Ductile Iron Check Valve DN200 High Quality and Reasonable Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 set

- Supply Capability:

- 4500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Usage/Applications Of Ductile Iron Check Valve

Check valve is to rely on the flow of the media itself and automatically open, close the valve flap, used to prevent the media back valve, also known as the check valve, Dan Xiangfa, counter flow valve, and back pressure valve. Check valve is an automatic valve, its main role is to prevent the media back, to prevent the pump and drive motor reversal, as well as the release of the container medium.

Technical Date | Material Specification | ||

Nominal Diameter | DN40-DN1000 | Valve Body | Cast Iron or Ductile Iron |

Nominal Pressure | PN10/PN16 | Valve Disc | Cast Iron or Ductile Iron or Stainless Steel |

Operation Temperature | -40°C~225°C | ||

Flange Driling Standard | EN 1902-2 PN10/16 | Seal Material | EPDM OR NBR |

Suface Treatment | Painting | Valve Spring | Stainless Steel |

Quick Details

| Standard or Nonstandard: | Standard | Structure: | Other | Pressure: | Medium Pressure |

| Power: | Hydraulic | Material: | Casting | Temperature of Media: | Normal Temperature |

| Media: | Water | Place of Origin: | China (Mainland) | Model Number: | 34 |

| Brand Name: | CNBM |

- Q:The principle of the check valve

- Check valve refers to rely on the flow of the media itself and automatically open and close the valve flap, used to prevent media backflow valve, also known as check valve, one-way valve, counter flow valve, and back pressure valve. The check valve belongs to an automatic valve, whose main function is to prevent the backflow of medium, prevent the reverse of pump and drive motor, and release the container medium.

- Q:The difference between the plunger type check valve and the lift check valve

- The two elastic seals are separated by a collar and secured to the sealing ring around the plunger by the load exerted by the valve cover nut on the valve cover. Elastic ring can be replaced, you can use a variety of materials, the valve is mainly used for "open" or "off", but with a special form of plunger or special ring can also be used to adjust flow.

- Q:Is there a check valve with a relief valve above?

- You can be sure to answer, no such installationThe fire check valve is not the same as the relief valve.

- Q:What does the check valve "H41F" mean?

- According to the provisions of the JB/T 308-2004 valve type programming method:H== check valve4== connection: flange type1== structure form: lifting typeF== sealing surface material: fluorine plastic

- Q:What is the function of the check valve?

- The function of the check valve is to prevent the medium from flowing back! Check valves, which are commonly known as check valves! Backflow of medium will cause the reverse of pump impeller, which may lead to the burnout of pump! Pumps used in industry are expensive nowadays! Ha-ha! The check valve just protects the pump and piping!

- Q:What is the air pipe check valve?

- One-way valve, one-way flow, to prevent negative pressure reflux.

- Q:I would like to ask you the following questions: Recently, the newly purchased three Lin electric water heater, installed in the upper layer of the five bathrooms, a faucet, that is left to wring out hot water, to the right to wring out cold water, mixed type.1 when there is no safety valve, the hot and cold flow is normal, but the check valve is dripping.2 manufacturers said that the high level to safety relief valve, dripping water and this also concerned, it took more than 100 safety valve, on the cold water pipe, but since then, hot water flow and its small, cold water normal, the check valve is still dripping.3 excuse me, check valve, check valve, safety valve is not a thing? Is it just a different name?4 is the relief valve the same as the relief valve?Now it's really a tough one. How do you solve the problem of small drop of water and hot water flow? The manufacturer said the pressure, but I very cold water washed!Thanks for the answer!

- Check valve and check valve is to prevent backflow of water, the valve is used for pressure relief, when the water heater pressure is too high, the pressure through the pressure relief valve and pressure relief valve on the other: for water, the quality is not good, the main problems for the water pressure is too low to cause, and check valve and pressure relief valve will further reduce the pressure, you can try to check off a try, I think the check valve is useless. If not, just add a booster pump to the cold water inlet.

- Q:What is the difference between check and check valves? Check and check valves?

- 3, swing type: liquid in the valve straight through, relying on the pressure to open the side of the rotating valve flap, after the loss of pressure, the valve depends on the weight back, the reverse of the liquid pressure closed valve. Other one-way valves (check valves), such as the sewage check valve, air defense explosion-proof valve and liquid use of the principle of the check valve is very similar

- Q:Why can't the check valve on the air pipe be used when the wind speed is less than 8 meters?

- First of all, you must understand the working principle of the check valve, indeed, as you said, you can adjust the position of the hammer by adjusting the position of the drop hammer.If you are in their own design and production, consider the thickness of the blade, drop hammer size, weight, and other parameters considered.Hope to be of help to you!

- Q:Why is the water ring vacuum pump equipped with check valves?

- The check valve is a one-way valve, the instantaneous vacuum of the stopping pump is higher than the pump cavity, and the gas enters the pump cavity from the exhaust port, and the water pressure is connected to the vacuum pipeline, and the function of the check valve is to prevent water from entering the pipeline

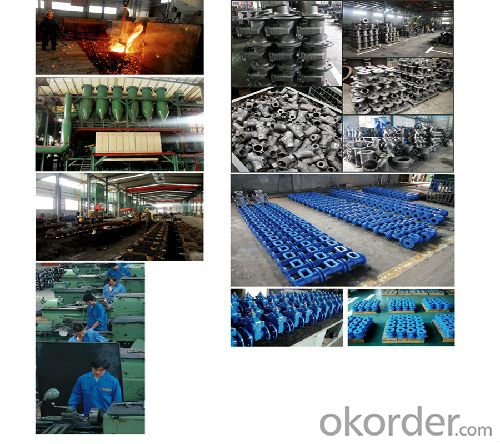

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ductile Iron Check Valve DN200 High Quality and Reasonable Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 set

- Supply Capability:

- 4500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords