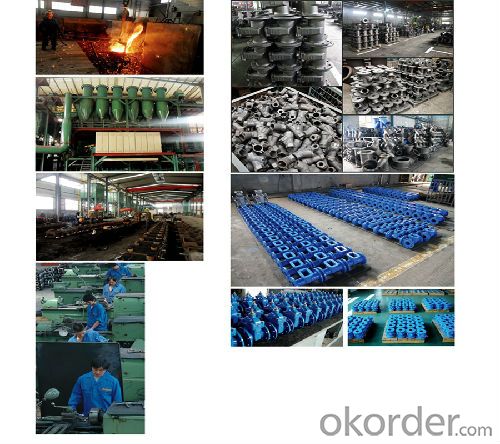

CHECK VALVE SWING TYPE SINGLE DISC DUCTILE IRON DN50- DN400

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Standard or Nonstandard: | Standard | Structure: | Check | Pressure: | Medium Pressure |

Power: | Hydraulic | Material: | Casting | Temperature of Media: | Medium Temperature |

Media: | Water | Port Size: | DN50-400 | Place of Origin: | China (Mainland) |

Model Number: | H76X | Brand Name: | CMAX | Application: | General |

Name: | Single disc wafer type check valve | Standard: | API,DIN,JIS,BS, | Medium: | wafer,oil,gas,Acid,alkali |

Valve body material: | cast iron,Stainless steel,brass | Size: | 2"~16" or DN50~DN400 | Advantage: | no leakage |

Packaging & Delivery

Packaging Details: | Veneer board boxes |

Name:Wafer type check valve,single door check valve,wafer type swing check valve.

Valve body:cast iron ,GG25,GGG40,CF8M

1.Working pressure:1.6Mpa

2.Testing :API598 DIN3230

3.Flange standard

DIN2501 PN10/16

BS4504 PN10/16

BS10 TABLE "D"/"E"

JIS2220 10K/16K

ANSI125/150

4.Face to face

ANSI125/150

DIN3203 K3-1999

Technical Date | Material Specification | ||

Nominal Diameter | DN40-DN1000 | Valve Body | Cast Iron or Ductile Iron |

Nominal Pressure | PN10/PN16 | Valve Disc | Cast Iron or Ductile Iron or Stainless Steel |

Operation Temperature | -40°C~225°C | ||

Flange Driling Standard | EN 1902-2 PN10/16 | Seal Material | EPDM OR NBR |

Suface Treatment | Painting | Valve Spring | Stainless Steel |

- Q: What happens when the check valve is broken?

- Check valve is broken, there will be back water, down pressure, serious will produce pump reversal, burning motor

- Q: I installed here in the water pump inlet, water pump with a 100 tons of water tank, there are many pumps, long time running, the pump will heat the cylinder, there is no water in the cylinder, the pressure does not go. The water pump is imported. Is the check valve broken or is the installation position wrong?

- Is the check valve installed at the inlet or outlet of the pump? Mainly to see whether the water pump suction or press in? There are other factors, such as pressing first class. Generally both sides will be installed, each has its own role, but to look at the type of your pump and other parameters, you describe the situation is too simple to point out in detail, such as specific is that a few, or all? Also, how high the pump needs to be played, and the pressure is often determined. The check valve is installed on the water outlet side of the pump. I simple analysis may be the following reasons, need to have a simple to complex one by one investigation, 1, electrical specifications are matching? 2 、 the pump has air intake or air not discharged 3, piping layout is reasonable? 4, check valve installed counter, or check valve did not open, stuck,? This situation is rare, the general novices easily made 5, you missed the judgment? ------------------- most likely the breath, or simply not enough water, the check valve can be judged according to the type of installation position.

- Q: What's the difference between a stop valve and a check valve? Is it a valve?

- A check valve is a valve that automatically prevents the flow of fluid. The disc of the check valve is opened under the action of fluid pressure, and the fluid flows from the inlet side to the outlet side. When the inlet side pressure is lower than the exit side, the valve automatically closes under the influence of fluid pressure, gravity and other factors to prevent fluid flow backwards. The function of this type of valve is to allow the medium to flow in one direction and to prevent flow in the direction. Usually the valve is automatically work, fluid pressure flow in one direction, the valve open; the opposite direction of fluid flow by gravity, fluid pressure and valve closing effect on the valve seat, thereby cutting off flow. Among them, the check valve belongs to this type of valve, which includes swing check valve and lift check valve. The swing check valve has a hinge mechanism and a gate like valve free against the inclined seat surface.

- Q: Is the hdf41x 1.6Mpa a check valve?

- Backflow prevention device according to tap water supply equipment, especially drinking water pipe back to serious pollution, and effectively prevent the pollution device under the condition of a strictly limited hydraulic control assembly pipeline water only one-way flow of development, its function is to prevent backflow pipeline media in any condition, in order to avoid the purpose of backflow pollution.

- Q: What type of check valve is the h61y-40 check valve?

- I. lift check valves: check valves that slide along the vertical centerline of the valve body. The lift check valves can only be installed on the horizontal pipe. The disc can be used in the high pressure small bore check valve. The valve body of the lift check valve is the same as the cut-off valve (which can be used with the stop valve), so it has a large coefficient of fluid resistance. The structure is similar to the cut-off valve, the valve body and the disc are the same as the cut-off valve. The lower part of the upper valve and the valve cover processing guide sleeve, the valve in the valve lift free guide simple simple light driven, when the medium downstream, the valve thrust open by the media, when the media stopped flow, the valve by the self vertical landing on the seat, preventing the media from the upstream effect. Straight through lift type check valve medium channel with import and export channel direction perpendicular to the valve seat; vertical lift check valve, the media import and export channel in the direction of the same direction with the valve seat, the flow resistance is smaller than the straight through.

- Q: The difference between check valve and check valve

- 1, one-way valve: is a typical seat valve, one-way valve Check, Valve, also known as check valve or check valve. Used in hydraulic systems to prevent reverse flow of oil flow. There are two one-way valve one-way and right angle type. Straight through one-way valves are threaded and installed on the pipe line. The right angle one-way valve has threaded connections, plate connection and flange connection in three forms. Liquid control check valve, also known as blocking valve or pressure valve, which is the same as one-way valve, used to prevent reverse flow of oil. But in the hydraulic circuit needs the oil flow reverse flow, but also can use the control oil pressure, opens the one-way valve, causes the oil flow to be possible to flow in two directions. The hydraulic control check valve adopts a conical valve core, so the sealing performance is good. When the closed oil circuit is required, the valve can be used as the one-way locking of the oil circuit to maintain the pressure. Liquid control check valves control the leakage of oil, there are two types of internal and external leakage. In the oil flow reverse outlet, no back pressure in the oil pipeline can be used to vent type; otherwise, need to leak type, in order to reduce the control oil pressure2, check valve is only one kind of valve, it can be said that one-way valve is a kind of check valve,

- Q: What's the difference between a throttle valve and a check valve? Are they the same?

- The same valve, but the effect is entirely different.The so-called "check back" is to let the fluid in the pipeline can only flow in one direction, can not let it return, so it is also called one-way valve. It works automatically.

- Q: What is the function of the check valve installed in the water meter before entering the residential water?

- Generally installed after the water meter. The main reason: if the water point is higher than the water meter installation position, once the pipe network in the absence of water, the remaining water in the pipeline will flow in the direction of the water meter in turn. This will cause the water meter to reverse and cause damage to the water meter. A check valve is installed after the water meter, so that the situation can be avoided.The main function of the check valve is to prevent the backflow of the medium, prevent the reverse of the pump and drive motor, and release the container medium. The check valve can also be used to provide a supply to the auxiliary system where the pressure may rise above the system pressure.

- Q: What is the difference between the check valve and the check valve?

- The same thing is the flue check valve. We need to contact the manufacturer

- Q: Is the check valve the same?

- Same。 Call a difference; a thing. You come to our store to have a look.

Send your message to us

CHECK VALVE SWING TYPE SINGLE DISC DUCTILE IRON DN50- DN400

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords