperature -196~540 degrees of various pipelines, used to prevent medium flow back. By choosing different materials, it can be applied to many mediums such as water, steam, oil, nitric acid, acetic acid, strong oxidizing medium and uric acid.

- Q: What are the differences between the vertical check valve and the horizontal check valve?

- The main difference is whether the valve center and valve seat are placed horizontally or vertically. It is usually designed with the pipe

- Q: How can the PPR pipe be connected to the check valve?

- Check valve refers to rely on the flow of the media itself and automatically open and close the valve flap, used to prevent media backflow valve, also known as check valve, one-way valve, counter flow valve, and back pressure valve.

- Q: How do I use the triangle and check valves?

- The triangle valve is used for connecting taps and water equipment. Check valves are used to prevent backflow of water.

- Q: Our unit pump outlet check valve installed in the vertical pipe, the use of the valve to stop the valve is more serious impact, is not installed, the valve should be how to install it?

- Installation method of pump outlet check valve:1, swing check valve is generally installed in the horizontal pipe: for caliber DN~80mm check valve, can also be installed in theVertical or upward sloping pipe.2, the straight through lift check valve should be installed on the horizontal pipe;3, vertical lift check valve must be installed on the vertical pipe, the medium for bottom-up flow.As the check valve is easy to damage, therefore, should be installed near the pump outlet valve, in the upper part of the check valve with a cut-off valve (general use of ball valve or gate valve), easy to overhaul. To facilitate the relief of the check valve before disassembly, the relief valve shall be installed between the check valve and the shut-off valve.

- Q: How many kinds of structure are there in the check valve?

- 1. The structure of the lift check valve is similar to that of the globe valve. Its valve moves up and down along the central line of the channel. The action is reliable, but the resistance of the fluid is large. It is suitable for small caliber occasions. The lift type check valve has an air passage type

Send your message to us

Ductile Iron Check Valve DN1400 Quality Guarantee China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords