Double Sided Self Adhesive Tape

Double Sided Self Adhesive Tape Related Searches

Industrial Double Sided Adhesive Tape Double Sided Floor Tape Waterproof Double Sided Tape Double Sided Carbon Tape Double Sided Foam Tape Double Sided Cellophane Tape Double Sided Sticky Tape Dispenser Two Sided Foam Tape Removable Double Sided Mounting Tape Industrial Strength Double Sided Tape Double Sided Tape For Scrapbooking 50Mm Double Sided Tape Double Sided Tape High Temperature Thermally Conductive Double Sided Tape Heat Resistant Double Sided Foam Tape Double Coated Foam Tape Low Tack Double Sided Tape Best Double Sided Tape For Woodworking Strongest Double Sided Tape Available Strongest Two Sided Tape Conductive Adhesive Tape Adhesive Backed Foam Tape One Sided Foam Tape Industrial Adhesive Tape Binding Tape Pressure Sensitive Adhesive Tapes Aluminum Tape Custom Printed Duct Tape Sticky Mesh Tape Teflon Adhesive TapeDouble Sided Self Adhesive Tape Supplier & Manufacturer from China

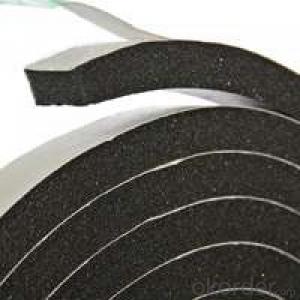

Double Sided Self Adhesive Tape is a versatile product that features adhesive on both sides, providing a strong bond between materials. This type of tape is made from various materials, such as acrylic, rubber, or foam, and is available in different thicknesses and widths to suit a wide range of applications. It is commonly used for bonding, mounting, and sealing purposes in various industries, including automotive, electronics, and construction.The Double Sided Self Adhesive Tape is widely used in various applications, such as attaching trims, mounting mirrors, and securing decorative elements. It is also used for bonding different materials like metal, plastic, glass, and wood, making it a popular choice for both indoor and outdoor use. The tape's strong adhesion ensures that the bonded items remain securely in place, even under challenging conditions.

Okorder.com is a reputable wholesale supplier of Double Sided Self Adhesive Tape, offering a vast inventory of this product to cater to the needs of businesses and individuals alike. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Double Sided Self Adhesive Tape they provide is of the highest standard, making it a reliable choice for various bonding and mounting projects.

Hot Products