CHECK VALVE API FORGING WCB/CF8/CF8M DN50-DN300

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Standard or Nonstandard: | Standard | Structure: | Check | Pressure: | Medium Pressure |

Power: | Manual | Material: | Stainless Steel | Temperature of Media: | Medium Temperature |

Media: | Water | Port Size: | DN50-300mm | Place of Origin: | Tianjin, China (Mainland) |

Model Number: | F7372 | Brand Name: | CMAX | Application: | General |

Item name: | API Forging Check Valves,check valve types,check valve 10 inch | Connection: | Flange | Key words: | check valve |

Usage: | water | Body material: | Carbon Steel, Stainless Steel | Working Temperature: | -40°C~225°C |

Pressure Class: | PN10/16 | Sample: | Packing: | Plywood Case For Check Valve | |

Applicable medium: | water, oil, gas |

Packaging & Delivery

| Packaging Details: | PVC package or wooden cases, also according to our customer's requirement.Custom made is accepted.. |

| Delivery Detail: | within 30 days after receiving advancing payment |

Technical Date | Material Specification | ||

Nominal Diameter | DN40-DN1000 | Valve Body | Cast Iron or Ductile Iron |

Nominal Pressure | PN10/PN16 | Valve Disc | Cast Iron or Ductile Iron or Stainless Steel |

Operation Temperature | -40°C~225°C | ||

Flange Driling Standard | EN 1902-2 PN10/16 | Seal Material | EPDM OR NBR |

Suface Treatment | Painting | Valve Spring | Stainless Steel |

- Q:How to use the check valve when the size of the pressure?

- 1) check valve: generally applicable to clean medium, should not be used for containing solid particles and viscosity medium.2), for the low pressure below DN50mm check valve, check valve should be selected on the clip, vertical lift check valve; for DN is greater than 200mm, less than 1200mm in the low pressure check valve, should use micro slow close check valve, water hammer eliminating buffer device with valve and check valve; for the low pressure DN is greater than 50mm, less than 2000mm should use check valve, butterfly valve and swing check valve.3), micro slow close check valve for easy to produce water hammer piping on the micro resistance slow closing system can well eliminate the media generated when the water hit counter, but limited by the temperature and pressure, generally used in low temperature pipe.4) for the closing of the water shock or small impact of the water pipeline, it is appropriate to use micro resistance slow closing check valve and buffer butterfly check valve.

- Q:The air pipe is equipped with a check valve

- The weight of the valve or the gravity of gravity to maintain the valve in the open state of balance, the principle of the same, are heavy torque control of the door opening and closing. Inside and outside the air pressure to destroy the balance, automatic door opening and closing control. An example of simply closing a valve plate by gravity, as in a vertical check valve (Dan Liufa) in a water supply pipe.

- Q:Check valve symbols?

- The check valve is divided into three kinds: lift check valve, swing check valve and butterfly check valve:1. lift check valve is divided into two types of vertical and horizontal.2. swing check valve is divided into single, double flap and multi flap type of three.3. butterfly check valve is straight through type.The above types of check valves can be classified into thread connection, flange connection, welding connection and clamp connection in connection forms of four kinds.

- Q:The difference between slow closed valve and open the valve

- The difference is mainly that the opening and closing of the slow closing check valve depend on the external and external forces to perform the slow opening and closing (usually hydraulic cylinder or pneumatic cylinder). The swing check valve is opened and closed by the pressure of the pipe medium to complete the opening and closing (and the pressure of the pipeline).

- Q:What are the types of check valves?

- The check valve is divided into three kinds: lift check valve, swing check valve and butterfly check valve:1. lift check valve is divided into two types of vertical and horizontal.2. swing check valve is divided into single, double flap and multi flap type of three.3. butterfly check valve is straight through type.The above types of check valves can be classified into thread connection, flange connection, welding connection and clamp connection in connection forms of four kinds.Texture of material1. cast iron check valve2. brass check valve3. stainless steel check valve4. carbon steel check valve

- Q:I use water pump pumping 78 meters deep underground water, the pipe is 2.5 inches large, with ordinary check valve, water is always sucked back, I would like to ask what method or what kind of check valve to be selected (check valve to be installed on the side of the pump)

- 1, do not use ordinary ball check valve, rubber check valve, quick response, but it is not very durable2, vacuum tank3, I think the most benevolent is, get an auxiliary start pump, small kind of, the head is not too high, connect the municipal pipe network, open the main pump before the auxiliary pump irrigation. But the premise is that your main pump is a centrifugal pump

- Q:Is the check valve the same?

- Same。 Call a difference; a thing. You come to our store to have a look.

- Q:Circulating water check valve, I want to ask is not greater than DN600, you can use HBH747H hydraulic butterfly valve closed butterfly valve, less than DN600 of HD43X slow butterfly butterfly check valve, what does hydraulic check mean? Need hydraulic?

- If it is water medium butterfly valve, in fact, the same, are used to prevent the media back of the valve, on the models are manufacturers themselves, there is no uniform standard, but only in the use of media on the difference.Butterfly buffer check valve is to rely on the flow of the media itself and automatically open and close the valve, used to prevent the media back of the valve, also known as check valve, one-way valve, counter flow valve, and back pressure valveMicro resistance slow closing check valve, also known as check valve, its role is to prevent the medium back flow in the pipeline.

- Q:Should the flue check valve be made by the civil team or the installation team?

- Internal construction, check the inner ring outside the cement glue installed

- Q:What is the difference between the check valve and the check valve?

- The same thing is the flue check valve. We need to contact the manufacturer

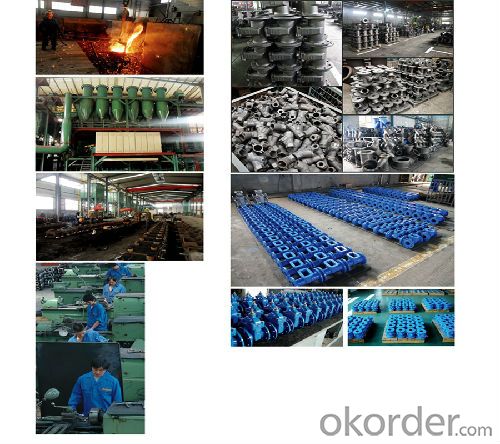

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CHECK VALVE API FORGING WCB/CF8/CF8M DN50-DN300

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords